Silicon-based SERS chip for quantitatively detecting lead ion concentration in actual water sample and preparation method thereof

A quantitative detection, lead ion technology, applied in measurement devices, instruments, material analysis by optical means, etc., can solve the problems of unsatisfactory sensitivity and reproducibility, limited application, etc., to achieve good selectivity and reliability. cyclic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

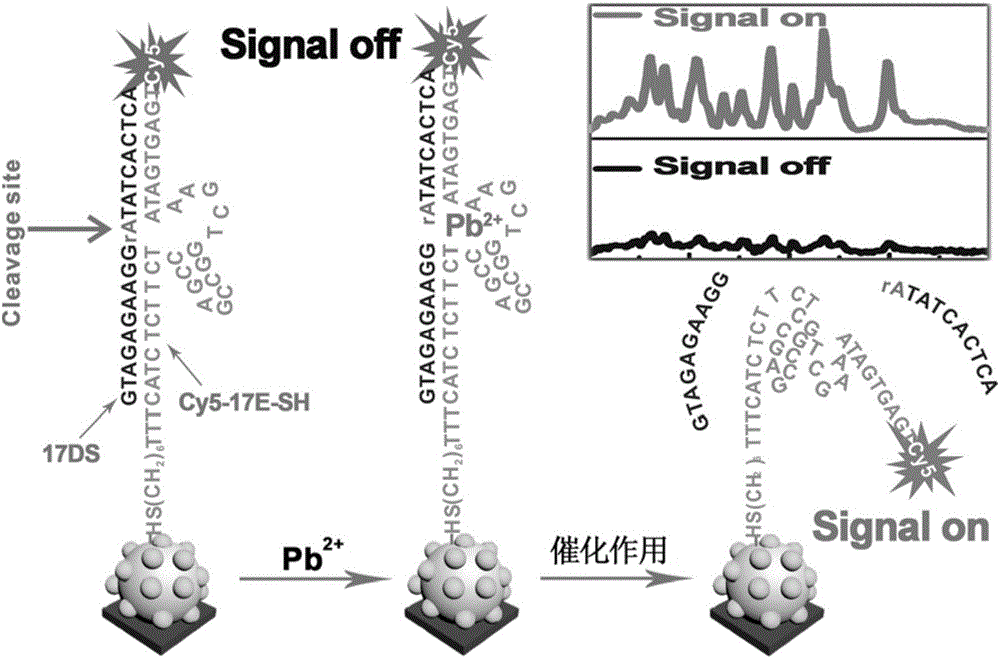

AI Technical Summary

Problems solved by technology

Method used

Image

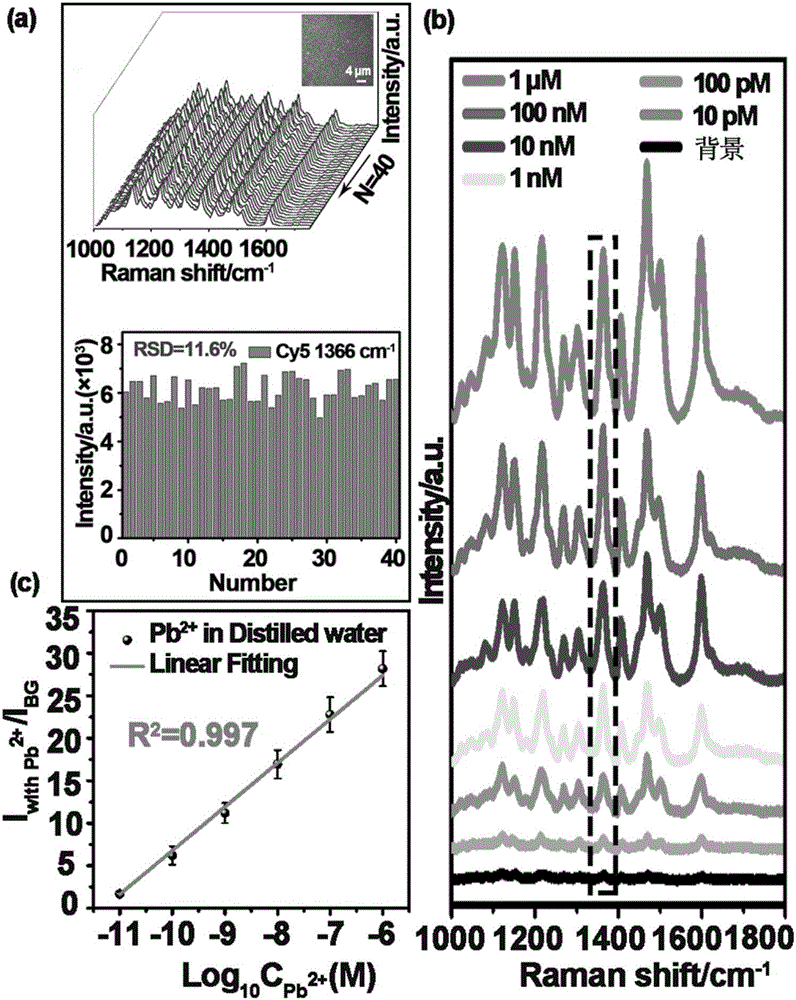

Examples

Embodiment 1

[0044] Embodiment 1: Preparation of the silicon-based SERS chip of the present invention

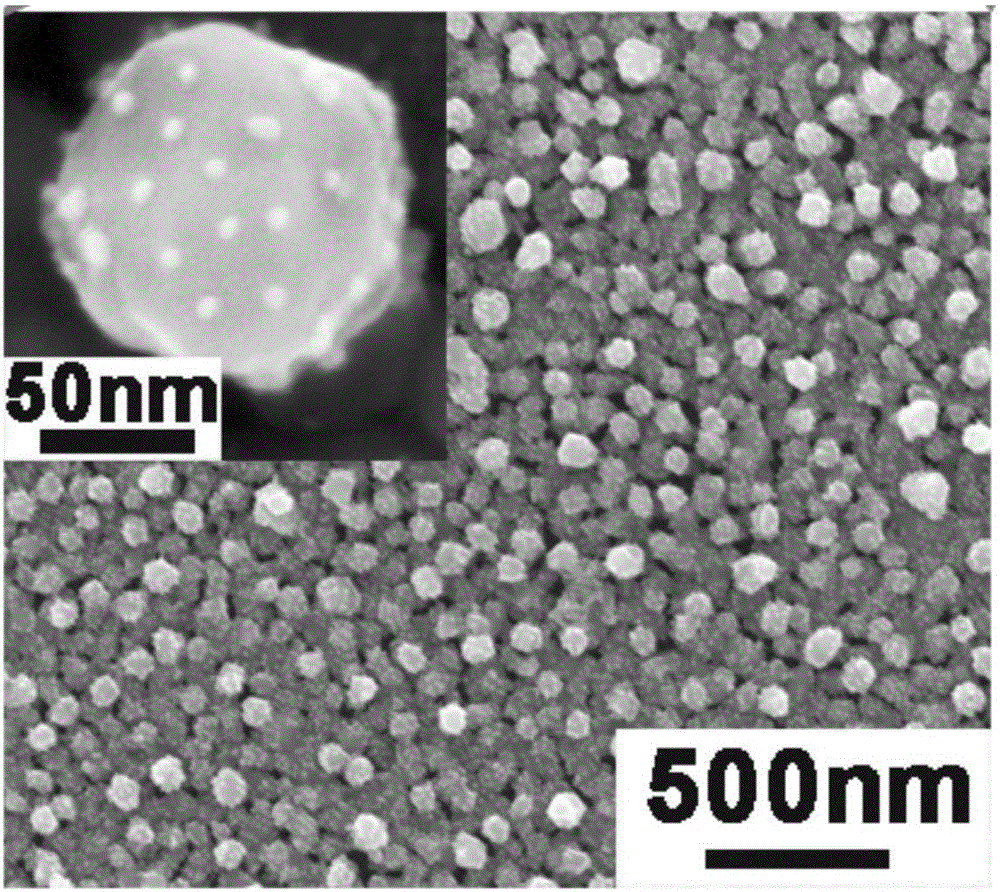

[0045] (1) Preparation of silver nanoparticles modified silicon wafers by hydrofluoric acid assisted etching method

[0046] Take 0.5cm 2 3-6 single crystal silicon wafers of large and small sizes were placed in a clean beaker and ultrasonically cleaned with deionized water, acetone, and deionized water for 15 minutes in an ultrasonic instrument, and then 40 mL of concentrated sulfuric acid and hydrogen peroxide (mass concentration: 40 %) mixed solution (volume ratio=3:1) for further cleaning, and then cleaning with deionized water to obtain a clean silicon wafer. Put the cleaned silicon wafer into a hydrofluoric acid solution (mass concentration: 5%) for silicon-hydrogenation reaction, shake slowly for 30 minutes, and obtain a silicon wafer covered with a large number of Si-H bonds on the surface. Put the silicon wafer obtained after the above treatment with the shiny side up, into 20...

Embodiment 2

[0051] Embodiment 2: Preparation of the silicon-based SERS chip of the present invention

[0052] (1) Preparation of silver nanoparticles modified silicon wafers by hydrofluoric acid assisted etching method

[0053] Take 0.5cm 2 3-6 single crystal silicon wafers of large and small sizes were placed in a clean beaker and ultrasonically cleaned with deionized water, acetone, and deionized water for 15 minutes in an ultrasonic instrument, and then 40 mL of concentrated sulfuric acid and hydrogen peroxide (mass concentration: 40 %) mixed solution (volume ratio=3:1) for further cleaning, and then cleaning with deionized water to obtain a clean silicon wafer. Put the cleaned silicon wafer into a hydrofluoric acid solution (mass concentration: 5%) for silicon-hydrogenation reaction, shake slowly for 30 minutes, and obtain a silicon wafer covered with a large number of Si-H bonds on the surface. Put the silicon wafer obtained after the above treatment with the shiny side up, into 20...

Embodiment 3

[0058] Embodiment 3: Preparation of the silicon-based SERS chip of the present invention

[0059] (1) Preparation of silver nanoparticles modified silicon wafers by hydrofluoric acid assisted etching method

[0060] Take 0.5cm 2 3-6 single crystal silicon wafers of large and small sizes were placed in a clean beaker and ultrasonically cleaned with deionized water, acetone, and deionized water for 15 minutes in an ultrasonic instrument, and then 40 mL of concentrated sulfuric acid and hydrogen peroxide (mass concentration: 40 %) mixed solution (volume ratio=3:1) for further cleaning, and then cleaning with deionized water to obtain a clean silicon wafer. Put the cleaned silicon wafer into a hydrofluoric acid solution (mass concentration: 5%) for silicon-hydrogenation reaction, shake slowly for 30 minutes, and obtain a silicon wafer covered with a large number of Si-H bonds on the surface. Put the silicon wafer obtained after the above treatment with the shiny side up, into 20...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com