Temperature-controlled rolling equipment for production of metal plate in coils

A technology for temperature-controlled rolling and metal plate, applied in metal rolling, metal rolling, metal processing equipment, etc., can solve the problem of inaccurate temperature control, not considering the cooling of rolls and bearing seats, and difficult to uniformly control the surface temperature of rolls distribution, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

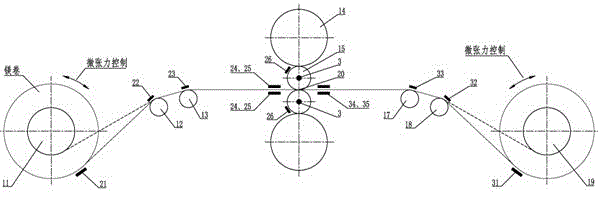

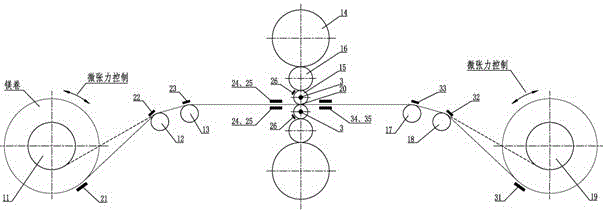

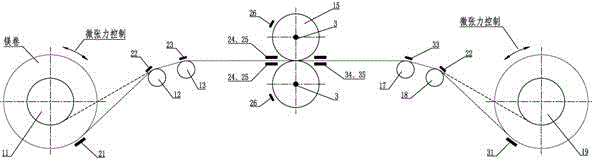

[0051] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0052] A temperature-controlled rolling equipment for producing metal coils, the temperature-controlled rolling equipment is a rolling mill, and the rolling mill is symmetrically arranged on the left and right, that is, the entrance side and the exit side are symmetrically arranged, and it includes: rolling mill back-up rolls 14, rolling mill work rolls 15, Roll surface heating device 26, roll core cooling and chock cooling mechanism 3, inlet side parts and outlet side parts, rolling mill back-up roll 14 supports rolling mill work roll 15, where the work roll 15 rolls the strip is the mill roll gap 20, Roll surface heating device 26 is installed on the roll surface of rolling mill work roll 15 , and roll core cooling and bearing seat cooling mechanism 3 are installed on the core and chock of rolling mill work roll 15 .

[0053] The entrance sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com