Method for solving problem of asphaltene coking in residual oil

A technology of asphaltene and coking, which is applied to the device for coating liquid on the surface, pretreatment of the surface, coating, etc., which can solve the problems of increasing investment cost, increasing safety risks, and affecting the long-term operation of the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

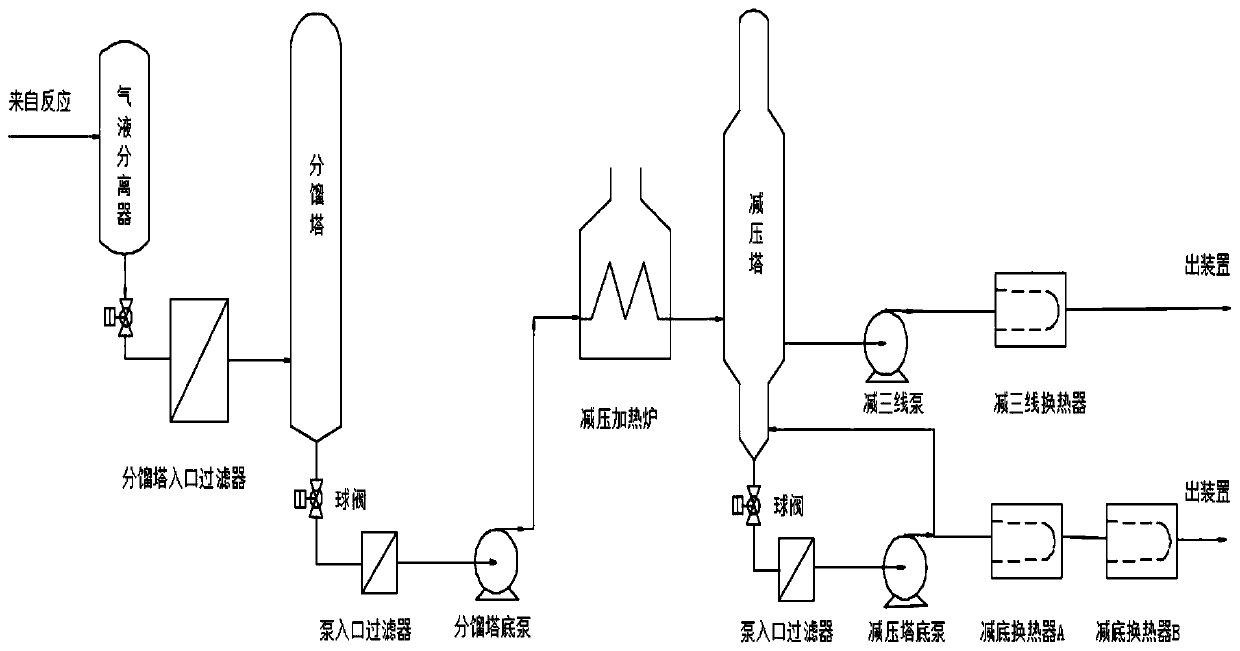

[0046] Such as figure 1 as shown,

[0047] For old equipment, check the fractionation column inlet filter, pump inlet filter, third-line heat exchanger, bottom-reduction heat exchanger A and bottom-reduction heat exchanger B, clean the inner surface, polish, and pre-treat. The cleaning here is mainly Including coke cleaning and high temperature steam purge cleaning.

[0048] Stir the high-temperature-resistant and anti-stick nano-composite ceramic coating on the curing machine evenly without precipitation; mix the cured high-temperature-resistant and anti-stick nano-composite ceramic coating with the curing agent of the aluminum silicate type in a mass ratio of 2:1, Roll and mature on the machine for about 5-7 days, and then filter the cured mixed paint through a 200-mesh filter. After filtering, the paint is the finished product and is ready for use.

[0049] The cleaning of the inner surface of fractionation column inlet filter, pump inlet filter, third-line heat exchanger...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com