Photoetching and etching method for preventing shaped wafer surface from etching damage

A surface etching and wafer technology, applied in electrical components, semiconductor/solid-state device manufacturing, circuits, etc., can solve the problems of etching damage, insufficient barrier of advanced patterned film in gate polysilicon area, etc., saving time and cost. cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to make the content of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with specific embodiments and accompanying drawings.

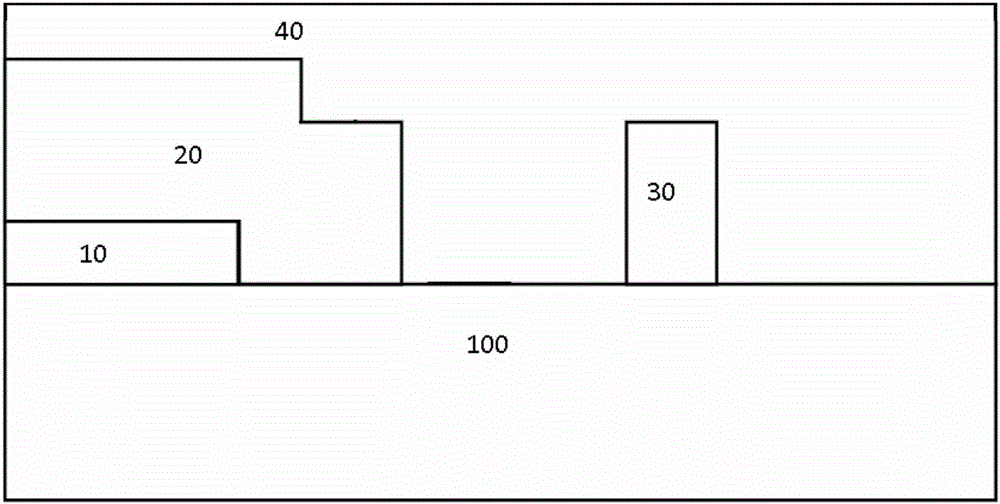

[0034] The invention adopts an innovative high-level patterned thin film planarization process to solve the problem of etching damage that often occurs on the surface of a shaped wafer. In the present invention, the surface topography of the wafer is filled and leveled by the gap filling material, and then the planarization process is carried out to realize the surface planarization of the advanced patterned film, and then the photolithography and etching process are carried out to solve the problem of the surface pattern of the wafer. Etching damage due to height difference.

[0035] Specific preferred embodiments of the present invention will be described below in conjunction with the accompanying drawings.

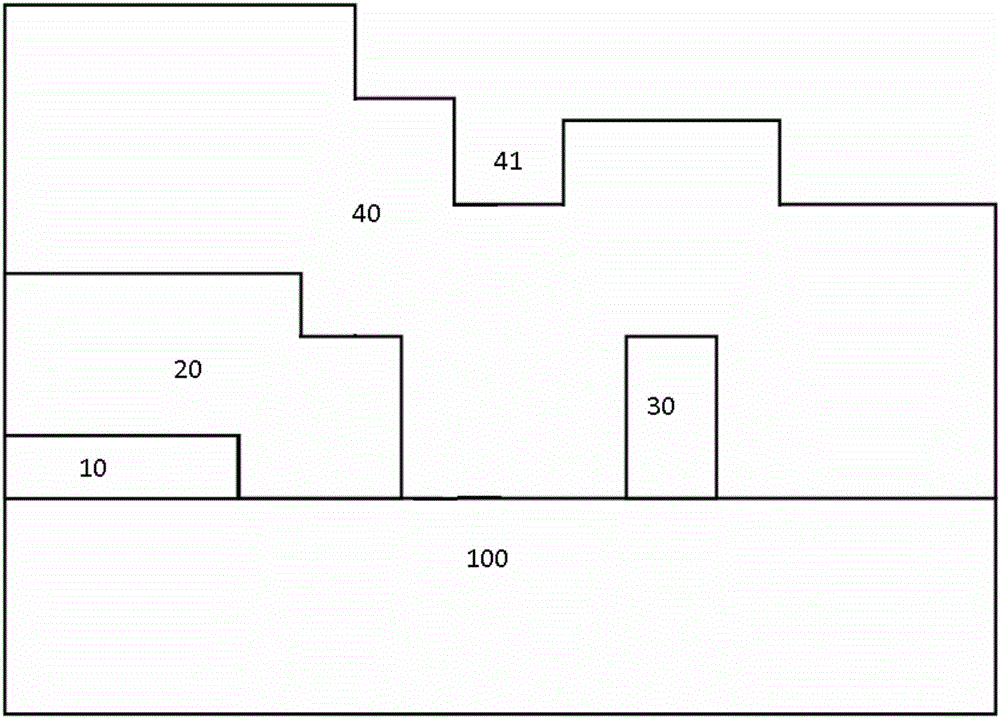

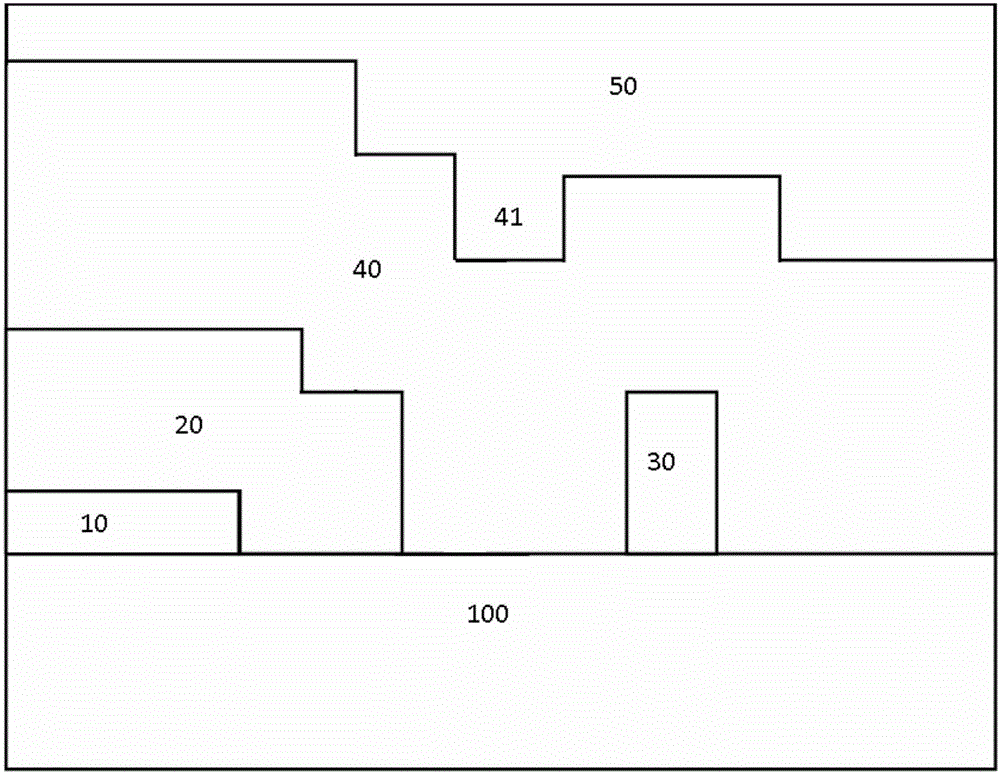

[0036] Figure 1 to Figure 6 Eac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com