Rice-flavored highland barley wine and preparation method thereof

A production method and technology of highland barley wine, applied in the field of wine making, can solve the problems of low wine yield, slow fermentation, low utilization rate of raw materials, etc., and achieve the effects of improving wine yield, obvious flavor and reducing production cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

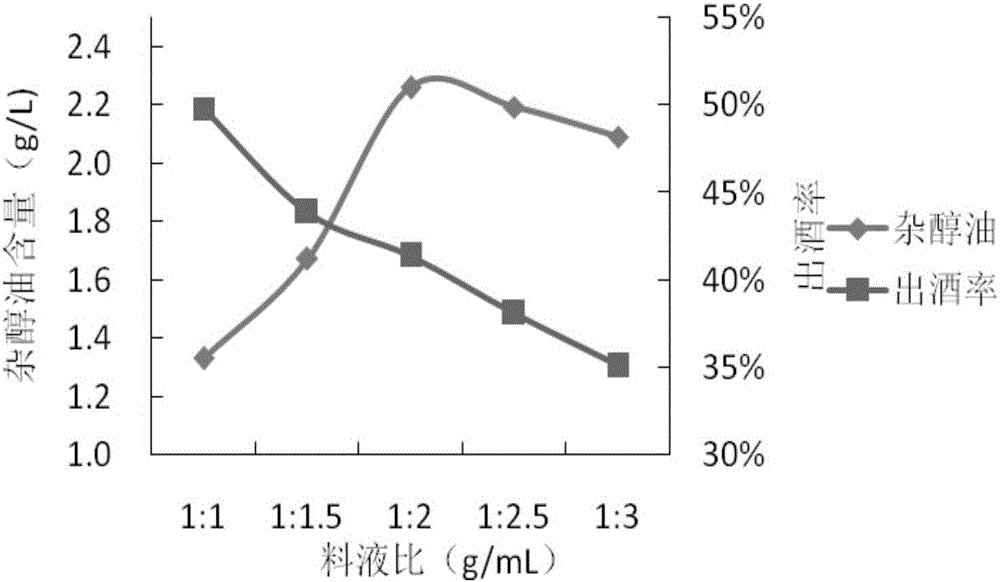

[0058] a. According to the weight ratio of highland barley: rice = 1: 2, weigh two kinds of raw materials. After washing the highland barley, boil it in boiling water to break the skin until it blooms, so that the highland barley can be cooked; after washing the rice, use water with a material-to-liquid ratio of 1: 3g / mL Soaking for 1 hour, steaming the soaked rice to obtain cooked rice; then uniformly mixing the cooked highland barley and cooked rice and cooling down to room temperature for later use;

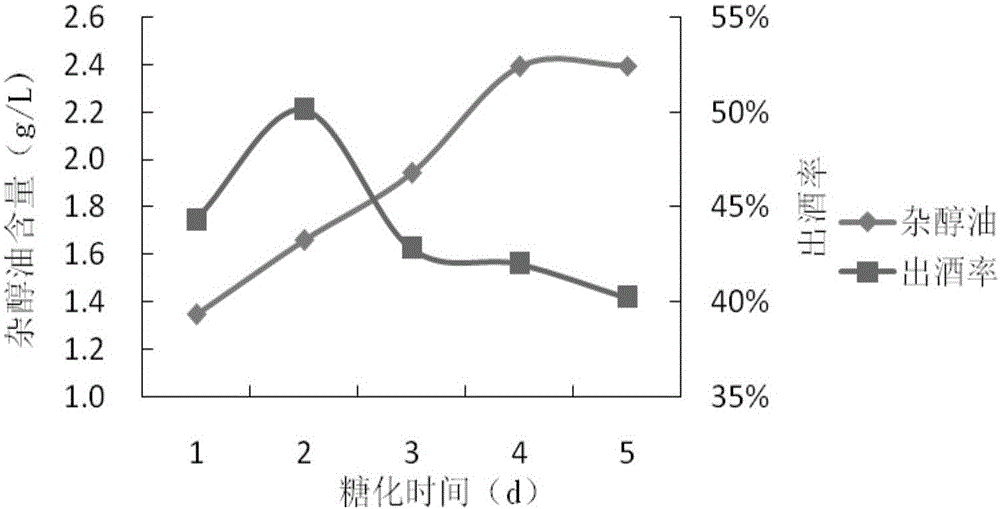

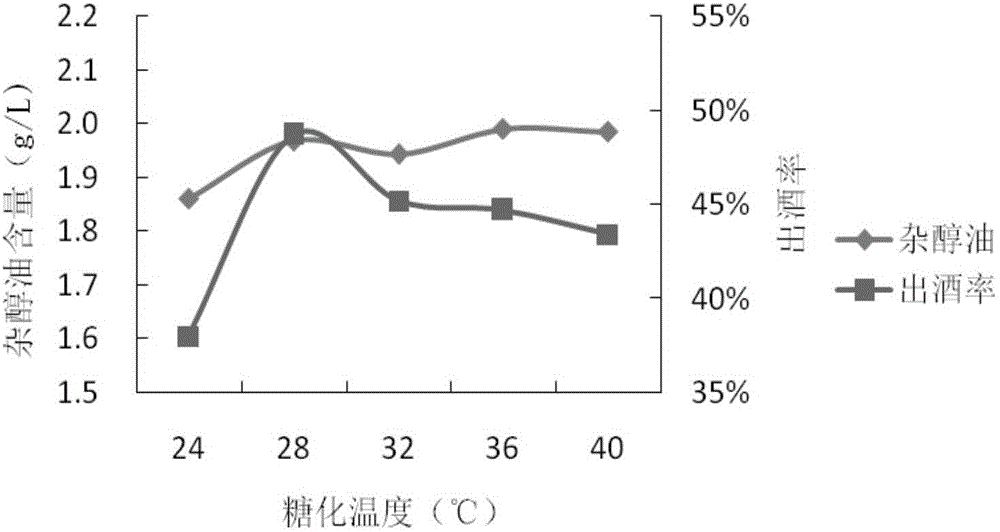

[0059] b. According to the total weight percentage of raw materials, add 0.4% Yinli distiller's koji by the total weight of untreated highland barley and rice to the uniformly mixed cooked highland barley and cooked rice, build a nest, and saccharify at 28°C for 2 days to obtain saccharified Rice fermented grains;

[0060] c. Add the saccharified rice unstrained spirits into boiling water cooled to room temperature according to the material-to-liquid ratio of 1:1g / mL, and then...

Embodiment 2

[0063] a. According to the weight ratio of highland barley: rice = 1: 3, weigh two kinds of raw materials. After washing the highland barley, boil it in boiling water to break the skin until it blooms, so that the highland barley can be cooked; after washing the rice, use water with a material-to-liquid ratio of 1: 3g / mL Soaking for 1 hour, steaming the soaked rice to obtain cooked rice; then uniformly mixing the cooked highland barley and cooked rice and cooling down to room temperature for later use;

[0064] b. According to the total weight percentage of raw materials, add 0.45% Yinli distiller's koji of untreated highland barley and rice into the uniformly mixed cooked highland barley and cooked rice, build a nest, and saccharify at 28°C for 1d to obtain saccharified Rice fermented grains;

[0065] c. Add the saccharified rice unstrained spirits into boiling water cooled to room temperature according to the material-to-liquid ratio of 1:1g / mL, and then ferment at 24°C for ...

Embodiment 3

[0068] a. According to the weight ratio of highland barley: rice = 1: 4, weigh the two raw materials. After washing the highland barley, boil it in boiling water to break the skin until it blooms, so that the highland barley can be cooked; after washing the rice, use water with a material-to-liquid ratio of 1: 4g / mL Soaking for 3 hours, steaming the soaked rice to obtain cooked rice; then uniformly mixing the cooked highland barley and cooked rice and cooling down to room temperature for later use;

[0069] b. According to the total weight percentage of raw materials, add 0.4% Yinli distiller's koji of untreated highland barley and rice into the uniformly mixed cooked highland barley and cooked rice, build a nest, and saccharify at 32°C for 1 day to obtain saccharified Rice fermented grains;

[0070] c. Add the saccharified rice unstrained spirits into boiling water cooled to room temperature according to the ratio of material to liquid: 1:1.5g / mL, and then ferment at 20°C for...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com