Water-soluble fertilizer with plant growth regulating function and production method thereof

A plant growth regulation and water-soluble fertilizer technology, applied in the direction of organic fertilizers, nitrogen fertilizers, phosphate fertilizers, etc., can solve the problems of high environmental impact on storage resistance, many product transportation constraints, and low nutrition in liquid fertilizers, so as to improve crop yields and quality, improve crop quality, and enhance the effect of crop stress resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

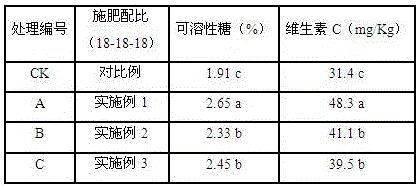

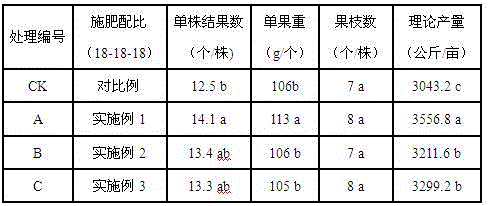

Examples

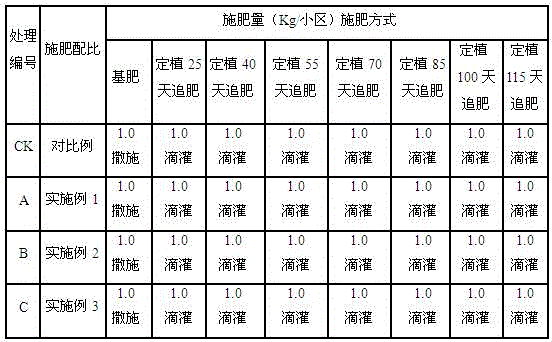

Embodiment 1

[0040] Components: 490 parts of ammonium nitrate phosphorus, 170 parts of potassium nitrate, 304 parts of potassium dihydrogen phosphate, 15 parts of fulvic acid, 8 parts of EDTA chelated trace elements, 8 parts of seaweed extract, 5 parts of potassium indole butyrate.

[0041] Preparation:

[0042] Step 1: Preparation of alginic acid extract

[0043] (1) Acid enzymatic hydrolysis: weigh 300g of dried kelp, add 10L of water, soak for 2h and wash twice; cut to size 1.5×1.5cm with a double shear 2 , Add water to 1800g (6 times the weight of dried kelp), add 500mL 0.2% dilute hydrochloric acid, add 34g cellulase dissolved in 400mL water, adjust the pH to 4.5-5.0 with 10% hydrochloric acid solution, and let stand for 12 -18h;

[0044] (2) Alkaline enzymatic hydrolysis: Pour the reaction solution after standing still into the reaction kettle, heat to 53°C and stir for 15 minutes. After adding 25g pectinase and 1700mL water to the reactor, adjust the pH to 7.5-8.0 with 10% soda ash solutio...

Embodiment 2

[0054] Components: 495 parts of ammonium nitrate phosphorus, 170 parts of potassium nitrate, 299 parts of potassium dihydrogen phosphate, 9 parts of fulvic acid, 12 parts of EDTA chelated trace elements, 15 parts of seaweed extract.

[0055] The preparation method is also in Example 1.

[0056] The obtained product has a specification of 18-18-18, contains fulvic acid, trace elements, seaweed extract, and does not contain plant regulators.

Embodiment 3

[0058] Components: 510 parts of ammonium nitrate phosphorus, 170 parts of potassium nitrate, 299 parts of potassium dihydrogen phosphate, 10 parts of fulvic acid, 11 parts of EDTA chelated trace elements.

[0059] The preparation method is the same as in Example 1.

[0060] The obtained product has a specification of 18-18-18, contains fulvic acid, trace elements, and does not contain seaweed extracts and plant regulators.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com