Method for treating organic waste gases by utilizing rotary wheel

A technology of organic waste gas and treatment methods, which is applied in the direction of gas treatment, separation methods, chemical instruments and methods, etc. It can solve the problems of secondary pollution, affecting the regeneration of adsorbents, and the inability to effectively treat industrial waste gas, so as to achieve cost saving and good regeneration Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0044] The concentration is 800mg / m 3 , the wind volume is 50000m 3 / h of waste gas, which contains organic gases: formaldehyde, methanol.

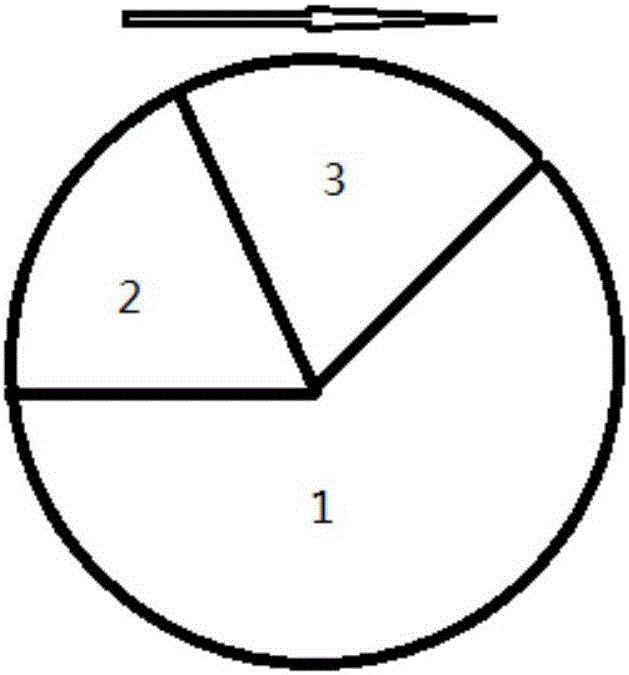

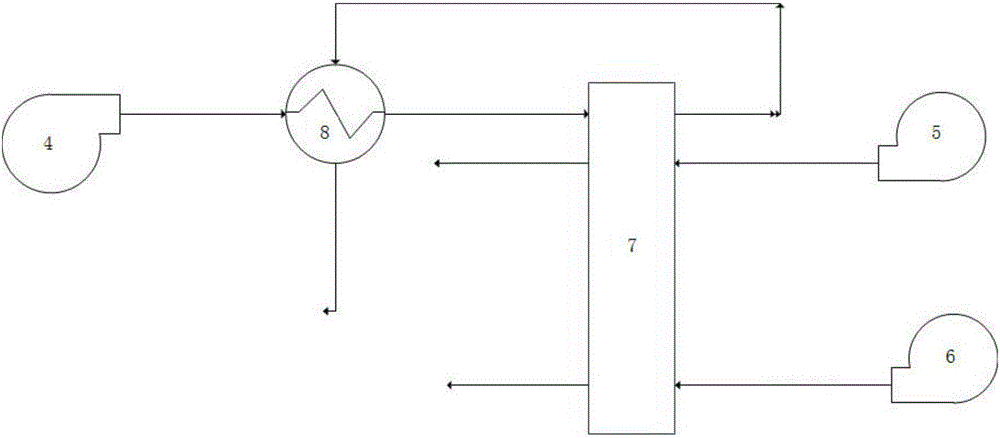

[0045] (1) Adsorption: supporting catalyst Pt and molecular sieve adsorbent are loaded on the support layer made of polymer fiber polyimide, the quality of Pt is 50g, the quality of molecular sieve is 5kg, and the catalyst consumption is 1% of adsorbent. The runner runs clockwise at a speed of 3 revolutions per hour, exhaust gas is adsorbed through the adsorption area of the runner, and the exhaust gas after adsorption is directly discharged into the atmosphere, and the removal rate of organic matter reaches 99%.

[0046] (2) Catalytic decomposition: When the runner moves to the catalytic decomposition zone, the 3 / h hot air, the adsorbed formaldehyde and methanol are decomposed into H under the action of high temperature and catalyst 2 O and CO 2 , the content of organic matter in the exhaust gas is less than 10mg / m 3 , the wheel ...

Embodiment 2

[0049] The concentration is 300mg / m 3 , air volume is 5000m 3 / h of waste gas, which contains organic gases: petroleum ether, toluene.

[0050] (1) Adsorption: Load 1kg of catalyst Mn on a support layer made of ceramic fibers 0.5 Cu 0.5 o 1.1 / TiO 2 , Mn in the catalyst 0.5 Cu 0.5 o 1.1 The mass fraction is 10%, zeolite is used as the adsorbent, the mass is 5kg, the runner runs clockwise at a speed of 1 revolution per hour, the exhaust gas is adsorbed through the adsorption area of the runner, the tail gas is directly discharged into the atmosphere, and the removal rate of organic matter reaches 99%.

[0051] (2) Catalytic decomposition: When the runner moves to the catalytic decomposition zone, the 240°C, 250m 3 / h hot air, the adsorbed petroleum ether and toluene are decomposed into H under the action of high temperature and catalyst 2 O and CO 2 , the content of organic matter detected in the exhaust gas is less than 5mg / m 3 , the wheel is regenerated.

[005...

Embodiment 3

[0054] The concentration is 300mg / m 3 , the wind volume is 6000m 3 / h of waste gas, which contains organic gas: dichloroethane.

[0055] (1) Adsorption: Load 1kg catalyst TiO on a support layer made of ceramic fibers 2 , using zeolite as the adsorbent, the mass is 6kg, the catalyst accounts for 14%, the runner runs clockwise at a speed of 2 revolutions per hour, the waste gas is adsorbed through the adsorption area of the runner, the tail gas is directly discharged into the atmosphere, and the removal rate of organic matter reaches 90% %.

[0056] (2) Catalytic decomposition: when the runner moves to the catalytic decomposition zone, the 3 / h hot air, the adsorbed dichloroethane is decomposed into HCl and CO under the action of high temperature and catalyst 2 , the organic content detected in the exhaust gas is about 30mg / m 3 , dichloroethane could not be completely decomposed under this condition, and the runner was regenerated.

[0057] (3) Cooling: When the runner m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com