Preparation equipment for high-throughput experiment samples

A high-throughput, sample-based technology, applied in the preparation of test samples, etc., can solve problems such as low efficiency, stretching, and long basic data cycle, and achieve the effect of simple structure and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

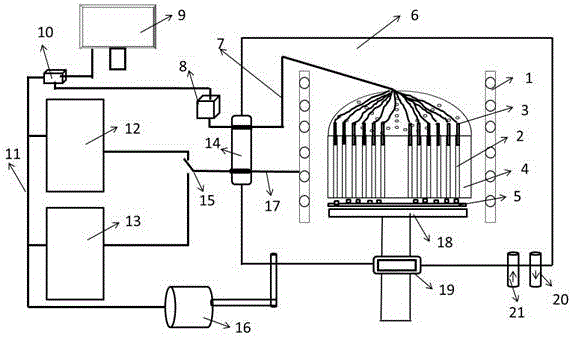

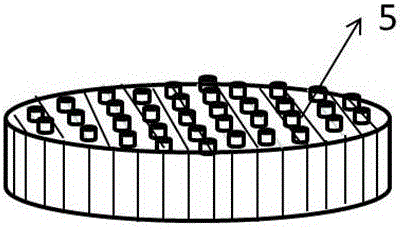

[0023] In this embodiment, austenitic stainless steel is used as the experimental material to calculate the relationship between composition, solidification structure and magnetic field strength. 5 concentric circles, 12 crucibles are pre-embedded at the same angle on each circle, and the material of the crucibles is alumina, such as figure 1shown. Divide the designed 12 kinds of austenitic stainless steel raw materials into 5 parts, put 12 kinds of austenitic stainless steel raw materials into 12 crucibles on each concentric circle, and put the crucibles on the same angle of the 5 concentric circles on the central axis as Same raw material. The temperature of each crucible is measured separately, and the austenitic stainless steel raw material is put into the crucible at a pre-designed position. Start the mechanical pump to evacuate (vacuum degree is 10-1Pa), open the intake valve to feed high-purity argon or nitrogen, repeat twice, start the intermediate frequency inductio...

Embodiment 2

[0025] In this embodiment, aluminum-copper alloy materials are used to count the relationship between composition-solidification structure-cooling intensity. The specific process is as follows: the casting mold for the experiment is cylindrical and made of magnesia bricks. circle, 12 crucibles are pre-embedded at the same angle on each circle, and the material of the crucible is quartz, such as figure 1 shown. Divide the designed 12 kinds of aluminum-copper alloy raw materials into 5 parts, and put 12 kinds of aluminum-copper alloy raw materials into 12 crucibles on each concentric circle. The crucibles on the same angle of the 5 concentric circles on the central axis are of the same type raw material. The temperature of each crucible is measured separately, and the aluminum-copper alloy raw material is put into the crucible at a pre-designed position. Start the mechanical pump to evacuate (vacuum degree is 10-1Pa), open the inlet valve to feed high-purity argon or nitrogen,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com