Antibacterial wear-resistant composite non-stick pan coating and preparation method thereof

A non-stick pan and coating technology, applied in coatings, fireproof coatings, anti-fouling/underwater coatings, etc., can solve the problems of short service life, poor wear resistance, poor antibacterial performance, etc., to improve service life, The effect of dense coating and high temperature resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

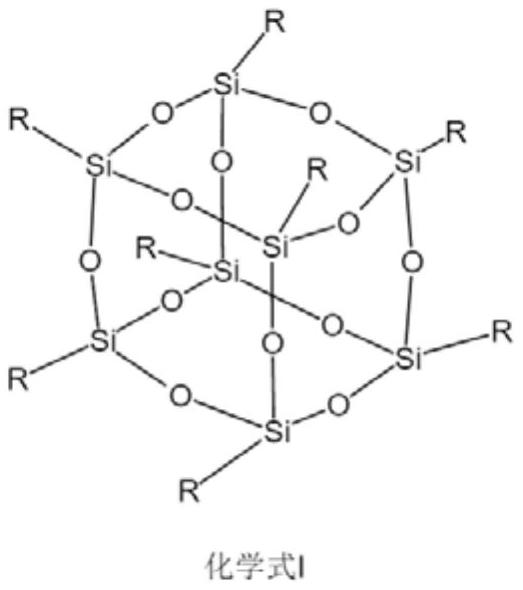

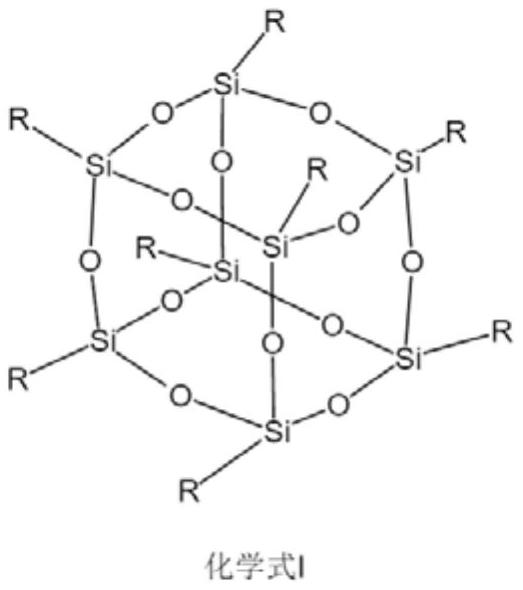

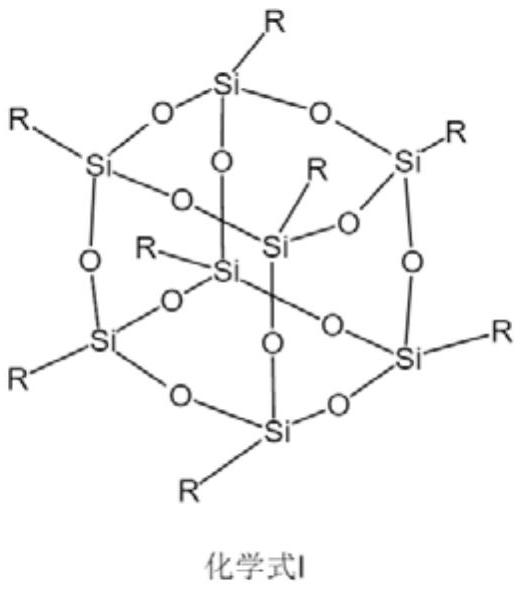

Method used

Image

Examples

Embodiment 1

[0029] The preparation method of the antibacterial and wear-resistant composite non-stick coating of the present embodiment comprises the following steps:

[0030] Step S1: Put the metal pot body into the sand blasting machine, use silicon carbide ceramics as shot blasting, and perform sand blasting roughening treatment to form an uneven convex structure on the inner surface of the pot body, then degrease and clean it spare;

[0031] Step S2: In parts by weight, weigh 5 parts of nano-zinc powder, 10 parts of nano-alumina powder, 3 parts of ethanol and 0.5 part of polyethylene glycol, ball mill in a high-speed ball mill for 12 hours, sieve with a 300-mesh screen, and take Mix 20 parts of undersize with 1.5 parts of vinyltriethoxysilane and 35 parts of deionized water, then add 16 parts of zinc metal-organic framework and 1.5 parts of vinyltriethoxysilane in sequence, and continue to stir for 30 minutes. Coating on the internal surface of the metal pot in step S1, sending it in...

Embodiment 2

[0040] The preparation method of the antibacterial and wear-resistant composite non-stick coating of the present embodiment comprises the following steps:

[0041] Step S1: Put the metal pot body into the sand blasting machine, use silicon carbide ceramics as shot blasting, and perform sand blasting roughening treatment to form an uneven convex structure on the inner surface of the pot body, then degrease and clean it spare;

[0042] Step S2: In parts by weight, weigh 7 parts of nano-zinc powder, 14 parts of nano-alumina powder, 4 parts of ethanol and 1 part of polyvinyl alcohol, ball mill in a high-speed ball mill for 12 hours, sieve with a 400-mesh screen, and take 25 parts 2.5 parts of vinyltrimethoxysilane and 45 parts of deionized water were uniformly mixed with 2.5 parts of vinyltrimethoxysilane, and then 28 parts of zinc metal organic framework and 2.5 parts of vinyltrimethoxysilane were added in sequence. After stirring for 60 minutes, evenly coated on On the inner su...

Embodiment 3

[0051] The preparation method of the antibacterial and wear-resistant composite non-stick coating of the present embodiment comprises the following steps:

[0052] Step S1: Put the metal pot body into the sand blasting machine, use silicon carbide ceramics as shot blasting, and perform sand blasting roughening treatment to form an uneven convex structure on the inner surface of the pot body, then degrease and clean it spare;

[0053] Step S2: In parts by weight, weigh 10 parts of nano-zinc powder, 18 parts of nano-alumina powder and 6 parts of ethanol, and after ball milling in a high-speed ball mill for 12 hours, sieve with a 500-mesh screen, take 30 parts of undersieve and 3.5 parts of Parts of vinyl tris(β-methoxyethoxy)silane and 55 parts of deionized water were uniformly mixed, then 42 parts of zinc metal organic framework and 3.5 parts of vinyl tris(β-methoxyethoxy)silane were added in sequence, and continued After stirring for 90 minutes, evenly coat the inner surface ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com