Gas foam remover for acetylene hydrogenation type ethylene preparation packing bubbling bed

An acetylene hydrogenation and demister technology, which is applied in the fields of hydrogenation to hydrocarbon production, chemical instruments and methods, catalysts, etc., can solve problems such as single function and complex structure, and achieve the effects of prolonging service life, simple structure and cost saving.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

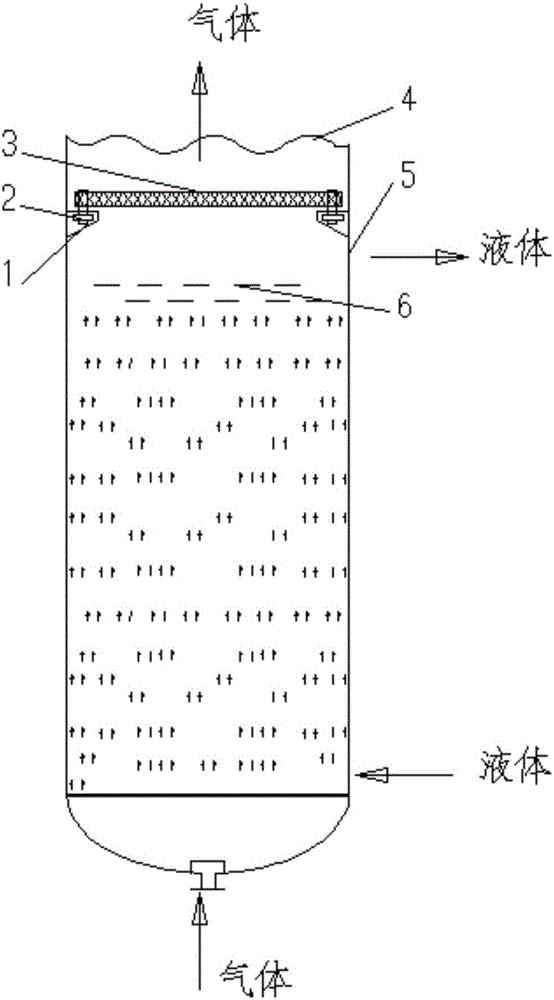

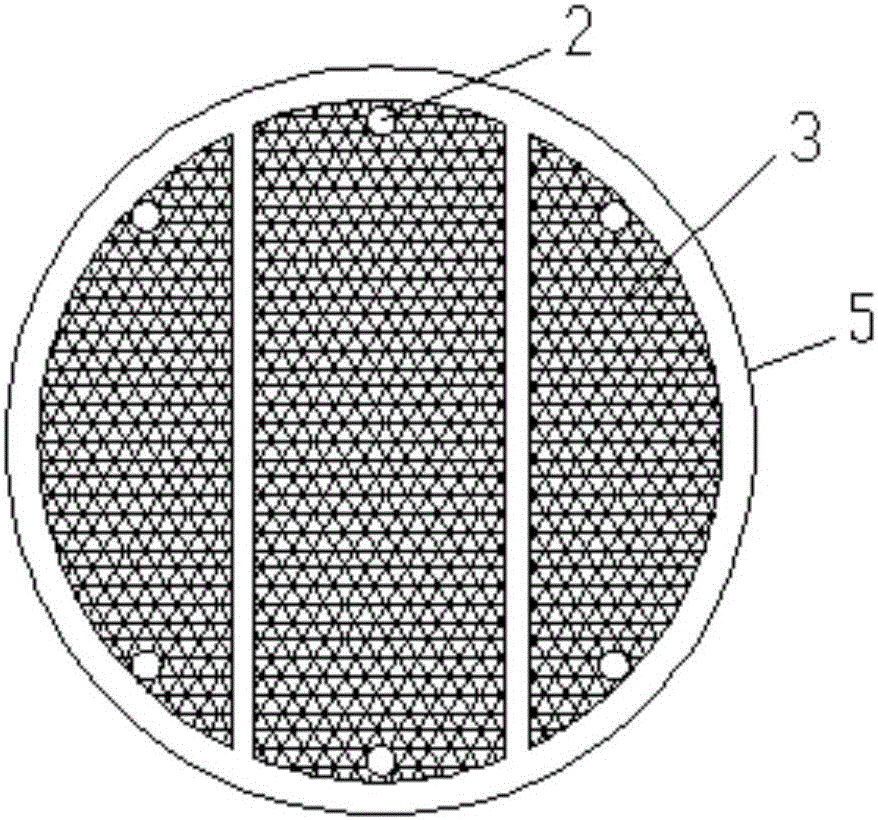

[0036] The gas demister structure of the present embodiment is as figure 1 and figure 2 as shown,

[0037] The mesh number of the screen 3 is 20 mesh, the material is high-strength polytetrafluoroethylene, and the number of screen modules is 3;

[0038]The surface of the screen is sprayed with a catalyst with a thickness of 0.5 μm to 20 μm;

[0039] The active ingredient of the catalyst is metal palladium particles;

[0040] The particle size of the catalyst component is 50-100nm;

[0041] The weight percentage of the active ingredients of the catalyst in the catalyst layer is 0.01wt% to 0.08wt%;

[0042] The carrier of the active component of the catalyst is α-Al 2 o 3 .

[0043] The support block 1 is welded on the middle inner wall 5 of the upper space of the packing bubble, and the three wire mesh modules are respectively fixed on the support block 1 by fasteners 2, which are Φ12 stainless steel stud bolts.

[0044] The packed bubbling bed gas demister provided by...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com