Double-layer anti-adhesion polypropylene patch, and preparation method and application thereof

A polypropylene and anti-adhesion technology, which is applied in the field of medical materials, can solve the problems of small modification space, no anti-adhesion function, and poor anti-adhesion effect, and achieve stable properties, good hydrophilicity and biocompatibility Sexuality, texture smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

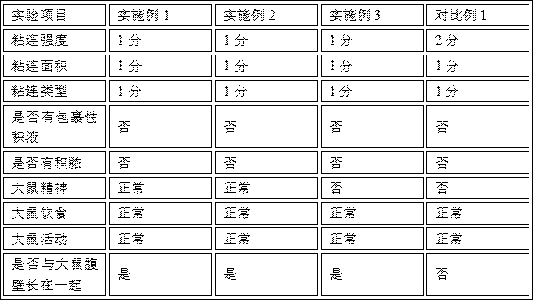

Examples

Embodiment 1

[0029] A double-layer anti-adhesion polypropylene patch, comprising a polypropylene monofilament layer and a polypropylene / polydopamine composite monofilament layer, the polypropylene monofilament layer is woven through a double-comb warp knitting process, and the polypropylene / poly The dopamine composite monofilament layer is woven through a three-comb warp knitting process, and the specific preparation process is as follows:

[0030] Step S1: Put polypropylene filaments with a diameter of 0.1-0.2mm into tris buffer solution with a concentration of 10mmol / L, add dopamine hydrochloride solution with a concentration of 2.4g / L, and adjust the pH of the solution to 8.0, Stir at a constant speed of 200 rpm / min at room temperature, take it out after 72 hours of reaction, rinse with deionized water and dry to obtain a polypropylene / polydopamine composite monofilament material;

[0031] Step S2: Knit the polypropylene filament with a diameter of 0.1-0.2mm and the polypropylene / polydo...

Embodiment 2

[0033] A double-layer anti-adhesion polypropylene patch, comprising a polypropylene monofilament layer and a polypropylene / polydopamine composite monofilament layer, the polypropylene monofilament layer is woven through a double-comb warp knitting process, and the polypropylene / poly The dopamine composite monofilament layer is woven through a three-comb warp knitting process, and the specific preparation process is as follows:

[0034] Step S1: put the polypropylene wire with a diameter of 0.1-0.2 mm into a tris buffer solution with a concentration of 20 mmol / L, add a dopamine hydrochloride solution with a concentration of 2.8 g / L, and adjust the pH of the solution to 8.0, Stir at a constant speed of 600 rpm / min at room temperature, take it out after 48 hours of reaction, rinse with deionized water and dry to obtain a polypropylene / polydopamine composite monofilament material;

[0035]Step S2: Knit the polypropylene filament with a diameter of 0.1-0.2mm and the polypropylene / p...

Embodiment 3

[0037] A double-layer anti-adhesion polypropylene patch, comprising a polypropylene monofilament layer and a polypropylene / polydopamine composite monofilament layer, the polypropylene monofilament layer is woven through a double-comb warp knitting process, and the polypropylene / poly The dopamine composite monofilament layer is woven through a three-comb warp knitting process, and the specific preparation process is as follows:

[0038] Step S1: Put the polypropylene wire with a diameter of 0.1-0.2 mm into a tris buffer solution with a concentration of 5 mmol / L, add a dopamine hydrochloride solution with a concentration of 1.2 g / L, and adjust the pH of the solution to 8.0, Stir at a constant speed of 300rpm / min at room temperature, take it out after 24 hours of reaction, rinse with deionized water and dry to obtain a polypropylene / polydopamine composite monofilament material; the polypropylene / polydopamine composite monofilament material is added to a deacetylation degree of 89%...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com