Processing method of round chips and semiconductor wafer

A processing method and chip technology, which are applied in the process of producing decorative surface effects, metal material coating process, decorative arts, etc., can solve problems such as the difficulty of equipment research and development, achieve high dicing efficiency, improve cutting efficiency, The effect of reduced cutting stroke

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

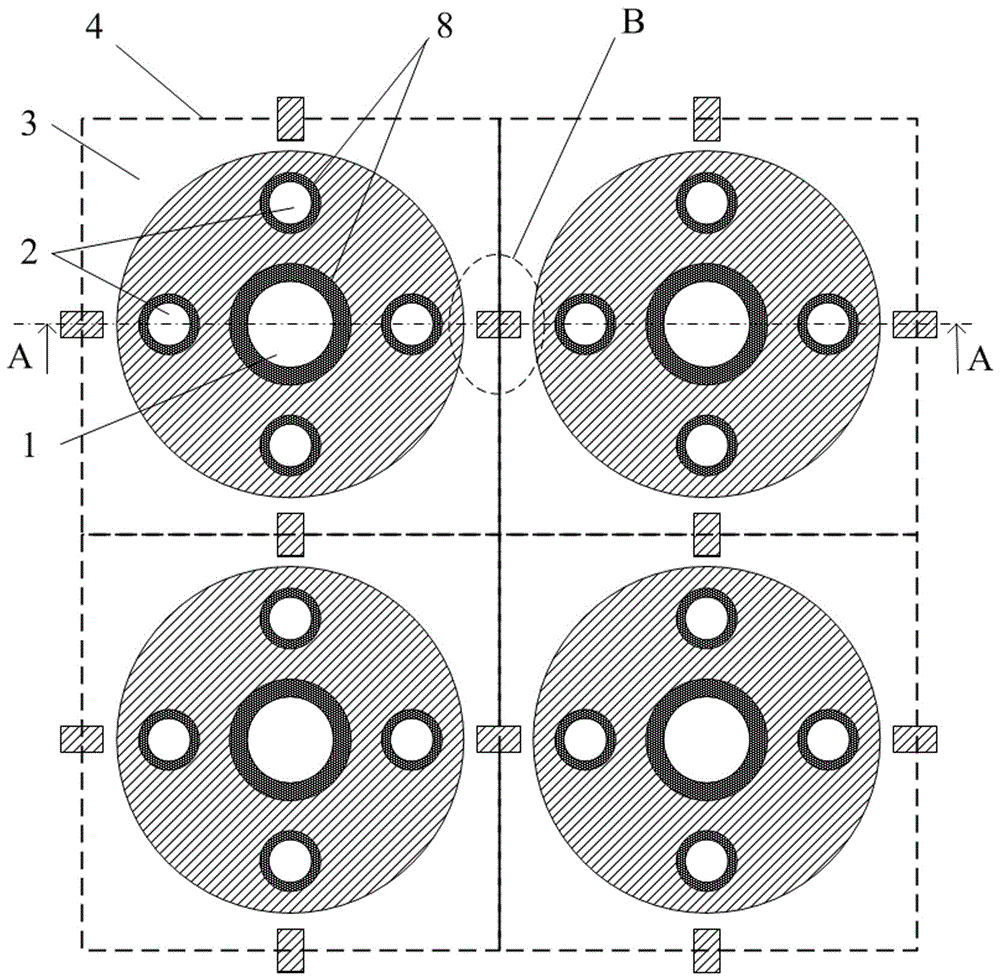

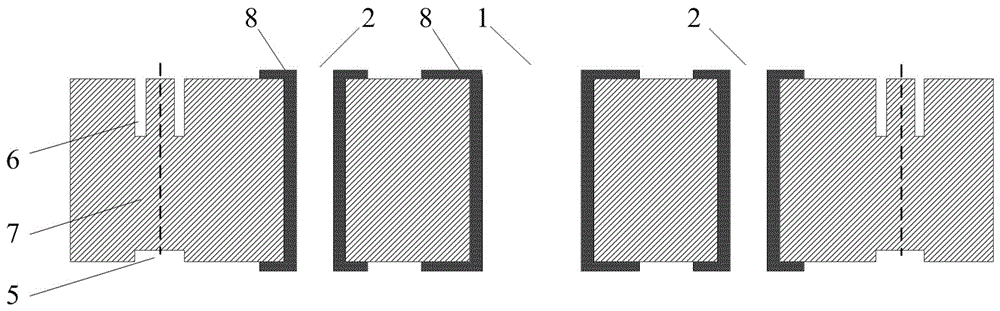

[0030] The invention provides a method for processing a circular chip and a wafer capable of cutting and separating the circular chip. The scribing process is simple and the difficulty is small. The grinding wheel dicing machine can be used to realize chip cutting and separation. At the same time, it has the advantages of small scribing stroke, high cutting efficiency, little damage to the appearance of the chip after dicing, and high mechanical strength.

[0031] Taking the preparation of a MEMS circulator chip as an example below, the processing method and wafer of the present invention will be further described in conjunction with the accompanying drawings.

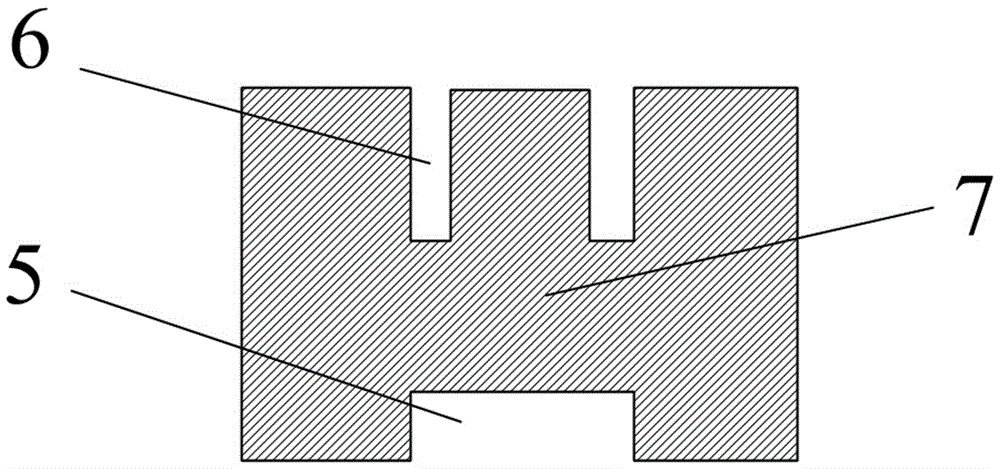

[0032] The MEMS circulator is a circular chip structure, and its processing method includes the following steps: the first step is to prepare the back cutting groove 5. The preparation of the back cutting groove 5 is formed by an RIE etching process, and a silicon wet etching process can also be used to cut the groove. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com