Heat strong titanium alloy ingot for aviation and manufacturing method for heat strong titanium alloy

A titanium alloy and aviation technology, applied in the field of titanium alloy materials, can solve the problems of large melting point temperature gradient of main elements, refractory blocks, etc., and achieve the effect of solving composition segregation, homogenizing composition, and improving composition uniformity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0035] A kind of preparation method of the heat-strength titanium alloy casting ingot for aviation of the present invention, specifically comprises the following steps:

[0036] Step 1, according to the weight percentage of elements: 6.2% to 7.3% Al, 0.4% to 1.0% Mo, 3.5% to 4.5% Zr, 0.5% to 1.5% Nb, 2.0% to 3.0% Sn, 0.1% to 0.25% Si, 0.04% to 0.15% O, 0.05% to 0.14% C, the balance is Ti, the sum of the weight percentages of the above components is 100%, weigh 40Al55Mo5Ti alloy, Ti80Sn alloy, Ti50Si alloy, Nb47Ti alloy and 5-9mm particle size Small particles of zirconium sponge, aluminum beans, TiO 2 Powder, C powder and first-class small particle sponge titanium with a particle size of 5-10 mm are mixed with the above raw materials for a single electrode, and then pressed into an electrode block;

[0037] Step 2, the electrode block obtained in step 1 is welded into an electrode by using a non-tungsten argon shielded plasma box;

[0038] Step 3, put the electrode prepared i...

Embodiment 1

[0045] Step 1, according to the weight percentage of elements: 6.2% Al, 0.4% ~ 1.0% Mo, 4.5% Zr, 1.0% Nb, 2.0% Sn, 0.2% Si, 0.1% O, 0.08% C, the balance is Ti, the above group The sum of the percentages by weight is 100%, weigh 40Al55Mo5Ti alloy, Ti80Sn alloy, Ti50Si alloy, Nb47Ti alloy and small particles of zirconium sponge, aluminum beans, TiO 2 Powder, C powder and first-class small particle sponge titanium with a particle size of 5-10 mm are mixed with the above raw materials for a single electrode, and then pressed into an electrode block;

[0046] Step 2, the electrode block obtained in step 1 is welded into an electrode by using a non-tungsten argon shielded plasma box;

[0047] Step 3, put the electrode prepared in step 2 into a vacuum consumable electric arc furnace for two vacuum smelting. During the smelting process, the smelting speed is controlled by controlling the current. The parameters are as follows:

[0048]

[0049]

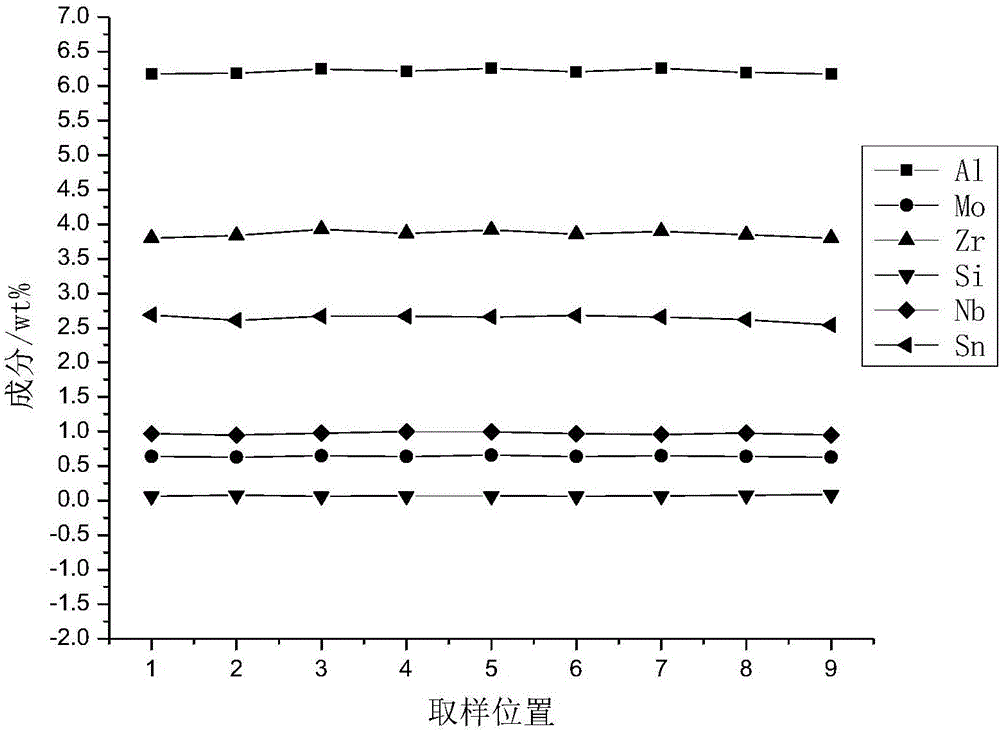

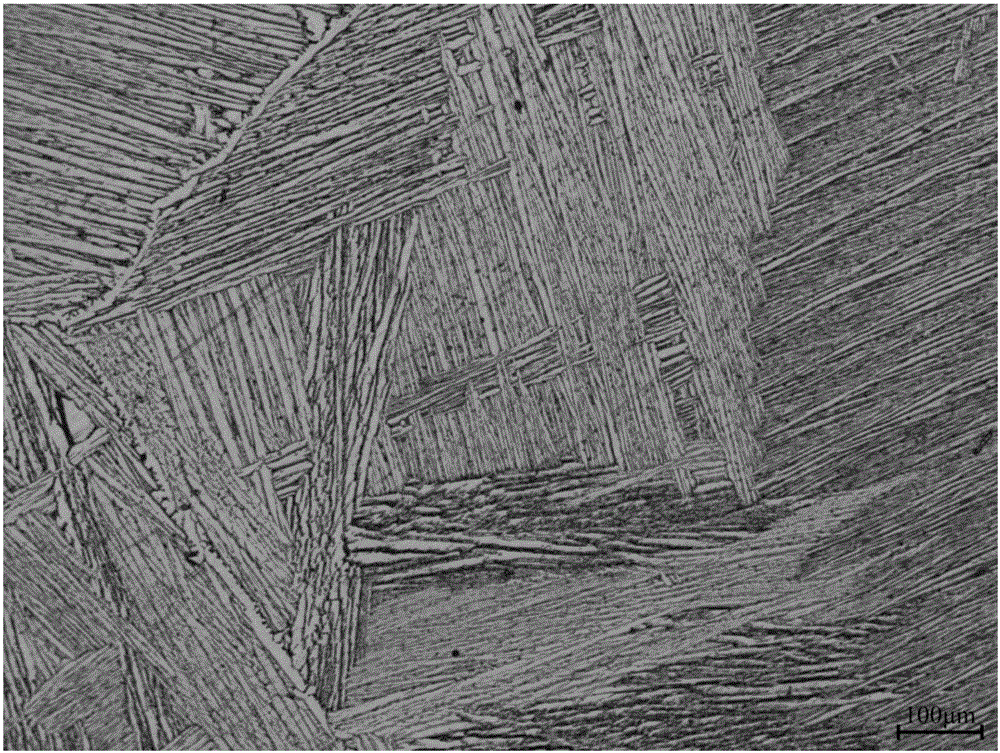

[0050] A heat-strength titanium...

Embodiment 2

[0052] Step 1, according to the weight percentage of elements: 7.3% Al, 0.8% Mo, 4.0% Zr, 0.5% Nb, 2.5% Sn, 0.25% Si, 0.04% O, 0.14% C, the balance is Ti, the weight percentage of the above components The sum is 100%, weigh 40Al55Mo5Ti alloy, Ti80Sn alloy, Ti50Si alloy, Nb47Ti alloy and small particles of zirconium sponge, aluminum beans, TiO 2 The powder and the first-class small particle sponge titanium with a particle size of 5-10 mm are mixed with the above raw materials for a single electrode, and then pressed into an electrode block;

[0053] Step 2, the electrode block obtained in step 1 is welded into an electrode by using a non-tungsten argon shielded plasma box;

[0054] Step 3, put the electrode prepared in step 2 into a vacuum consumable electric arc furnace for three times of vacuum smelting. During the smelting process, the smelting speed is controlled by controlling the current. The parameters are as follows:

[0055]

[0056]

[0057] A heat-strength tit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com