Method for preparing fluorescent carbon dots by pyrolyzing ammonium carboxylate

A technology of ammonium carboxylate salt and fluorescent carbon dots, which is applied in the direction of fluorescence/phosphorescence, chemical instruments and methods, luminescent materials, etc., can solve the problems of cumbersome process steps, low reaction yield, and difficulty in large-scale production and promotion, and achieve water-soluble Good performance, easy access to raw materials, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

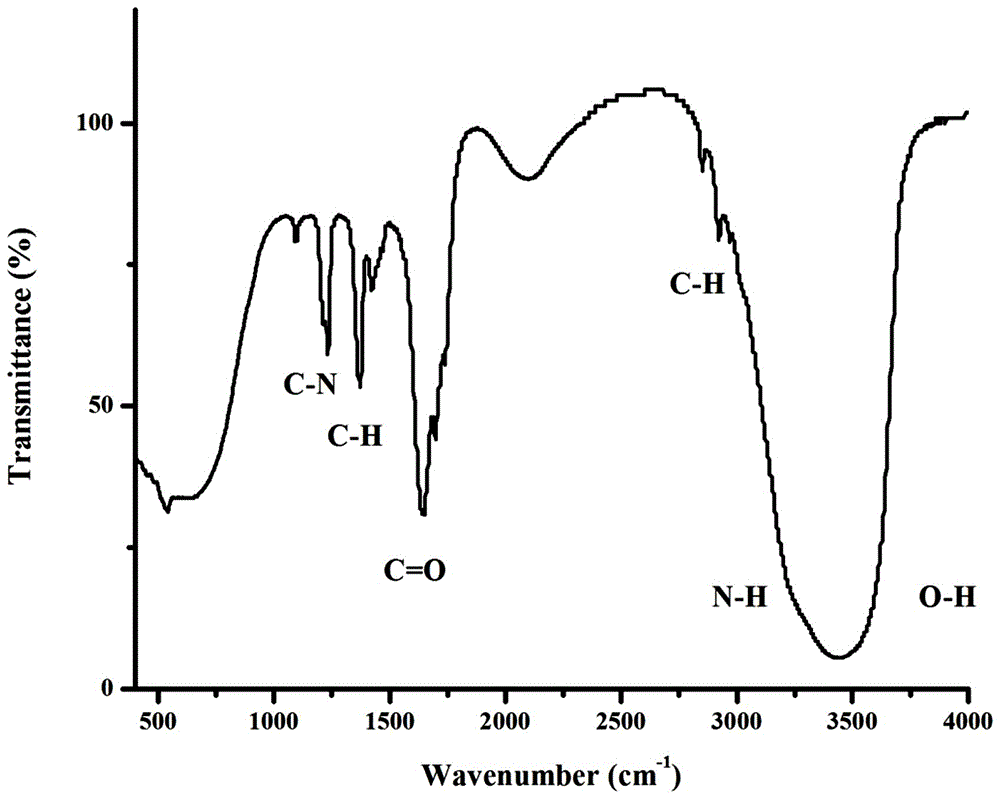

[0033] A method for preparing fluorescent carbon dots by pyrolyzing ammonium carboxylate salts is composed of the following steps:

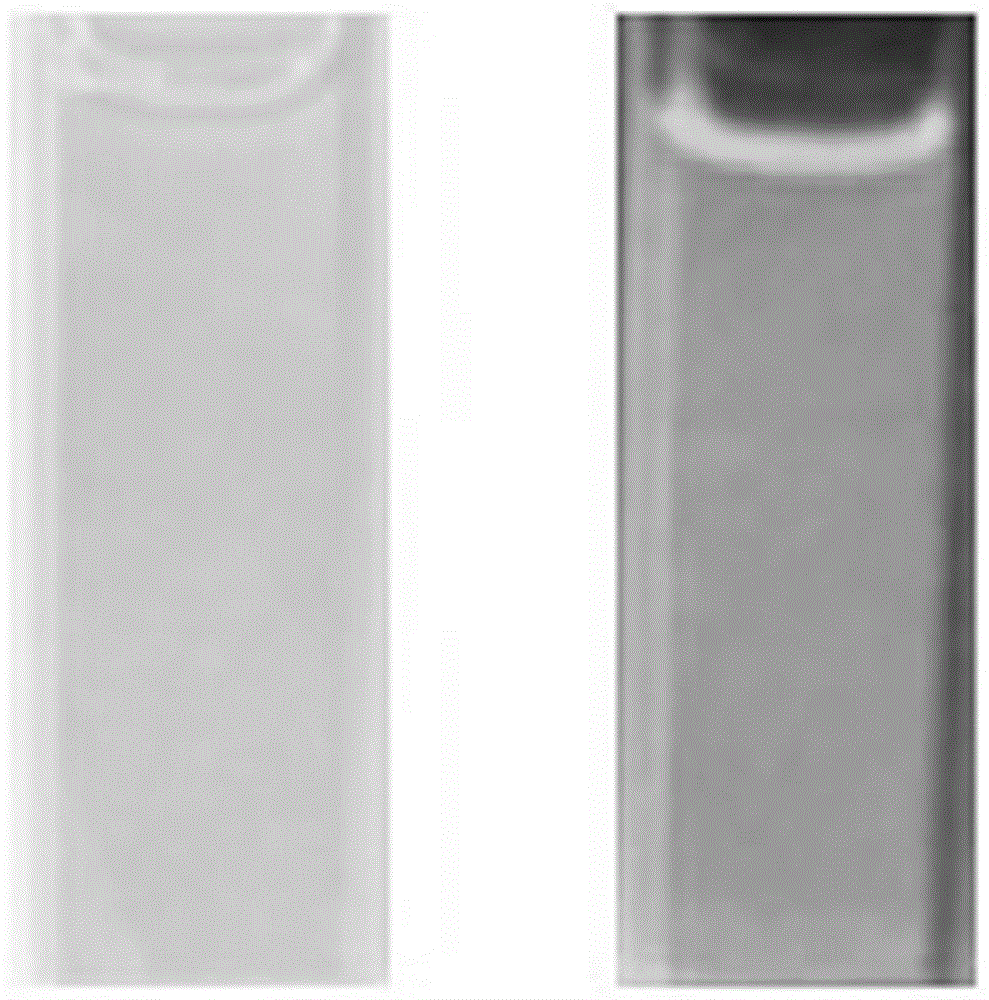

[0034] 1) Dissolve 1g of ethylenediaminetetraacetic acid in 10ml of deionized water (the mass ratio of ethylenediaminetetraacetic acid to deionized water is 1:10), ultrasonically oscillate for 5min, pour into a vacuum volumetric flask filled with nitrogen and stir, add 0.419g of ethylenediamine (the molar ratio of ethylenediaminetetraacetic acid to ethylenediamine is 1:2), reacted at 20°C for 8h, washed three times with petroleum ether after the reaction was complete, separated the water layer, and removed the unresolved residue by rotary evaporation under reduced pressure. The ethylenediamine of reaction, obtains yellow solid;

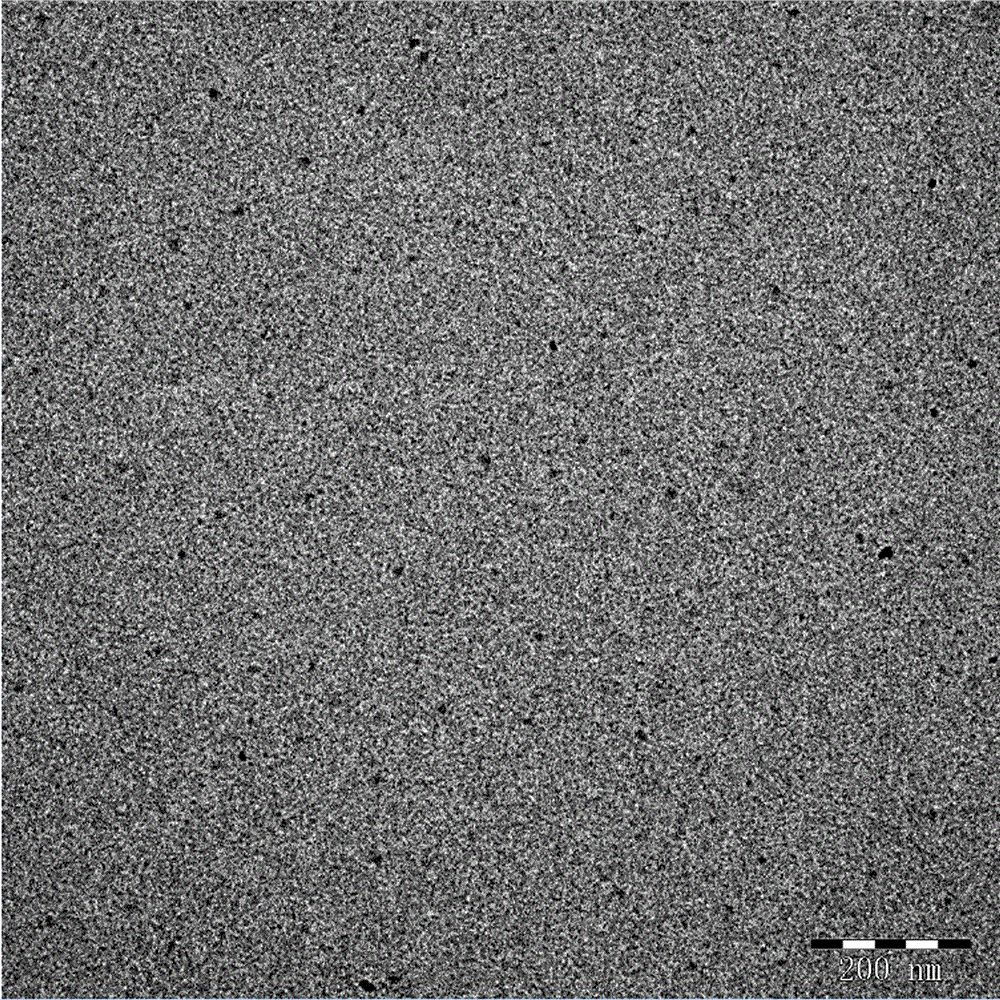

[0035] 2) Put the yellow solid in a tube furnace, heat it to 350°C under the protection of nitrogen, the heating rate is 5°C / min, keep it warm for 1.5h and grind it for 10min to get a black powder;

[0036] 3) Dissolve ...

Embodiment 2

[0039] A method for preparing fluorescent carbon dots by pyrolyzing ammonium carboxylate salts is composed of the following steps:

[0040] 1) Dissolve 1g of ethylenediaminetetraacetic acid in 10ml of deionized water (the mass ratio of ethylenediaminetetraacetic acid to deionized water is 1:10), ultrasonically oscillate for 5min, pour into a vacuum volumetric flask filled with nitrogen and stir, add 0.206g of ethylenediamine (the molar ratio of ethylenediaminetetraacetic acid to ethylenediamine is 1:1), react at 20°C for 8h, wash with petroleum ether three times after the reaction is complete, separate the water layer, and remove the unresolved residue by rotary evaporation under reduced pressure. The ethylenediamine of reaction, obtains yellow solid;

[0041] 2) Put the yellow solid in a tube furnace, heat it to 350°C under the protection of nitrogen, the heating rate is 5°C / min, keep it warm for 1.5h and grind it for 10min to get a black powder;

[0042] 3) Dissolve the bla...

Embodiment 3

[0045] A method for preparing fluorescent carbon dots by pyrolyzing ammonium carboxylate salts is composed of the following steps:

[0046] 1) Dissolve 1g of ethylenediaminetetraacetic acid in 10ml of deionized water (the mass ratio of ethylenediaminetetraacetic acid to deionized water is 1:10), ultrasonically oscillate for 5min, pour into a vacuum volumetric flask filled with nitrogen and stir, add 0.617g of ethylenediamine (the molar ratio of ethylenediaminetetraacetic acid to ethylenediamine is 1:3), reacted at 20°C for 8h, washed three times with petroleum ether after the reaction was complete, separated the water layer, and removed the unresolved residue by rotary evaporation under reduced pressure. The ethylenediamine of reaction, obtains yellow solid;

[0047] 2) Put the yellow solid in a tube furnace, heat it to 350°C under the protection of nitrogen, the heating rate is 5°C / min, keep it warm for 1.5h and grind it for 10min to get a black powder;

[0048] 3) Dissolve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com