Integrated testing device and method for compression rigidity and bending rigidity of metal bipolar plate

A metal bipolar plate, bending stiffness technology, applied in the direction of measuring device, using stable bending force to test material strength, using stable tension/pressure to test material strength, etc., can solve the problem of inability to test the stiffness of metal bipolar plate , the compressive stiffness and bending stiffness were not retrieved, and the maximum pressure value of the component could not be recorded, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The specific implementation process of the present invention will be further described in conjunction with the accompanying drawings.

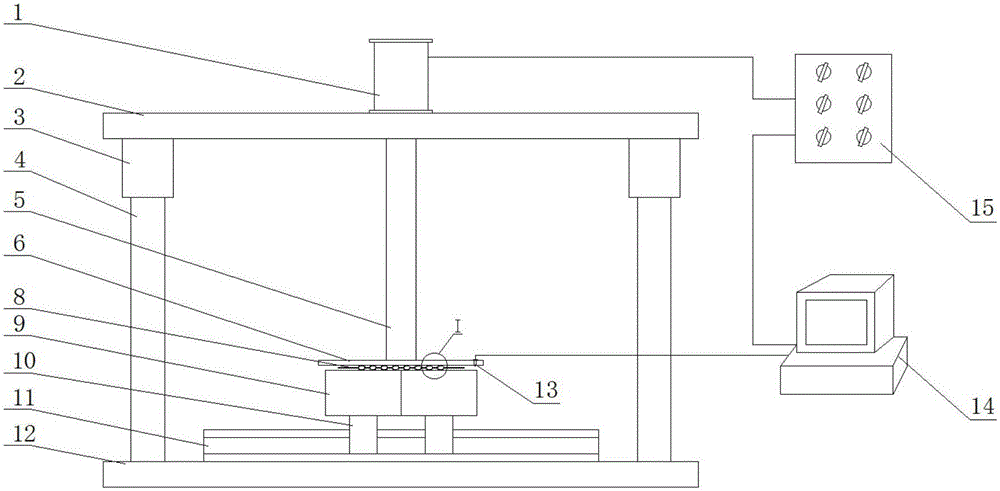

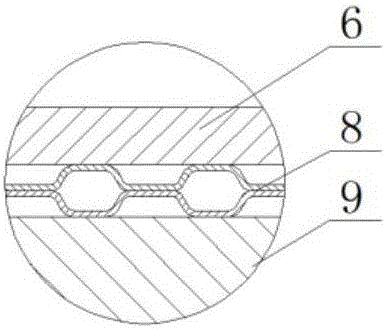

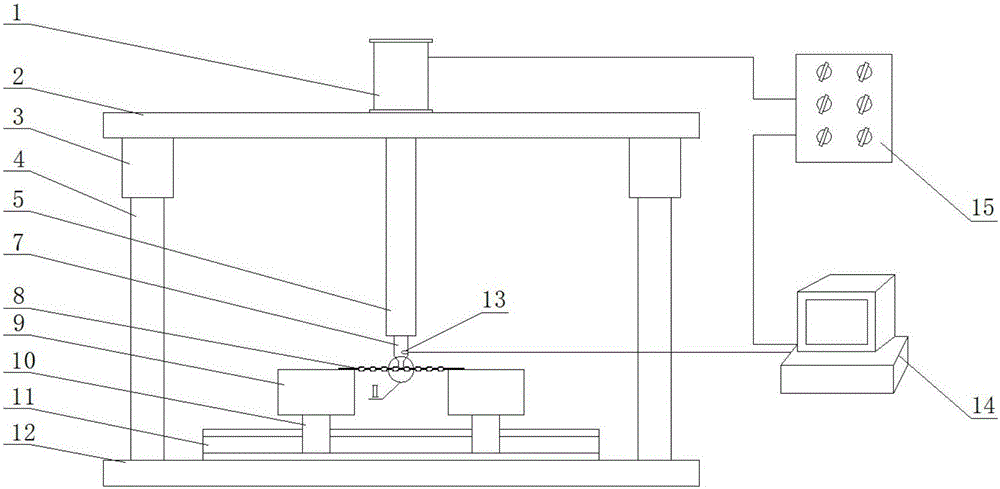

[0037] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 As shown, a metal bipolar plate compression and bending rigidity integrated test device consists of a hydraulic system 1, a support plate 2, a guide sleeve 3, a guide post 4, a dowel bar 5, a pressure plate 6, a pressure head 7, a metal Bipolar plate 8, support platform 9, slide block 10, slide rail 11, workbench 12, displacement sensor 13, data processing system 14 and hydraulic control system 15 constitute.

[0038] The workbench 12 and the support plate 2 are rectangular rigid bodies correspondingly matched, and a guide column 4 is respectively fixed on the left and right sides of the workbench 12, and the guide sleeve 3 is fixed at the position corresponding to the guide column 4 fixed on the support plate 2 and the workbench 12; The sleeve 3 is equipped wit...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com