Nitrogen-doped carbon flexible paper and its preparation method and application

A carbon-flexible, nitrogen-doped technology, used in textiles and papermaking, electrical components, battery electrodes, etc., can solve the problems of low energy density of self-supporting electrodes, difficult to scale preparation, and harsh conditions, and achieve excellent oxygen reduction catalysis. performance, guaranteed bending modulus range, good bending flexibility effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] A nitrogen-doped carbon flexible paper is prepared by the following method:

[0035] (1) Low temperature thermal oxidation: the thickness is 2cm, the density is 8mg / cm 3 The melamine foam is placed in an electric furnace, heated to 250°C in an air atmosphere, and kept at this temperature for 0.5h;

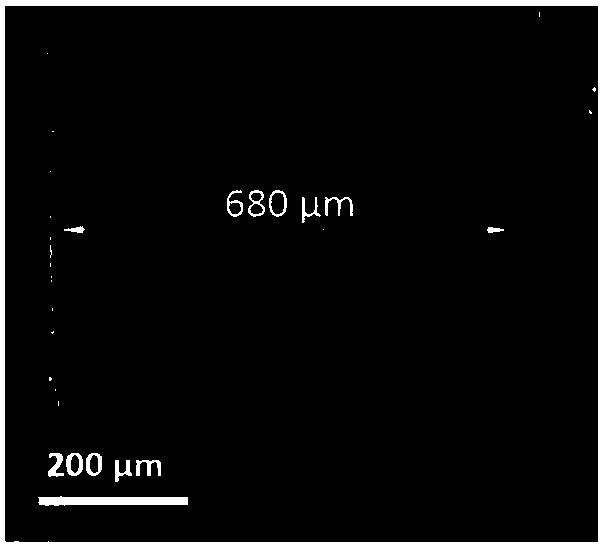

[0036] (2) High-temperature heat treatment: the melamine foam through low-temperature thermal oxidation in step (1) is placed in an electric furnace, and under the protection of nitrogen, 5 g / cm2 is applied to the melamine foam through low-temperature thermal oxidation. 2 After mechanical pressure, heat up to 900°C at a heating rate of 3 , the flexural modulus of paper-1 measured by the three-point bending method is 20.5kPa, the conductivity measured by the four-probe method is 0.15S / cm, and the thickness of the paper-1 is 680 microns (such as figure 1 shown), with an interconnected carbon network structure (such as figure 2 shown).

Embodiment 2

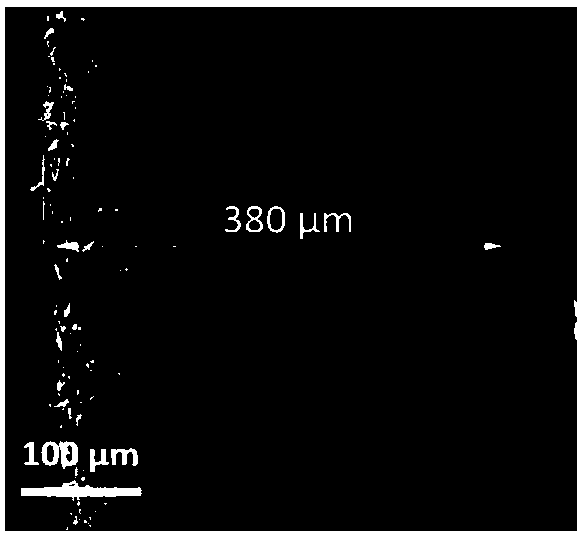

[0038] The operation method of embodiment 2 is substantially the same as embodiment 1, and difference is that in step (2), mechanical pressure is 20g / cm 2 , the nitrogen-doped carbon flexible paper is marked as paper-2; the density of paper-2 is weighed and calculated to be 90.5mg / cm 3 , the flexural modulus of paper-2 measured by three-point bending is 46kPa, the conductivity measured by four-probe method is 0.56S / cm, and the thickness of this paper-2 is 380 microns (such as image 3 shown), with an interconnected carbon network structure (such as Figure 4 shown).

Embodiment 3

[0040] The operation method of Example 2 is basically the same as that of Example 1, the difference is that in step (2), heating to 1000°C and keeping it warm at this temperature for 0.5h, the obtained nitrogen-doped carbon flexible paper is marked as Paper-3; The density of weighing test paper-3 is 25.3mg / cm 3 , the flexural modulus of paper-3 measured by three-point bending is 26kPa, and the conductivity measured by four-probe method is 1.2S / cm. Scanning electron microscopy shows that the thickness of paper-3 is 342 microns, with interconnected carbon network structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| flexural modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com