A kind of preparation method of wear-resistant ceramic coating non-stick pan

A wear-resistant ceramic, non-stick pan technology, used in coatings, devices for coating liquids on surfaces, special materials for cooking utensils, etc., can solve problems such as easy cracking and poor wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] The preparation method of the wear-resistant ceramic coating non-stick pan of the present embodiment, it comprises the following steps:

[0029] Step S1: Put the metal pot body into the sand blasting machine, use silicon carbide ceramics as shot blasting, and perform sand blasting roughening treatment to form an uneven convex structure on the inner surface of the pot body, then degrease and clean it spare;

[0030] Step S2: In parts by weight, weigh 45 parts of boron-modified silica sol and 30 parts of silane-modified nano-titanium sol; Bentonite, stir and mix evenly to obtain a coating slurry; the boron-modified silica sol is boride-modified acidic silica sol, and its pH is 3.5; the silane-modified nano-titanium sol is nano-scale titanium oxide dispersed with oxalic acid The sol is used as a raw material, and then the vinyl chloride silane is hydrolyzed and co-condensed with the titanium oxide sol to obtain it; the pH of the silane-modified nano-titanium sol is 3.7, a...

Embodiment 2

[0039] The preparation method of the wear-resistant ceramic coating non-stick pan of the present embodiment, it comprises the following steps:

[0040] Step S1: Put the metal pot body into the sand blasting machine, use stainless steel beads as shot blasting, and perform sandblasting roughening treatment to form an uneven raised structure on the inner surface of the pot body, then perform degreasing treatment, and clean it for later use ;

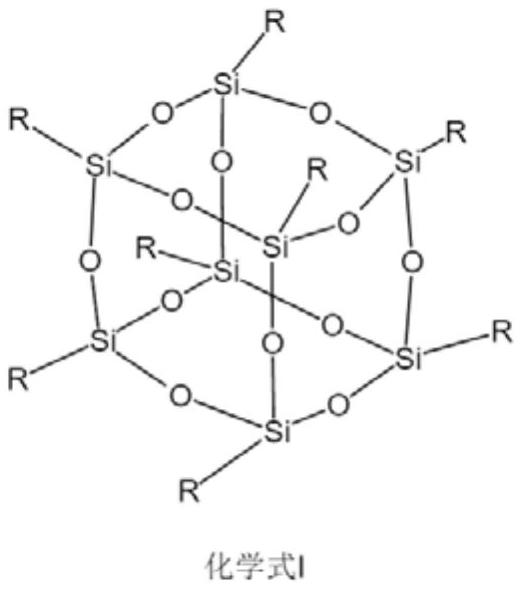

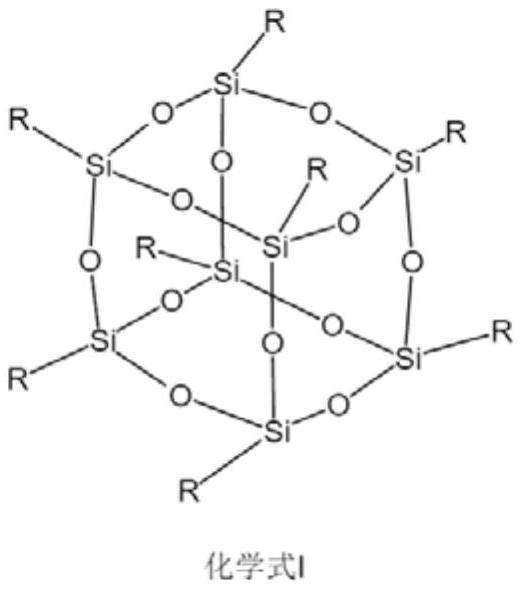

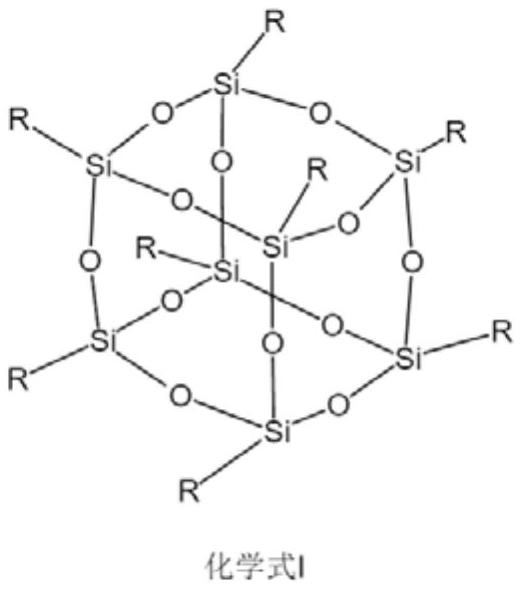

[0041] Step S2: In parts by weight, weigh 55 parts of boron-modified silica sol and 40 parts of silane-modified nano-titanium sol; and add 12 parts of long-chain olefin-substituted cage polysilsesquioxane and 3 parts of organobentonite , stir and mix evenly to obtain a coating slurry; the boron-modified silica sol is boride-modified acidic silica sol, and its pH is 4; the silane-modified nano-titanium sol is nano-scale oxidation Titanium sol is used as a raw material, and then obtained after co-condensation with the titanium oxide sol afte...

Embodiment 3

[0050] The preparation method of the wear-resistant ceramic coating non-stick pan of the present embodiment, it comprises the following steps:

[0051] Step S1: Put the metal pot body into the sand blasting machine, use silicon carbide ceramics as shot blasting, and perform sand blasting roughening treatment to form an uneven convex structure on the inner surface of the pot body, then degrease and clean it spare;

[0052] Step S2: In parts by weight, weigh 65 parts of boron-modified silica sol and 50 parts of silane-modified nano-titanium sol; Bentonite and 1.5 parts of organobentonite are stirred and mixed evenly to obtain a coating slurry; the boron-modified silica sol is boride-modified acidic silica sol, and its pH is 4.5; the silane-modified nano-titanium sol is prepared with formic acid The nano-scale titanium oxide sol dispersed with acetic acid is used as raw material, and then obtained after co-condensation with the titanium oxide sol after hydrolysis of vinyl chlori...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com