Automobile glass capable of preventing water stains from caking and preparation method thereof

An automotive glass and glass technology, applied in glass manufacturing equipment, glass molding, glass re-molding, etc., can solve the problems of high tempering strength, low tempering strength, large fragments, etc., achieve good lubricity and processability, prevent The effect of water congealing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

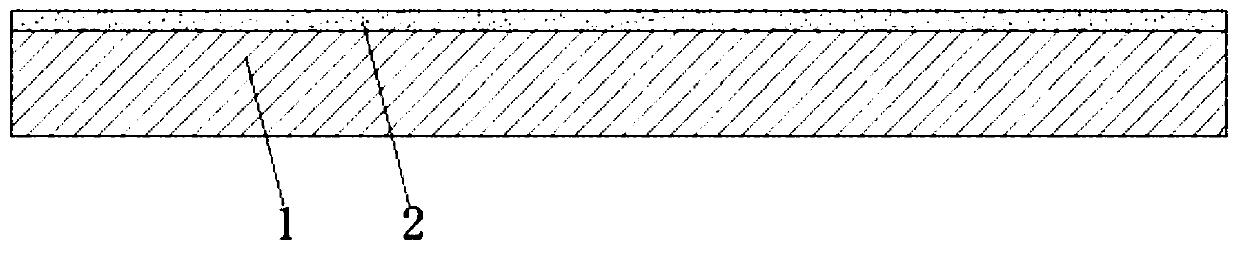

[0024] Embodiment one, with reference to Figure 1-3 , an automobile glass for preventing water stains and agglomeration, comprising a glass body 1, and a decontamination film 2 is arranged on one side of the outer wall of the glass body 1.

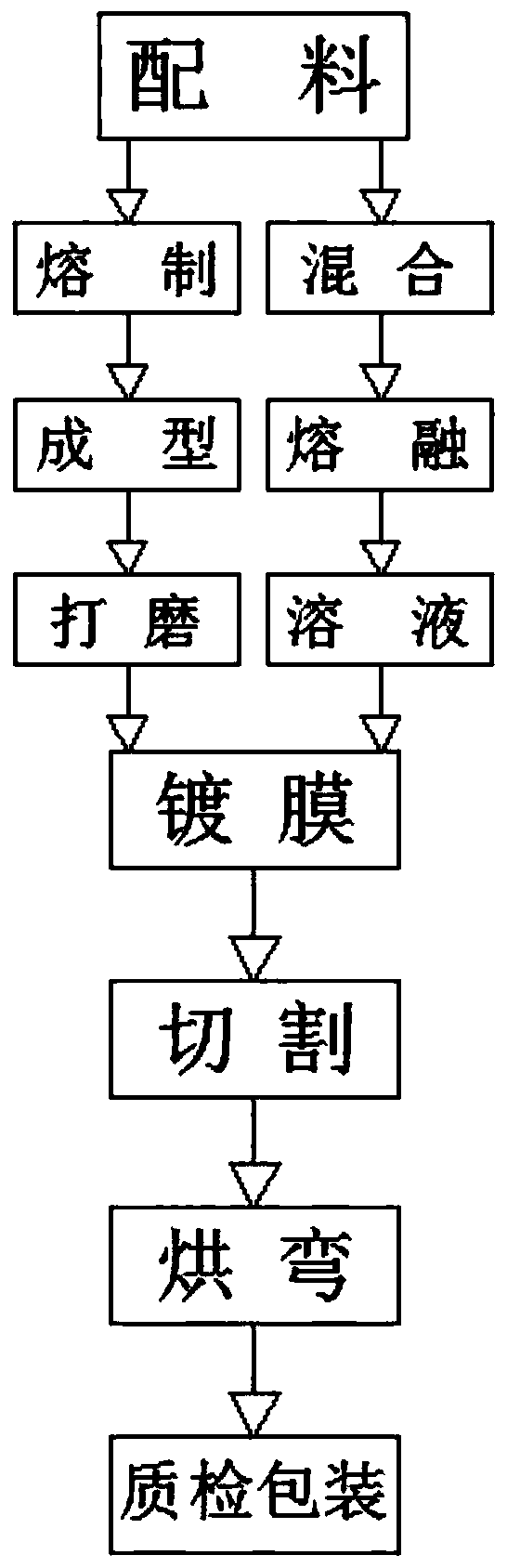

[0025] A kind of automobile glass preparation method that prevents water stain agglomeration, comprises the following steps:

[0026] S1: Ingredients, first prepare glass raw materials such as quartz sand, limestone, feldspar, soda ash, and boric acid, and then prepare raw materials for decontamination membranes such as nano-silica, nano-titanium dioxide, nano-zinc dioxide, and polyethylene wax;

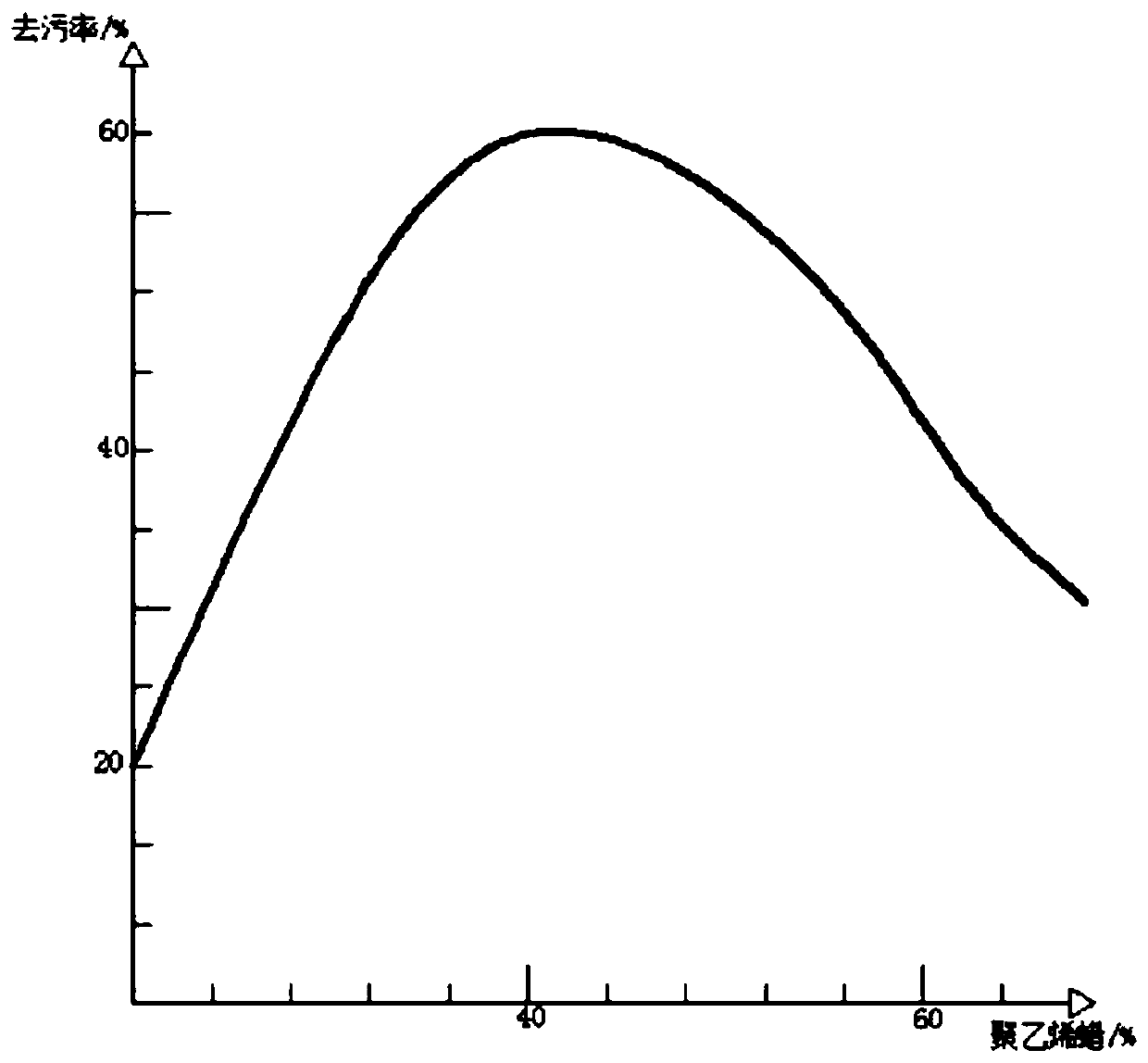

[0027] S2: Melting, the prepared raw materials are heated at high temperature to form a uniform glass liquid without bubbles; mixing, the prepared nano-silica, nano-titanium dioxide, nano-zinc dioxide and polyethylene wax are prepared according to the ratio of 2:3: The ratio of 3:2 is mixed to obtain a mixed solution,

[0028] S3: Forming, pou...

Embodiment 2

[0035] Embodiment two, refer to Figure 1-3 , an automobile glass for preventing water stains and agglomeration, comprising a glass body 1, and a decontamination film 2 is arranged on one side of the outer wall of the glass body 1.

[0036] A kind of automobile glass preparation method that prevents water stain agglomeration, comprises the following steps:

[0037] S1: Ingredients, first prepare glass raw materials such as quartz sand, limestone, feldspar, soda ash, and boric acid, and then prepare raw materials for decontamination membranes such as nano-silica, nano-titanium dioxide, nano-zinc dioxide, and polyethylene wax;

[0038] S2: Melting, the prepared raw materials are heated at high temperature to form a uniform glass liquid without bubbles; mixing, the prepared nano-silica, nano-titanium dioxide, nano-zinc dioxide and polyethylene wax are prepared according to the ratio of 2:2: The ratio of 2:4 is mixed to obtain a mixed solution,

[0039] S3: Forming, pouring the ...

Embodiment 3

[0046] Embodiment three, refer to Figure 1-3 , an automobile glass for preventing water stains and agglomeration, comprising a glass body 1, and a decontamination film 2 is arranged on one side of the outer wall of the glass body 1.

[0047] A kind of automobile glass preparation method that prevents water stain agglomeration, comprises the following steps:

[0048] S1: Ingredients, first prepare glass raw materials such as quartz sand, limestone, feldspar, soda ash, and boric acid, and then prepare raw materials for decontamination membranes such as nano-silica, nano-titanium dioxide, nano-zinc dioxide, and polyethylene wax;

[0049] S2: Melting, the prepared raw materials are heated at high temperature to form a uniform glass liquid without bubbles; mixing, the prepared nano-silica, nano-titanium dioxide, nano-zinc dioxide and polyethylene wax are prepared according to 2:1: The ratio of 1:6 is mixed to obtain a mixed solution,

[0050] S3: Forming, pouring the melted glass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com