Patents

Literature

39results about How to "With anti-adhesion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

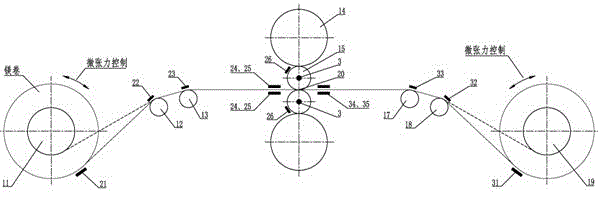

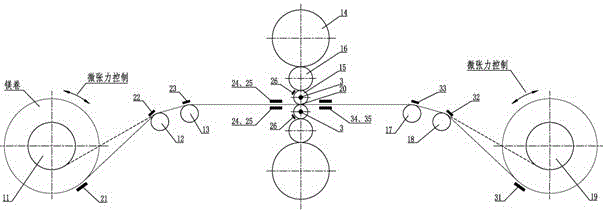

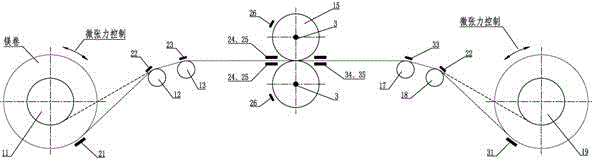

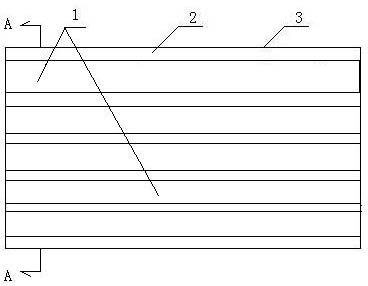

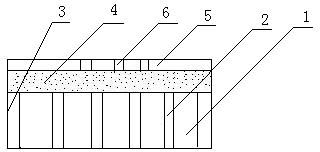

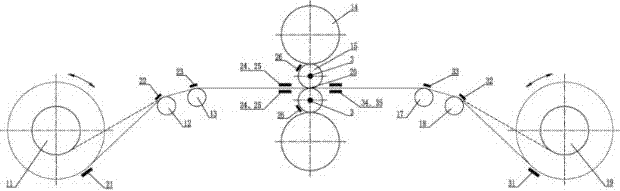

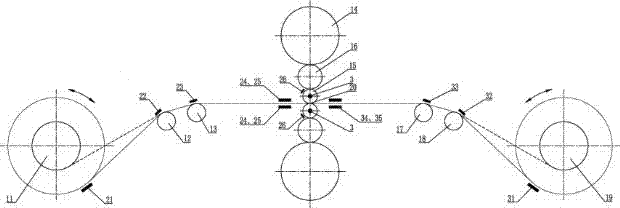

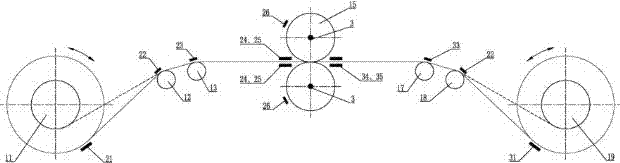

Temperature-controlled rolling equipment for production of metal plate in coils

ActiveCN105834214APrecise temperature controlDifferent mechanical propertiesTemperature control deviceRollsTemperature controlWork roll

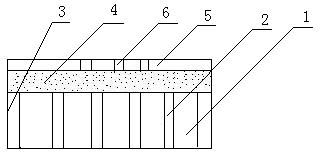

The invention relates to temperature-controlled rolling equipment for production of metal thin ribbons and ultra-thin strips in coils.The temperature-controlled rolling equipment is arranged in the bilaterally symmetrical mode. The position where a working roll (15) is used for rolling strips is a rolling mill gap (20). Inlet and outlet side parts comprise measuring tension rolls (13, 17), steering rolls (12, 18), and recoiling machines (11, 19). All parts are sequentially arrayed with the rolling mill gap as the center from the inside to the outside. The equipment further comprises an uncoiling and heating device (21), a plate strip heat-compensating device (24) and a plate strip edge heating device (25) before ingress of the rolling mill gap, a roll surface heating device (26), and a roll core cooling and bearing seat cooling mechanism (3), a plate strip edge heating device (35) and the plate strip heat-compensating device (34) after egress of the rolling mill gap, a pre-coiling heating device (31), heating devices (22, 32) at positions of the steering rolls and heating devices (23, 33) at positions of the measuring tension rolls at the inlet side.

Owner:BAOSHAN IRON & STEEL CO LTD

Production technology for polycrystalline silicon

The invention discloses a production technology for polycrystalline silicon. The production technology includes the following steps: 1, a first coating, a second coating and a third coating are sequentially arranged on the surface of a crucible from inside to outside, and a crystalline silicone leftover material layer is laid; 2, a small quantity of raw polycrystalline silicon materials in the melted state is contained in the crucible, and the temperature of the crucible is controlled to be lower than the melting point of the crystalline silicone leftover material layer to enable the small quantity of melted raw polycrystalline silicon materials to form a crystallization protection layer; 3, in the vacuum environment, to-be-processed raw polycrystalline silicon materials are contained in the crucible, placed in a melting furnace with an electron beam generating device and processed through laser irradiation; 4, high-frequency induction heating is carried out in the vacuum environment, a slag forming constituent is added, plasma heating is carried out, steam-and-hydrogen-mixed argon is introduced, and directional solidification is carried out to obtain the polycrystalline silicon serving as the target product. By means of the production technology, the boron content, the phosphorous content and the metal impurity content can be effectively reduced, the complete polycrystalline silicon is prepared, long crystal dislocation is less, grain boundaries are proper, and the conversion rate of a polycrystalline silicon battery is increased.

Owner:THE SIXTH CONSTR CO LTD OF CHINA NAT CHEM ENG

Bamboo alginate functional dressing and preparation method thereof

The invention belongs to the field of medical dressings, and particularly relates to a bamboo alginate functional dressing and a preparation method thereof. The dressing comprises the following components in parts by weight: 1-4.2 parts of sodium alginate, 0.05-0.4 part of sodium hyaluronate, 0.25-2 parts of collagen, 4.5-31 parts of bioactive glass powder and 62-95 parts of bamboo fiber. The dressing can quickly promote healing of a wound surface, and healed wound surface is smooth and resilient and is less prone to scar proliferation; and the dressing has the functional characteristics of antisepsis, imbibition, hemostasis, adhesion prevention, no cytotoxicity and the like, and can satisfy various requirements for wound surface healing. According to the preparation method of the bamboo alginate functional dressing, the problem that the alginate medical dressing is cracked after exudate imbibition is solved, thereby facilitating dressing change by medical personnel.

Owner:GUANGDONG TAIBAO MEDICAL SCI TECH

Procyanidine-modified carboxymethyl chitosan

The invention discloses procyanidine-modified carboxymethyl chitosan, a preparation method thereof, and application thereof in the fields of medical materials, health-care foods, cosmetics and the like. The procyanidine-modified carboxymethyl chitosan keeps the characteristics of carboxymethyl chitosan and has high oxidation resistance, antibacterial activity, barrier properties and the like, and is worthy of being applied.

Owner:SHIJIAZHUANG YISHENGTANG MEDICAL SUPPLIES

Starch compound polysaccharide hemostatic powder and preparation method thereof

InactiveCN104474571AGood water swelling performanceFast absorptionAbsorbent padsBandagesHEMOSTATIC POWDERIon exchange

The invention relates to starch compound polysaccharide hemostatic powder and a preparation method thereof. The preparation method comprises the following steps: carrying out enzymatic denaturation on starch to obtain a porous starch solution, dissolving sodium hyaluronate in deionized water to obtain a sodium hyaluronate solution, mixing the two solutions according to a weight ratio of 50-95 parts of porous starch solution to 5-50 parts of sodium hyaluronate solution, stirring uniformly and drying, soaking the dried material in a calcium chloride solution with a certain concentration to carry out ion exchange, and grinding the material into powder after secondary drying. The material provided by the invention has efficient stypticity on wound surfaces, is biodegradable, has the functions of anti-adhesion and moisture retention, and is safe and non-toxic, simple in preparation process and low in cost.

Owner:CHONGQING LIANBAI BOCHAO MEDICAL EQUIP

Formula of medical biocolloid solution and preparation method thereof

InactiveCN102755663AProtect t-PA activityReduce expressionAbsorbent padsBandagesPotassium nitrateGlycine

The invention discloses a formula of a medical biocolloid solution and a preparation method thereof. The medical biocolloid solution comprises the following components in percentage by weight: 0.1-2.5% of polyglucosamine sodium carboxylate, 0.6-0.9% of sodium chloride or 0.8-1.2% of potassium nitrate or 0.8-1.4% of sodium nitrate or 0.9-2.2% of glycine or 2.6-4.8% of mannitol, and the balance of water for injection. The preparation method comprises the following steps: (1) washing the polyglucosamine sodium carboxylate with ethanol by a percolation process to remove alcohol-soluble substances, baking at low temperature to remove ethanol residues, and dissolving in water for injection to obtain a solution (1) for later use; (2) directly dissolving the sodium chloride, or potassium nitrate, or sodium nitrate, or glycine or mannitol for regulating osmotic pressure in water for injection to obtain a solution (2) for later use; (3) mixing the solution (1) and the solution (2), and adding water for injection to full dose; and (4) carrying out preliminary filtration, fine filtration and sterile filling on the solution obtained in the step (3), thereby obtaining the medical biocolloid solution.

Owner:GUIZHOU YANGSHENG MEDICAL INSTR

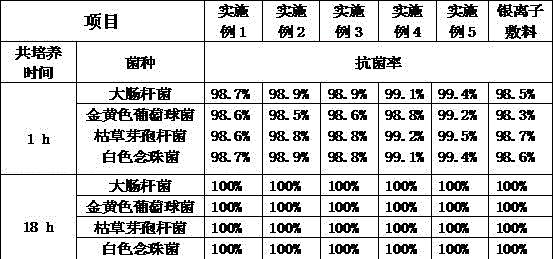

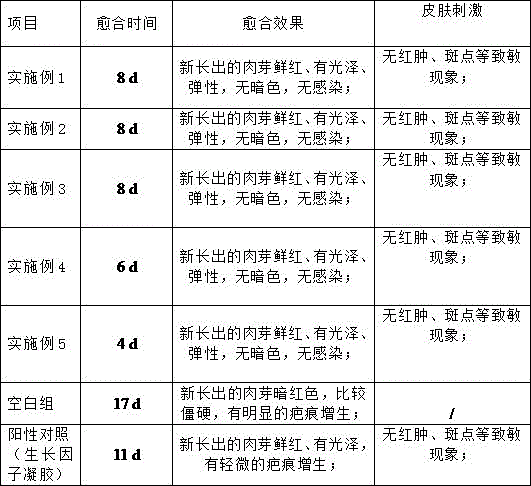

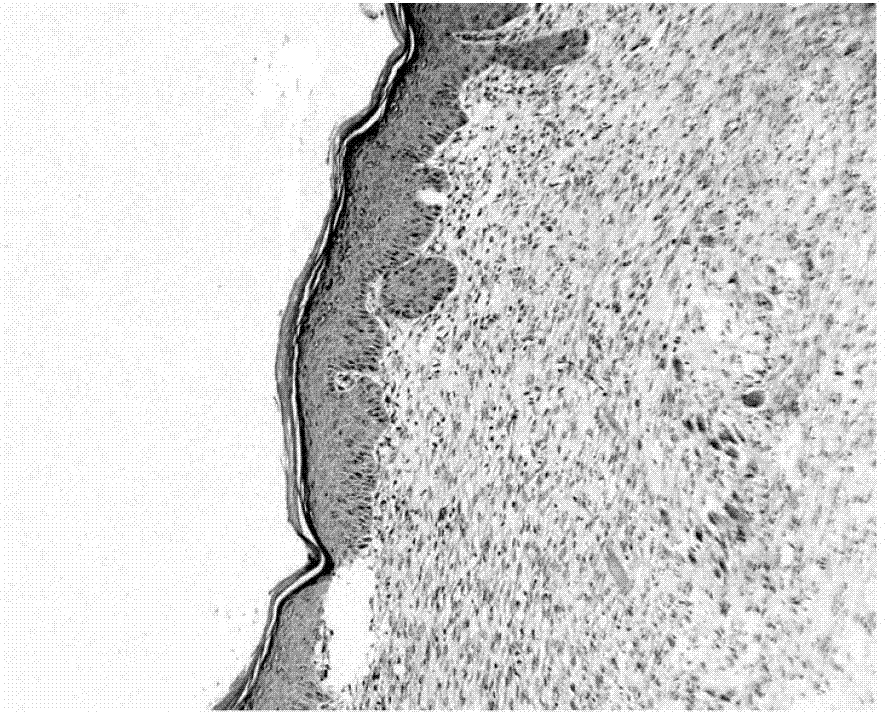

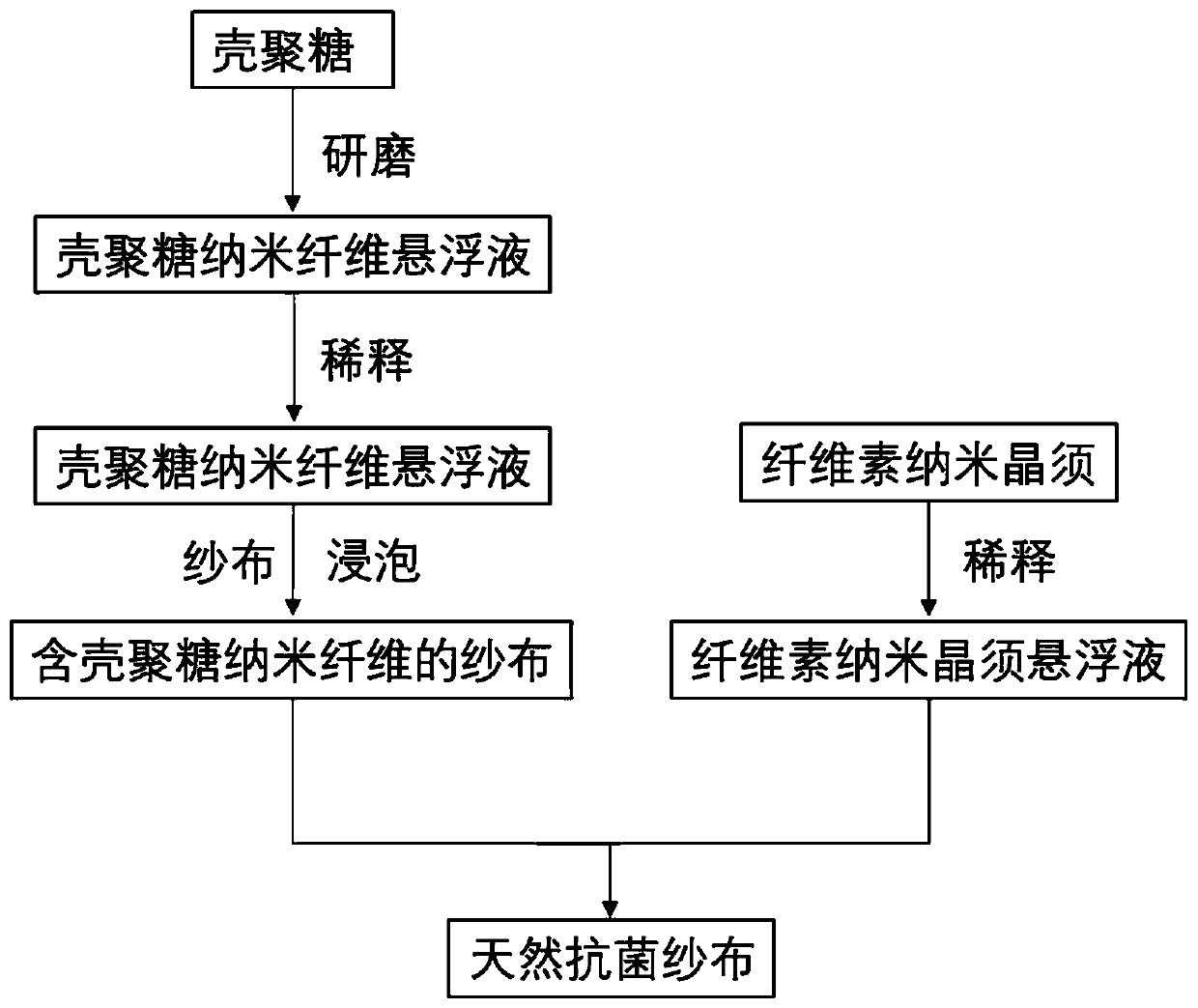

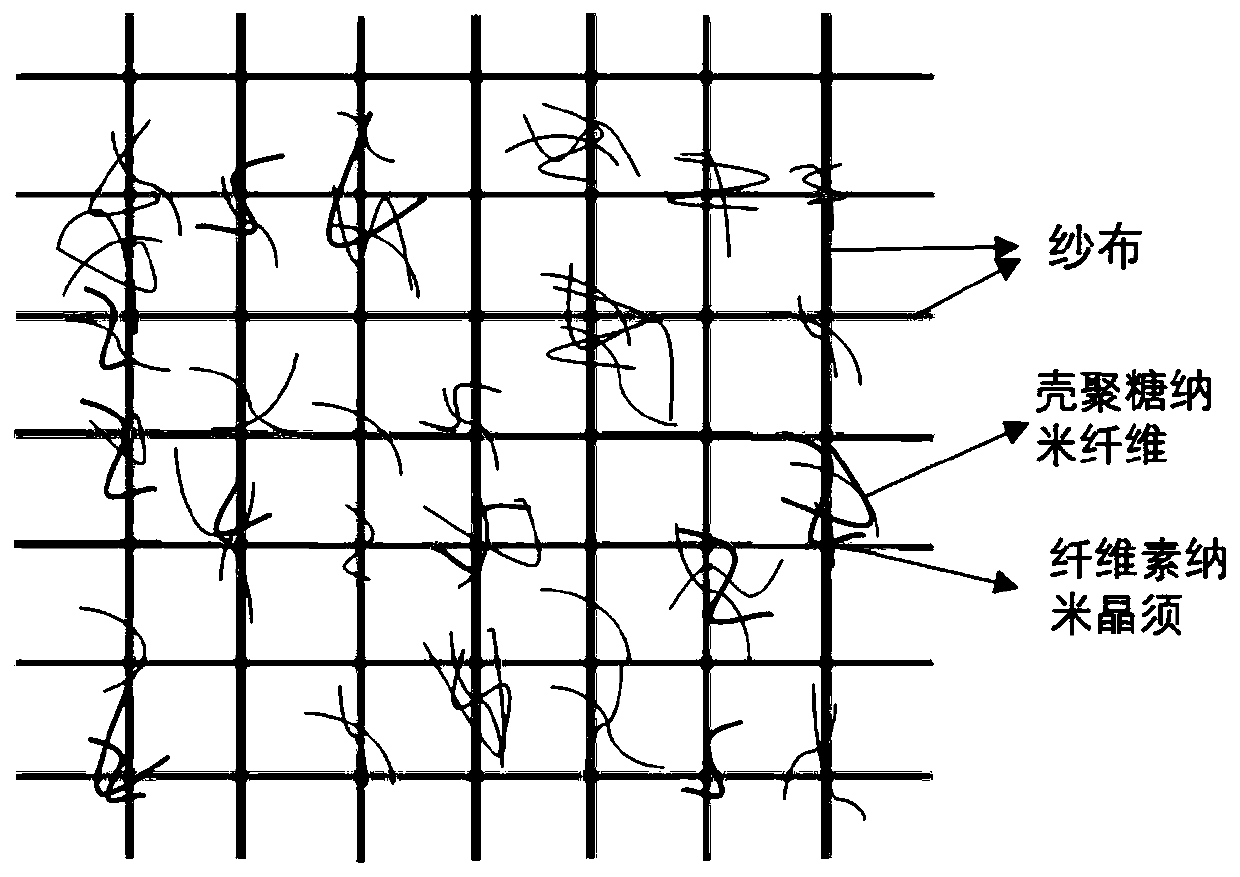

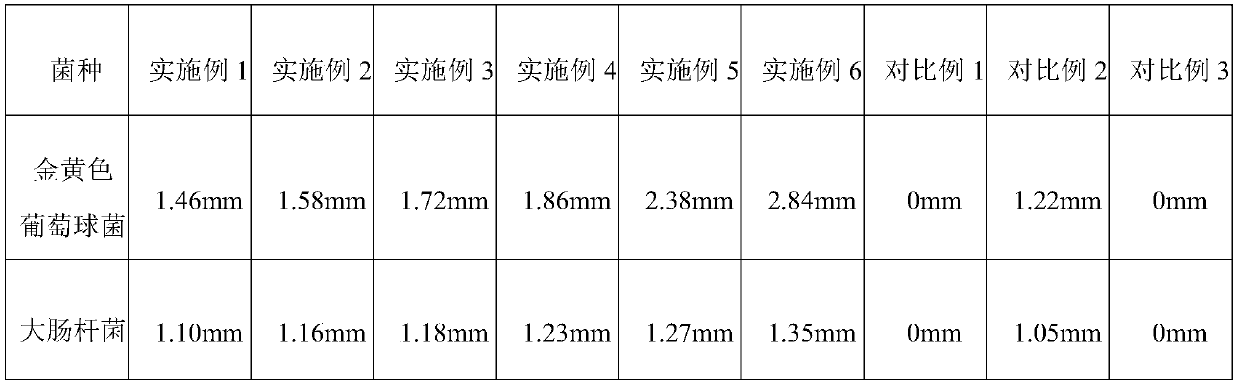

Natural antibacterial gauze and preparation method and application thereof

InactiveCN110522560ASimple preparation processSimple processAdhesive dressingsWound healingCellulose

The invention discloses natural antibacterial gauze and a preparation method and application thereof. The method comprises the following steps of (1) adding chitosan to water, performing uniform stirring and dispersing, then performing grinding, and adding water for diluting to obtain chitosan nanofiber suspension; (2) enabling cellulose nanometer crystal whiskers to disperse in water to obtain cellulose nanometer crystal whisker suspension; (3) soaking the gauze in the chitosan nanofiber suspension, performing taking out, and performing drying to obtain the gauze containing chitosan nanofibers; (4) immersing the gauze containing chitosan nanofibers in the cellulose nanometer crystal whisker suspension, performing taking out, and performing drying to obtain the gauze containing chitosan and cellulose nanometer crystal whiskers; and (5) ending the step (4), or repeating the steps (1) to (4) to obtain the natural antibacterial gauze. The obtained gauze can realize slow release of an antibacterial agent so as to prolong the antibacterial effectiveness, wound healing is facilitated, and the natural antibacterial gauze has anti blocking function and can be applied to the antibacterial field for medical care.

Owner:SOUTH CHINA UNIV OF TECH

Waterborne scratch-resistant anti-fog anti-dropping paint and application thereof

InactiveCN107266994AImprove scratch resistanceReduce coefficient of frictionPolyurea/polyurethane coatingsPolyvinyl alcoholMaterials science

The invention provides a waterborne scratch-resistant anti-fog anti-dropping paint. The paint comprises, by weight, 1 to 15% of a nanometer titanium sol, 1 to 5% of a nanometer aluminum sol, 0.1 to 10% of waterborne polyurethane, 0.1 to 10% of waterborne acrylic acid emulsion, 0.1 to 5% of a waterborne organosilicon scratch-resistant aid, 3 to 15% of vinyl acetate-ethylene copolymer emulsion, 1 to 12% of polyvinyl alcohol, 0.1 to 2% of a wetting agent, 1 to 10% of an emulsifier and 65 to 90% of deionized water, summing to 100%. The waterborne scratch-resistant anti-fog anti-dropping paint provided by the invention has the characteristics of obvious scratch resistance and good anti-fog and anti-dropping, is free of any organic solvent and has the advantages of no toxicity and environment friendliness; and after a greenhouse with a greenhouse film coated with the paint is used for two years, scratches on a coating of the greenhouse film are obviously reduced, and the anti-fog and anti-dropping performance of the greenhouse film is not obviously changed compared with the initial anti-fog and anti-dropping performance of the greenhouse film.

Owner:白山市喜丰塑业有限公司

Sustained drug release type medicine dressing

The invention discloses a sustained drug release type medicine dressing. Sodium alginate drug carrying capsules and a sodium alginate spinning solution are blended, spinning equipment and wet spinning are utilized for preparing alginate fibers carrying nano drug carrying capsules, a basic layer is composed of a protection layer and an absorption core layer, and a functional layer prepared from the alginate fibers carrying the nano drug carrying capsules and the basic layer are prepared into the sustained drug release type medicine dressing through spunlace processing. Hemostasis, bacterium resistance and adhesion prevention are achieved, the moisture preserving effect is good, the healing speed is high, and the sustained drug release type medicine dressing can be used for treating and protecting a variety of wounds.

Owner:泰安市飞虹麻丝制品科技有限公司

Antibacterial wear-resistant composite non-stick pan coating and preparation method thereof

ActiveCN112080204ADelay or hinder hydrolysis problemsExtended service lifeFireproof paintsCooking-vessel materialsCeramic coatingComposite ceramic

The invention discloses a preparation method of an antibacterial wear-resistant composite non-stick pan coating, and the method comprises the following steps: S1, carrying out sandblasting rougheningtreatment on a metal pan body, removing oil, and cleaning for later use; S2, uniformly ball-milling nano zinc powder, nano aluminum oxide powder and a dispersing aid, then uniformly mixing with a silane coupling agent and deionized water, then sequentially adding a zinc metal organic framework and the silane coupling agent, continuously performing stirring, uniformly coating the inner surface of the metal pot body with the mixture, and performing high-temperature calcination to obtain a non-stick pot bottom layer; S3, weighing a certain amount of silane modified nano silica sol; then adding anadditive and a suspending agent, performing stirring and mixing uniformly, coating a bottom layer with the mixture, and performing UV curing and drying in sequence to obtain the composite ceramic non-stick pan coating. The prepared non-stick pan ceramic coating solves the problems that an existing non-stick pan coating is poor in antibacterial property, prone to cracking, poor in abrasion resistance, short in service life and the like, and the long-term safe and healthy use requirement of the non-stick pan coating is met.

Owner:NINGBO TAIOOR COOKWARE

Prescription of light modified kynar

The invention discloses a prescription of light modified kynar, which comprises modified kynar, a brightener, an active agent, a foaming agent and a plasticizer. The brightener is modified amide wax, the active agent is hydrogen oxidation tetra-ethylamine, the foaming agent is azodicarbonamide, and the plasticizer is diisobutyl phthalate. The prepared light modified kynar has the advantages of adhesion resistance, smoothness, abrasion resistance and high plasticity.

Owner:SUZHOU NEW DISTRICT TEFLON PLASTIC PRODS FACTORY

Anti-infection wound-repairing pharmaceutical composition, preparation method and application thereof

InactiveCN112206281APromote growthEnlightenedAntibacterial agentsOrganic active ingredientsBiotechnologyBletilla striata

The invention discloses an anti-infection wound-repairing pharmaceutical composition in the technical field of biomedicines. The anti-infection wound-repairing pharmaceutical composition is prepared from the following raw materials in parts by weight, 30-40 parts of chitosan hydrochloride, 80-120 parts of cunninghamia lanceolata, 30-36 parts of bletilla striata, 2-8 parts of borneol and 450-550 parts of glycerol. The pharmaceutical composition is applied to prepare a film spraying preparation, and the preparation method comprises the following steps, step 1, weighing the raw materials in proportion, processing cunninghamia lanceolata and bletilla striata, and grinding the processed cunninghamia lanceolata and bletilla striata into fine powder; step 2, adding PVA1788 and chitosan hydrochloride to distilled water under water bath condition at 40 DEG C, and conducting magnetic stirring to be completely dissolved; step 3, adding cunninghamia lanceolata powder, bletilla striata powder and borneol, then adding glycerol, continuously conducting magnetic stirring to be completely dissolved, and standing at room temperature until foams are eliminated; step 4, adding absolute ethyl alcohol,conducting uniform stirring, standing for 5 minutes, and conducting bottling; and step 5, conducting sub-packaging and ultraviolet sterilization. The pharmaceutical composition disclosed by the invention has the effects of effusion resistance, adhesion prevention, hemostasis, anti-infection, promotion of wound healing, etc.

Owner:遵义医科大学珠海校区

Efficient photothermal conversion polycrystalline silicon plate and preparation method thereof

InactiveCN106191996AEasy to demouldWill not oxidizePolycrystalline material growthAfter-treatment detailsWater vaporMetal impurities

The invention discloses an efficient photothermal conversion polycrystalline silicon plate and a preparation method thereof. A first coating, a second coating and a third coating are sequentially arranged on the surface of a crucible from inside to outside, then an isolated layer of certain thickness is laid at the bottom of the crucible, and polycrystalline silicon raw materials are contained in the crucible; the crucible containing the polycrystalline silicon raw materials is placed in a melting furnace with an electron beam generating device to be treated, then a silicon solution is obtained, cooling, crushing, acid pickling and drying are carried out, and then a crystal growing stage is carried out; after the crystal growing stage is carried out, the temperature of a temperature control thermocouple and the rate of upward movement of a side heat insulation cage are regulated, meanwhile, water vapor and hydrogen doped argon is introduced, and directional solidification is carried out; after molten silicon is completely crystallized, annealing and cooling are carried out, and the efficient photothermal conversion polycrystalline silicon plate is formed. The process is easy to operate, scientific, reasonable and high in production efficiency, the content of boron, phosphorus and metal impurities in the polycrystalline silicon plate can be effectively reduced, complete polycrystalline silicon is prepared, little crystal growing dislocation is generated, the grain boundary is proper, and the photothermal conversion efficiency is improved.

Owner:TONGWEI SOLAR HEFEI

Formula of lubricating modified polyvinylidene fluoride

The invention discloses a formula of lubricating modified polyvinylidene fluoride. The lubricating modified polyvinylidene fluoride comprises modified polyvinylidene fluoride, a lubricating agent, a stabilizing agent, a plasticizing agent and a wear resisting agent, wherein the lubricating agent is polytetrafluoroethylene, the stabilizing agent is dibasic phosphite ester, the plasticizing agent is polyadipic acid propylidene ester, and the wear resisting agent is modified silicon-aluminum carbon black. According to the invention, the prepared lubricating modified polyvinylidene fluoride is anti-blocking, smooth, wear-resistant and high-plasticity.

Owner:SUZHOU NEW DISTRICT TEFLON PLASTIC PRODS FACTORY

Special protective glue for lubricating anti-sticking lip and application of special protective glue to tipping paper

The invention discloses special protective glue for lubricating an anti-sticking lip and application of the special protective glue to tipping paper, and aims to solve the problem that the tipping paper is stuck to the lip to cause lip sticking in the smoking process at present and bad smoking experience is brought to consumers. The special protective glue is prepared from the following raw materials in percentage by weight: 25 to 30 percent of polyvinyl butyral, 5 to 10 percent of fumed silica, 55 to 60 percent of edible ethanol, 6 to 9 percent of castor oil, 0.5 to 1.5 percent of micro wax powder and 0.05 to 0.5 percent of erucyl amide. The special protective glue has the advantages that the friction resistance and the hand feeling of the surface of the tipping paper product are obviously improved; the special protective glue has a very good smooth effect on the surface and is smooth, anti-adhesion, self-cleaning, hydrophobic, stain-resistant and scratch-resistant and does not influence the fastness and the adhesive force of a printing ink coating so that the lip of the smoker is protected, a certain lip protecting and moistening effect can be achieved and the lip and the fingersof the smoker are protected against injuries.

Owner:YUXI SIRUN PRINTING

A kind of preparation method of wear-resistant ceramic coating non-stick pan

ActiveCN112138967BHigh temperature resistantWith anti-adhesionCooking-vessel materialsPretreated surfacesUV curingCeramic coating

The invention discloses a preparation method of a non-stick pan with a wear-resistant ceramic coating, which comprises the following steps: step S1: performing sandblasting and roughening treatment on the metal pan body to form an uneven convex structure on the inner surface of the pan, and then performing Degreasing treatment and cleaning for later use; step S2: by weight, respectively weigh 45-65 parts of boron-modified silica sol and 30-50 parts of silane-modified nano-titanium sol; and add 10-15 parts of additives and 1.5 ~4.5 parts of suspending agent, stir and mix evenly to obtain coating slurry; step S3: coat the coating slurry obtained in step S2 on the inner surface of the pot in step S1, first use UV curing, and then quickly dry to obtain The wear-resistant ceramic coating is non-stick. The non-stick pan ceramic coating prepared by the invention not only has the characteristics of high-temperature boiling resistance and anti-sticking, but also has the advantages of anti-cracking, antibacterial and wear-resistant, and meets the long-term safe use requirements of the non-stick pan coating.

Owner:NINGBO TAIOOR COOKWARE

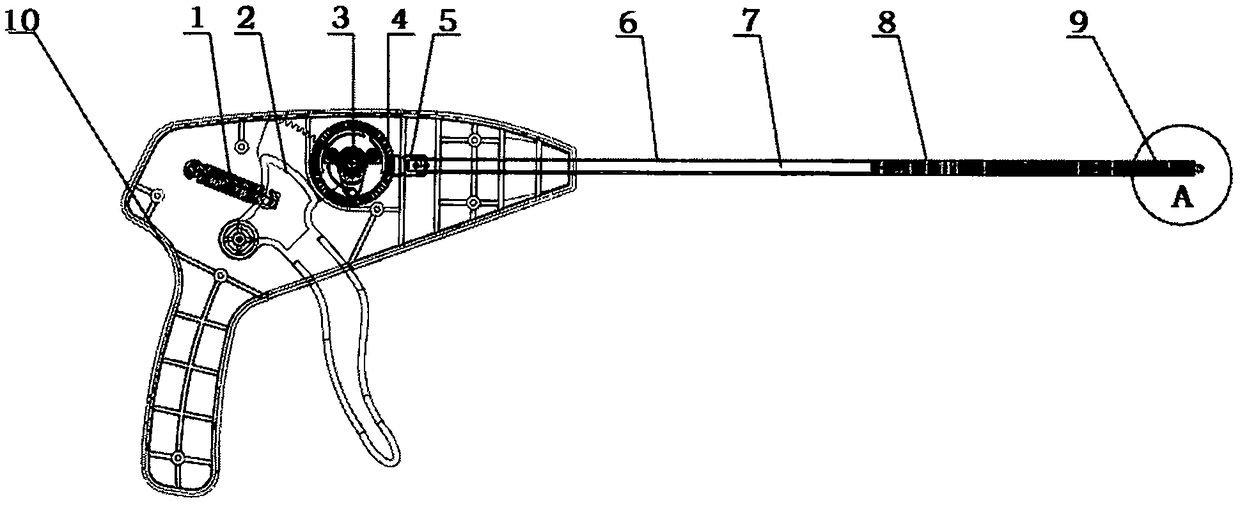

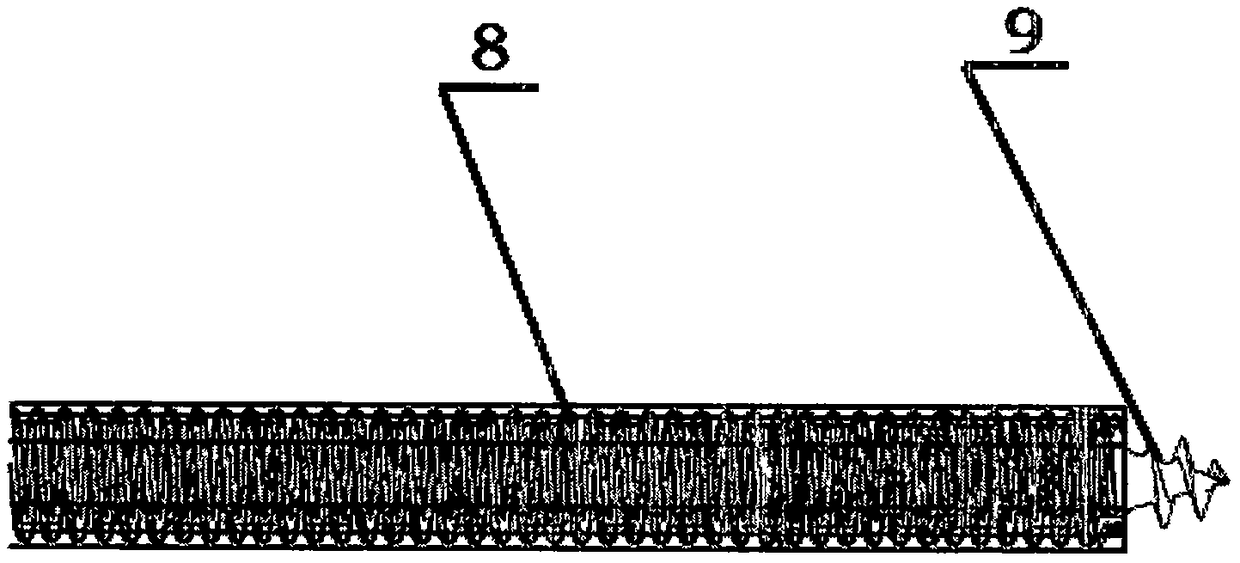

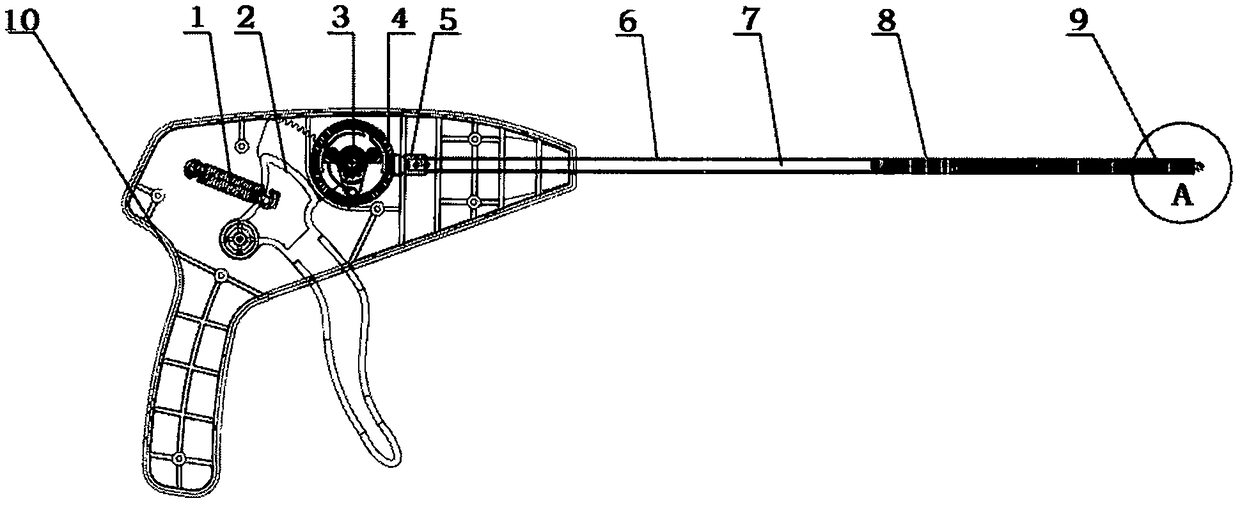

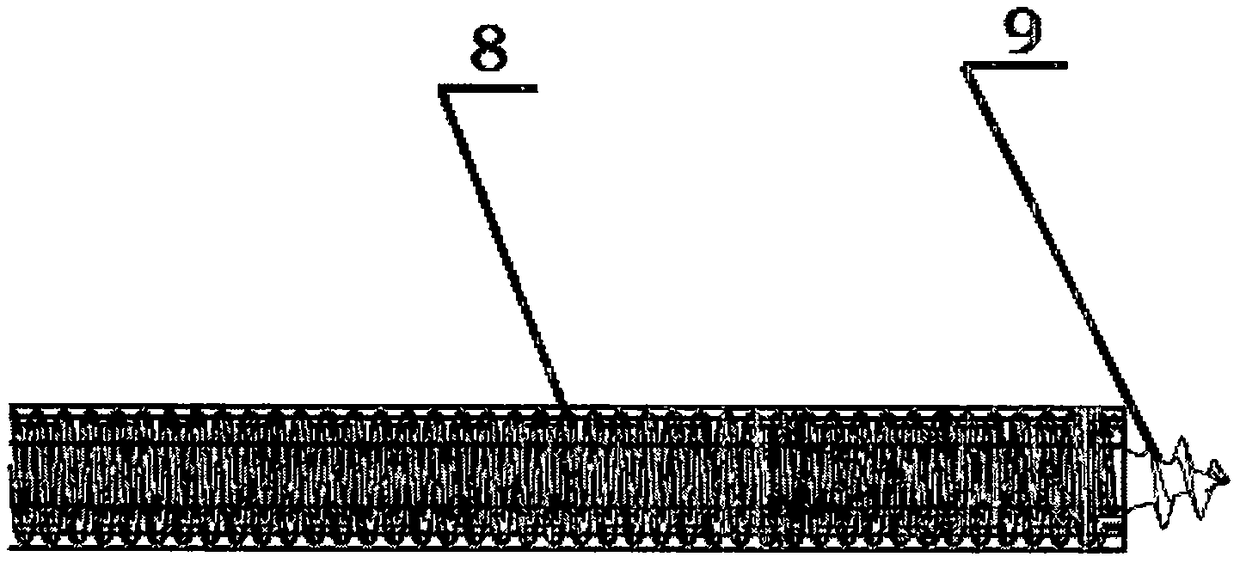

Absorbable staples and soft tissue fixation devices containing absorbable staples

ActiveCN105496482BModerate intensityGood degradation stabilityPharmaceutical delivery mechanismStaplesSodium saltGuide tube

Owner:TRANSEASY MEDICAL TECH

Antibacterial and wear-resistant composite non-stick pan coating and preparation method thereof

ActiveCN112080204BImprove antibacterial propertiesImprove bindingFireproof paintsCooking-vessel materialsCeramic coatingComposite ceramic

The invention discloses a preparation method of an antibacterial and wear-resistant composite non-stick pan coating, which comprises the following steps: S1: performing sandblasting and roughening treatment on the metal pan body, and then degreasing and cleaning for standby; S2: applying nano-zinc powder , Nano-alumina powder and dispersing aid are evenly ball-milled, then evenly mixed with silane coupling agent and deionized water, then sequentially add zinc metal organic framework and silane coupling agent, continue to stir, and evenly coat on the inner surface of the metal pot , after high-temperature calcination, the non-stick pan bottom layer is obtained; S3: Weigh a certain amount of silane-modified nano-silica sol; then add additives and suspending agents, stir and mix evenly, and then apply it on the bottom layer, and then perform UV curing and drying successively. Get a composite ceramic nonstick coating. The non-stick pan ceramic coating prepared by the invention solves the problems of poor antibacterial performance, easy cracking, poor wear resistance and short service life of the existing non-stick pan coating, and meets the long-term safe and healthy use requirements of the non-stick pan coating .

Owner:NINGBO TAIOOR COOKWARE

Fresh medlar package box

InactiveCN102424209AHas ecological space requirementsRealize long-distance transportationLiving organism packagingClosuresEngineeringSpace requirements

The invention relates to a fresh medlar package box, which belongs to the field of package boxes and is provided with a box upper, wherein a box cover is covered on the box upper. The fresh medlar package box is characterized in that a box body is arranged in the box upper, a long groove is distributed on the box body, a sponge carrier is covered above the long groove, and vent holes are processed on the box cover. The fresh medlar package box has the advantages that the structure is simple, the ecological space requirements required after the fresh fruit picking are provided, the functions of corrosion prevention, fresh keeping, extrusion and pressing prevention, adhesion prevention, ventilation, shock prevention, transportation convenience and the like are realized, the long-distance transportation, storage and market sale of soft fresh fruits can be realized.

Owner:戴振东

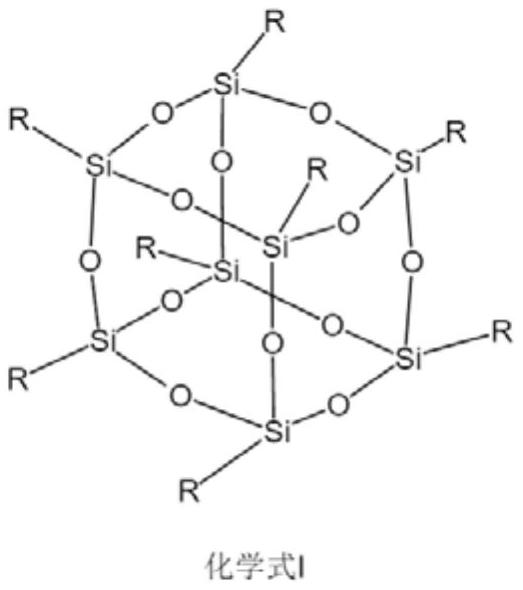

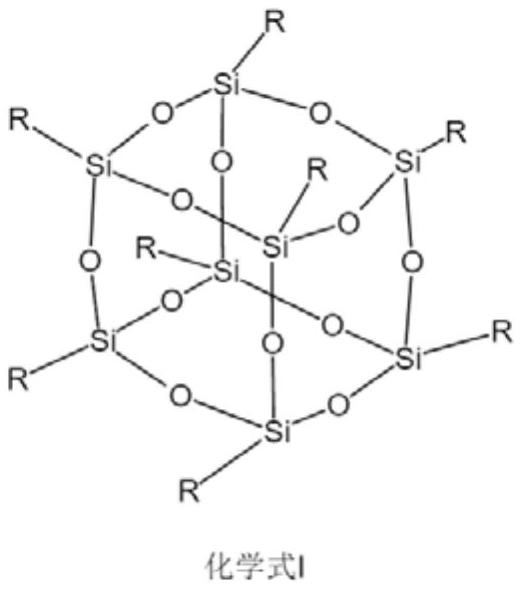

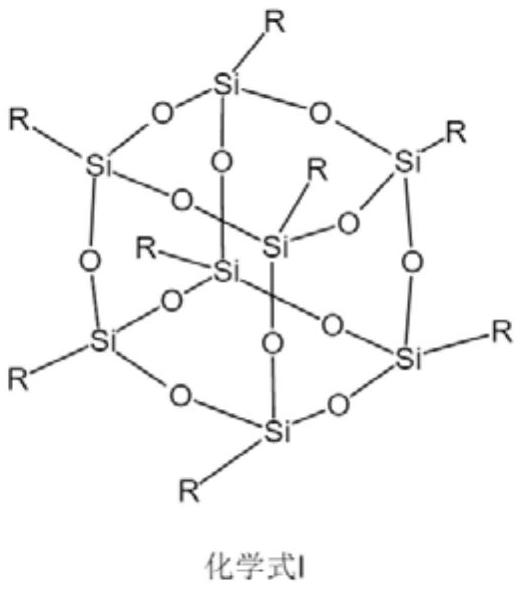

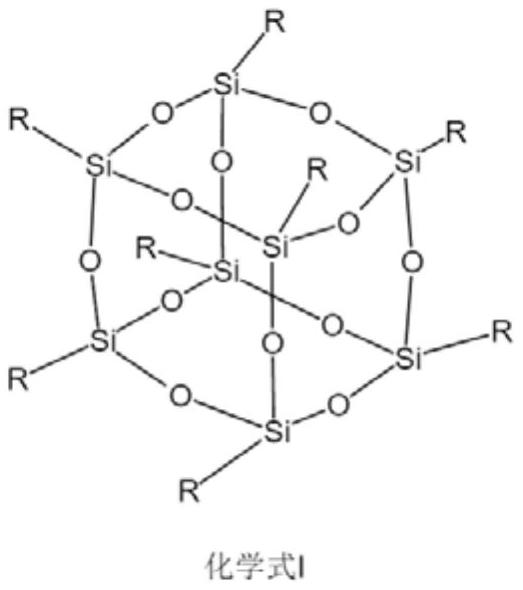

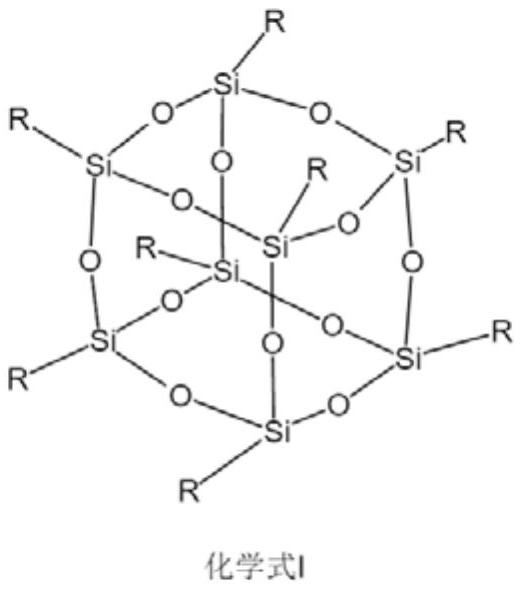

A kind of preparation method of sprayable transparent superamphiphobic coating

ActiveCN108047773BSuperhydrophobicSuper oleophobicAntifouling/underwater paintsPaints with biocidesFluid phaseDouble coating

Belonging to the paint field, the invention in particular relates to a preparation method of a sprayable transparent super-amphiphobic paint. The method includes the steps of: A. calcining 0.1-10g ofa silicon source under a 400-1200DEG C temperature condition for 2-6h to obtain a silica aggregate; B. modifying the silica aggregate obtained in step A by vapor deposition or liquid-phase condensation, and then performing drying to obtain a silica aggregate; and C. adding a solvent into the silica aggregate obtained by drying after modification in step B so as to obtain a suspension solution witha mass concentration of 1-100mg / mL, i.e. the product. The preparation method provided by the invention is simple, and the obtained super-amphiphobic paint has super-hydrophobicity, super-oleophobicity, oil stain resistance, adhesion prevention, and corrosion protection properties, and at the same time has high transparency, friction resistance, green and environmental protection and other excellent properties.

Owner:重庆前沿新材料技术研究院有限公司

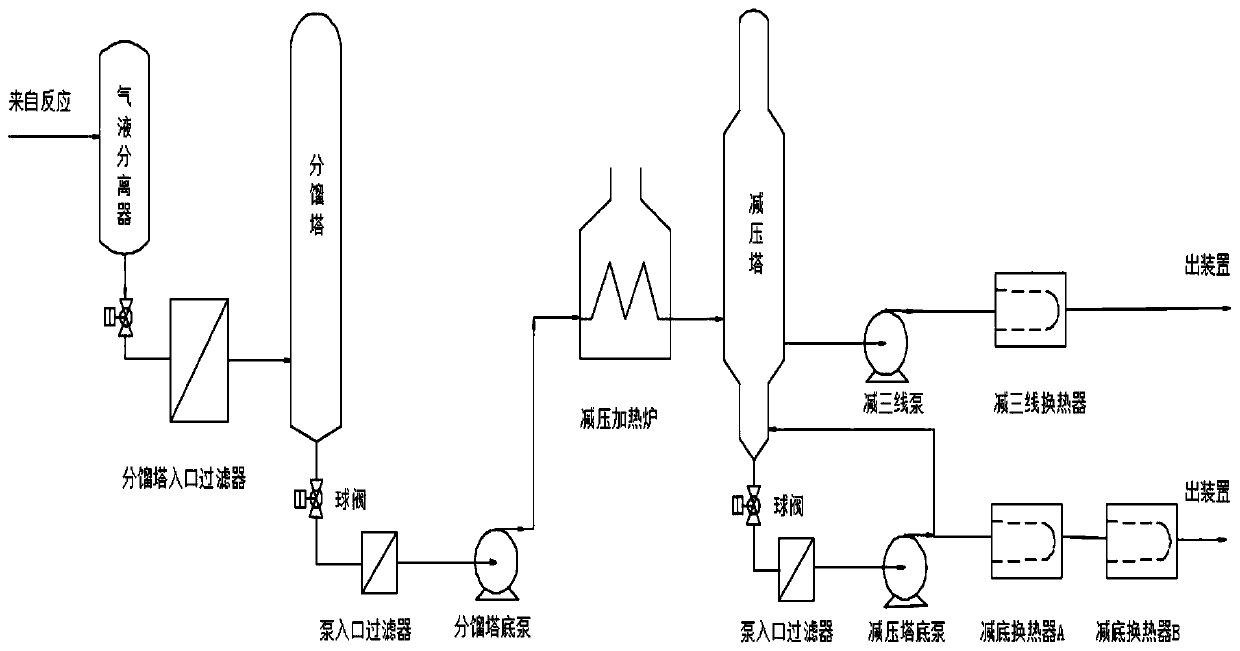

Method for solving problem of asphaltene coking in residual oil

PendingCN110732475AAvoid stickinessAvoid cokingPretreated surfacesCoatingsThermodynamicsCeramic coating

The invention discloses a method for solving the problem of asphaltene coking in residual oil and relates to the technical field of equipment decoking. A coating is sprayed to a device and a pipelinewhich are easy to coke. The coating is a high-temperature-resistant anti-sticking nano composite ceramic coating and has the characteristics of being resistant to high temperature, capable of preventing asphaltene sticking, resistant to wear and resistant to corrode, so that the sticking of asphaltene in the residual oil to the equipment and the pipeline is avoided. Compared with other anti-cokingmethods, for example, device equipment is filled with a chemical agent and a scale inhibitor, or the coked equipment is cleaned, by the adoption of the method, the effect of preventing coking of thedevice is more remarkable, the operation is convenient, safety and environment protection are achieved, and the labor amount is saved, so that the device can operate for a long period, and great economic benefits are brought to enterprises.

Owner:刘鹏 +3

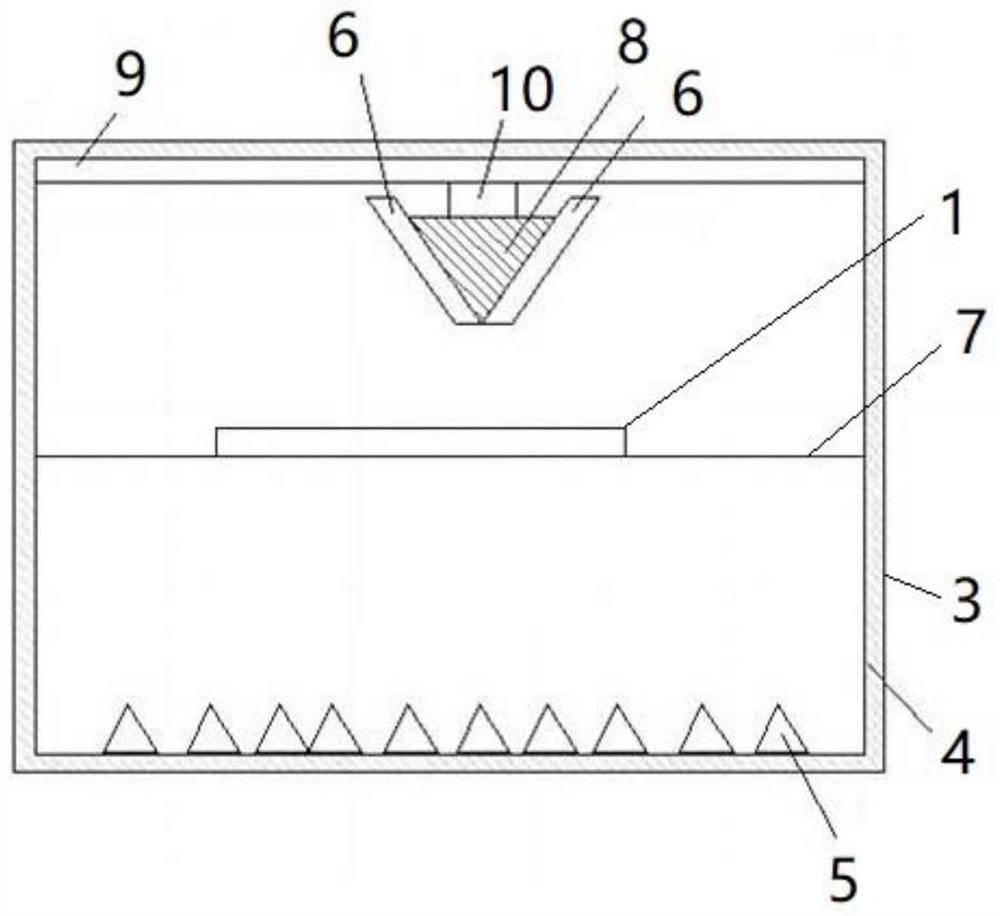

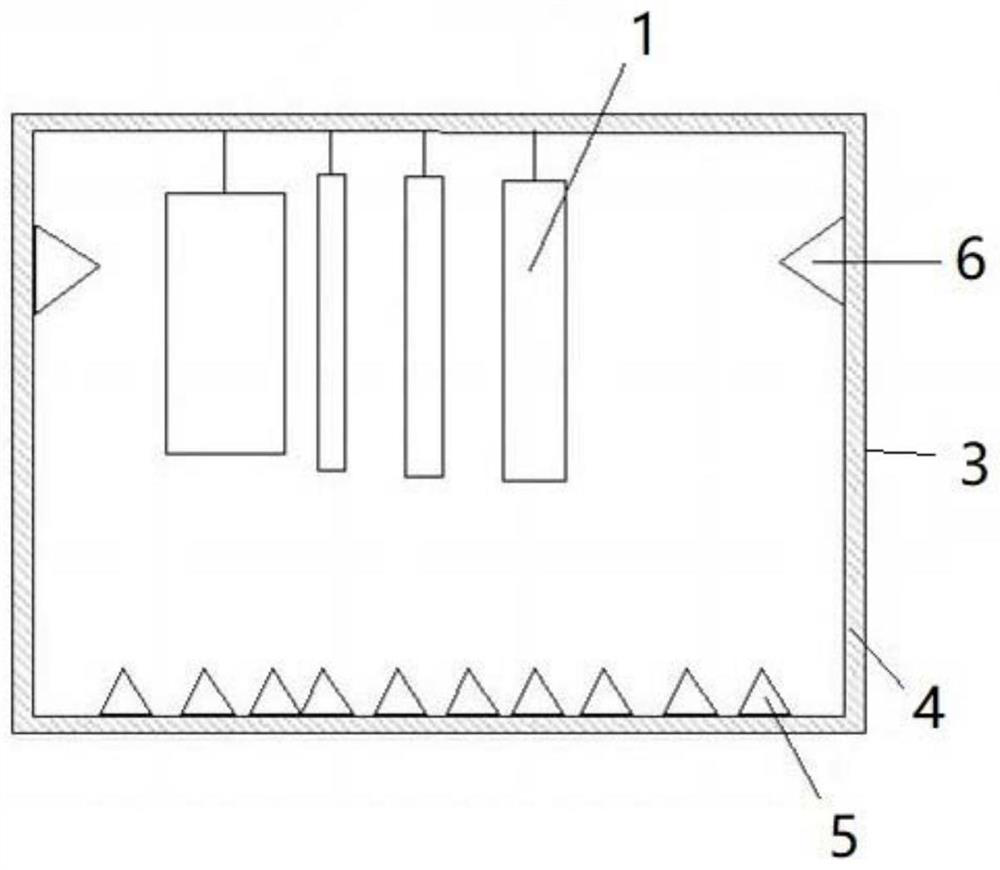

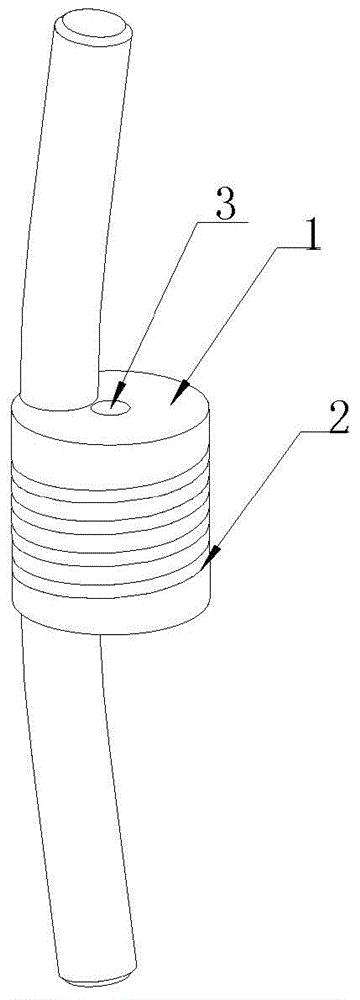

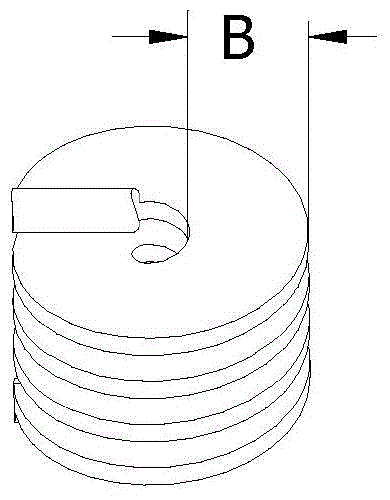

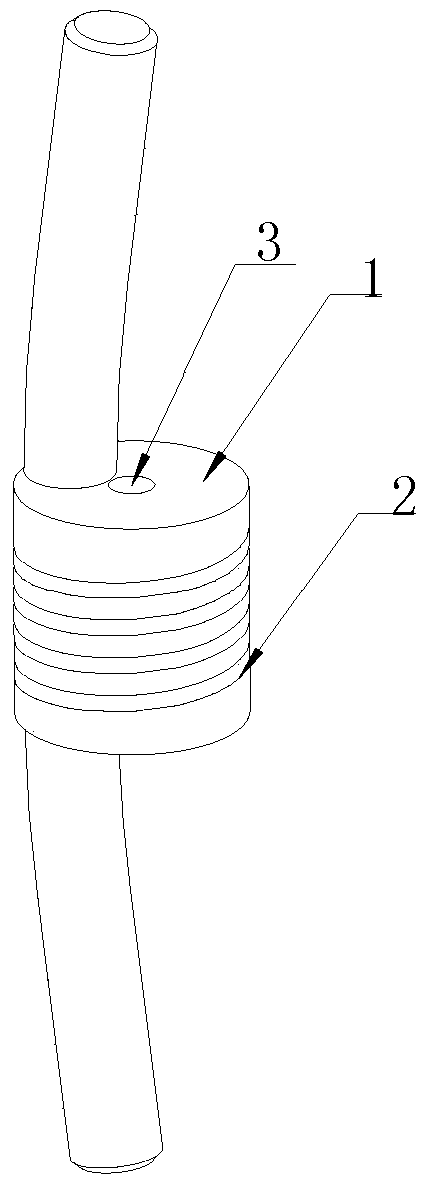

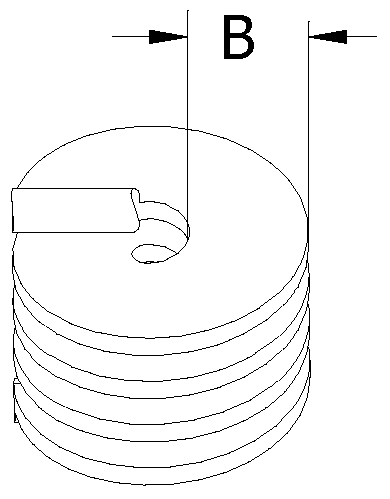

Soft tissue fixation device containing absorbable staples

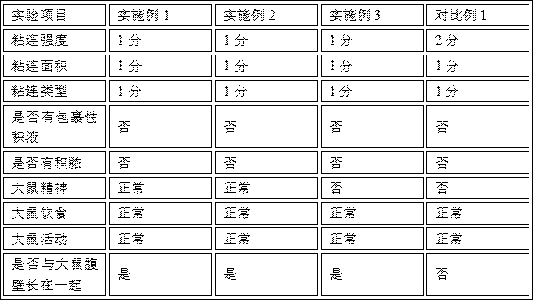

ActiveCN105596044BWith anti-adhesionEasy to operatePharmaceutical delivery mechanismStaplesCatheterScrew thread

The invention relates to a soft tissue fixing device with absorbable screws and belongs to the technical field of medical apparatus and instruments. The soft tissue fixing device with the absorbable screws comprises a driving device, a screw pipe and a driving rod, wherein the screw pipe is externally in screw joint with a guide pipe; the guide pipe is internally provided with multiple absorbable screws; thread structures are formed on nailed beams of the absorbable screws and provided with screw lead springs; the multiple absorbable screws are sequentially and serially connected end to end so as to be arranged in the guide pipe with a spiral groove. When in use, a trigger is pulled, so that the driving rod is driven by the driving device to rotate, and furthermore the absorbable screws can be emitted out from the guide pipe one by one during herniorrhaphy under a laparoscope. The soft tissue fixing device with the absorbable screws is especially applicable to the herniorrhaphy under the laparoscope, and has the characteristics of adhesion prevention, and convenience and reliability in operation; the guide pipe is a detachable replacement part, so that the fixing device can be repeatedly used only by replacing the guide pipe.

Owner:TRANSEASY MEDICAL TECH

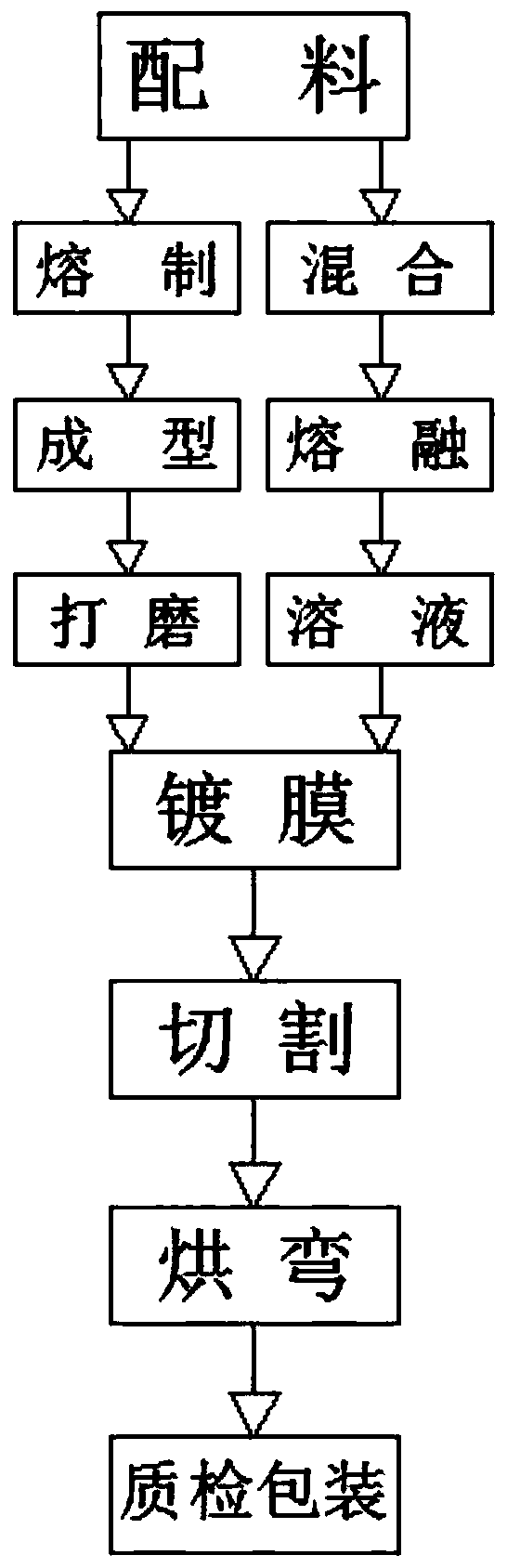

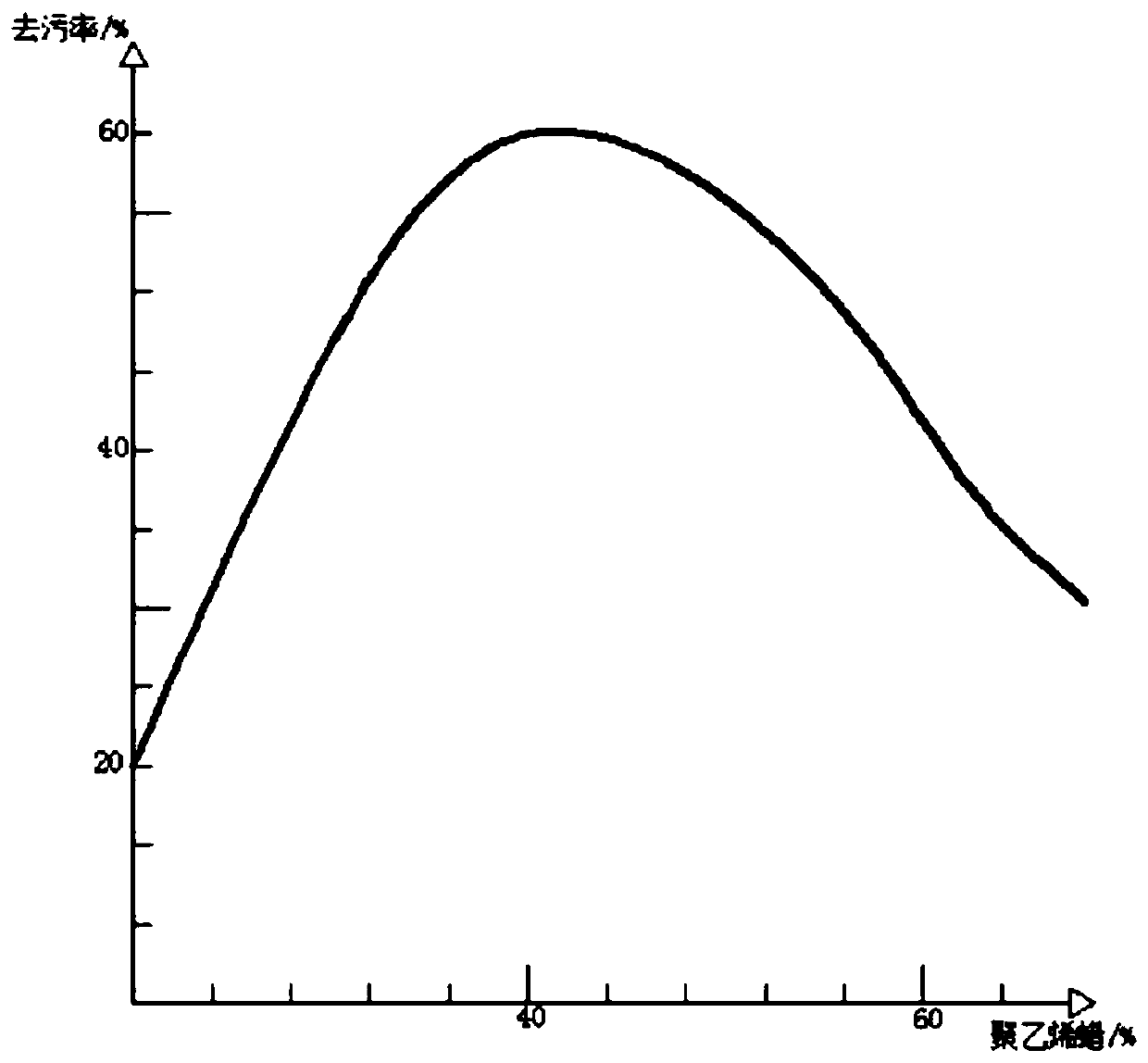

Automobile glass capable of preventing water stains from caking and preparation method thereof

The invention discloses automobile glass capable of preventing water stains from caking and a preparation method thereof. The preparation method comprises the following steps of burdening: firstly preparing raw materials of quartz sand, limestone, feldspar, soda ash and boric acid of the glass, and then preparing raw materials of nano silicon dioxide, nano titanium dioxide, nano zinc dioxide and polyethylene wax of a decontamination film; melting: heating the prepared raw materials at high temperature to form uniform bubble-free molten glass; and mixing: mixing the prepared nano silicon dioxide, nano titanium dioxide, nano zinc dioxide and polyethylene wax according to a ratio of 2: 2: 2: 4 to obtain a mixed solution, molding, injecting the molten glass into a mold, molding, and performingcooling to obtain raw material glass. According to the automobile glass, the decontamination film is plated on an automobile glass body, the polyethylene wax is added into the decontamination film, and the polyethylene wax has the effects of extinction, scratch resistance, wear resistance, polishing resistance, engraving resistance, adhesion resistance, precipitation resistance, thixotropy and the like, so that water stains on the glass can be effectively prevented from being condensed.

Owner:杨国秀

Oil gauze and preparation method

PendingCN112169009AReduce economic pressureEasy to prepareAbsorbent padsBandagesBiotechnologyWound healing

The invention provides oil gauze and a preparation method thereof, solves the problems that common gauze is adhered to a wound and does not have the effects of sterilizing, resisting infection and promoting wound healing, and is prepared from, by volume, 25% of white beeswax, 55% of peanut oil, 1% of honey and 19% of decoction containing 6% of cortex phellodendri, 5% of coptis chinensis, 4% of rheum officinale and 4% of radix scutellariae.

Owner:茂名市人民医院

Internal fracture fixation device

PendingCN112807494AHigh strengthCorrosion resistanceCoatingsFastenersTitanium metalInternal fixation

The invention provides an internal fracture fixation device. The internal fracture fixation device comprises a fixing plate; a titanium alloy steel plate is adopted as the fixing plate; and a peek coating is sprayed on the surface of the titanium alloy steel plate. The internal fracture fixation device mainly enhances advantages and avoids disadvantages of the characteristics of titanium metal and peek materials, has the effects of good strength, corrosion resistance and adhesion prevention, can completely eradicate pain caused by adhesion, enables extraction to be smoother in a secondary operation, and reduces tissue damage.

Owner:杨冠英

Spinal implantation unit and preparation method thereof

ActiveCN104586484AChemically stableImprove permeabilityInternal osteosythesisEccentric hypertrophyRoom temperature

Disclosed is a spine implant unit, comprising an elastic segment, wherein the elastic segment contains a silicone rubber loaded with a drug. Also disclosed is a method for preparing a spine implant unit, comprising the following operation steps: providing a spine implant unit, wherein the spine implant unit comprises an elastic segment; washing and drying the spine implant unit; and injecting liquid silicone rubber containing a drug and a curing agent into the elastic segment, curing at room temperature and forming a silicone rubber loaded with the drug. The spine implant unit has the following functions: relieving pain persistent ailment caused by adhesion and oppression of a focal point, clearing cartilage calcification to break down and absorb same and clearing edema and hypertrophy of yellow ligament and posterior longitudinal ligament.

Owner:SUZHOU MINIMALLY INVASIVE SPINAL TRAUMA MEDICAL TECH CO LTD

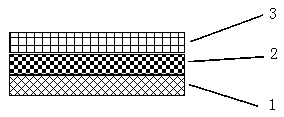

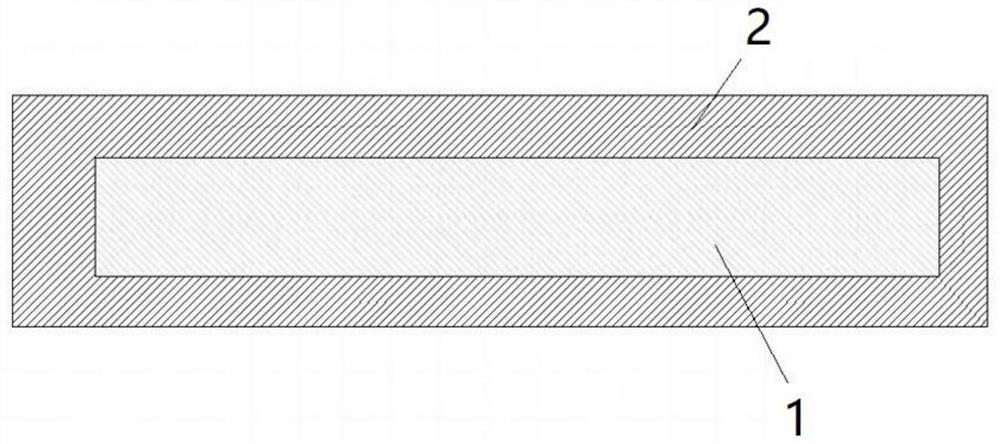

Double-layer anti-adhesion polypropylene patch, and preparation method and application thereof

The invention discloses a double-layer anti-adhesion polypropylene patch and a preparation method and application thereof, the double-layer anti-adhesion polypropylene patch comprises a polypropylenemonofilament layer and a polypropylene / polydopamine composite monofilament layer, wherein the polypropylene monofilament layer is knitted by a double-comb warp knitting process, and the polypropylene / polydopamine composite monofilament layer is knitted by a three-comb warp knitting process. The double-layer anti-adhesion polypropylene patch provided by the invention has the advantages of unilateral anti-adhesion, good biocompatibility and infection resistance, can be placed in the peritoneal cavity, can be used as a medical material for repairing abdominal external hernia, and remarkably reduces the incidence of complications such as intestinal adhesion, intestinal obstruction, intestinal fistula and infection.

Owner:SUN YAT SEN UNIV

A kind of spinal implant unit and its preparation method

ActiveCN104586484BWith anti-adhesionRelief the painInternal osteosythesisEccentric hypertrophySpinal column

Disclosed is a spine implant unit, comprising an elastic segment, wherein the elastic segment contains a silicone rubber loaded with a drug. Also disclosed is a method for preparing a spine implant unit, comprising the following operation steps: providing a spine implant unit, wherein the spine implant unit comprises an elastic segment; washing and drying the spine implant unit; and injecting liquid silicone rubber containing a drug and a curing agent into the elastic segment, curing at room temperature and forming a silicone rubber loaded with the drug. The spine implant unit has the following functions: relieving pain persistent ailment caused by adhesion and oppression of a focal point, clearing cartilage calcification to break down and absorb same and clearing edema and hypertrophy of yellow ligament and posterior longitudinal ligament.

Owner:SUZHOU MINIMALLY INVASIVE SPINAL TRAUMA MEDICAL TECH CO LTD

Temperature-controlled rolling equipment for the production of sheet metal coils

ActiveCN105834214BPrecise temperature controlDifferent mechanical propertiesTemperature control deviceRollsWinding machineTemperature control

The invention relates to a temperature-controlled rolling production equipment for coiled metal thin strips and ultra-thin strips. A temperature-controlled rolling equipment for producing metal coils is symmetrically arranged left and right, where the work roll (15) rolls the strip is the mill roll gap (20), and the entrance and exit side components include: tension measuring rolls (13, 17 ), steering rolls (12, 18), coilers (11, 19), and each component is arranged in order from the inside to the outside with the rolling mill roll gap as the center; the equipment also includes: uncoiling heating device (21), rolling mill roll gap Front strip heating device (24) and strip edge heating device (25), roll surface heating device (26), roll core cooling and bearing seat cooling mechanism (3), strip edge after exiting the roll gap Heating device (35) and strip heating device (34), heating device before coiling (31), heating device at turning roll (22, 32) and heating device at entrance-side tensioning roll (23, 33) .

Owner:BAOSHAN IRON & STEEL CO LTD

A special protective glue for lubricating and anti-adhesive lips and its application on tipping paper

ActiveCN111395035BPlay a protective effectNot traumatizedPaper coatingInksPolymer sciencePolyvinyl alcohol

The invention discloses a special protective glue for lubricating and anti-adhesive lips and its application on tipping paper. At present, during the smoking process, the tipping paper will stick to the lips and cause lip sticking, which will bring bad consequences to consumers. Tasting experience. It is prepared from the following raw materials by weight percentage: polyvinyl butyral 25-30%, fumed white carbon black 5-10%, edible ethanol 55-60%, castor oil 6-9%, micro wax powder 0.5- 1.5%, erucamide 0.05-0.5%. This application can significantly improve the friction resistance and hand feeling of the surface of tipping paper products; it has a very good smooth effect on the surface, smooth, anti-adhesion, self-cleaning, hydrophobicity, stain resistance, and abrasion resistance, and does not affect printing ink The fastness and adhesion of the coating; thus it can protect the lips of the smoker, and can protect the lips and lips of the smoker from trauma.

Owner:YUXI SIRUN PRINTING

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com