Cyclocarya paliurus leaf solid beverage, as well as preparation method and application thereof

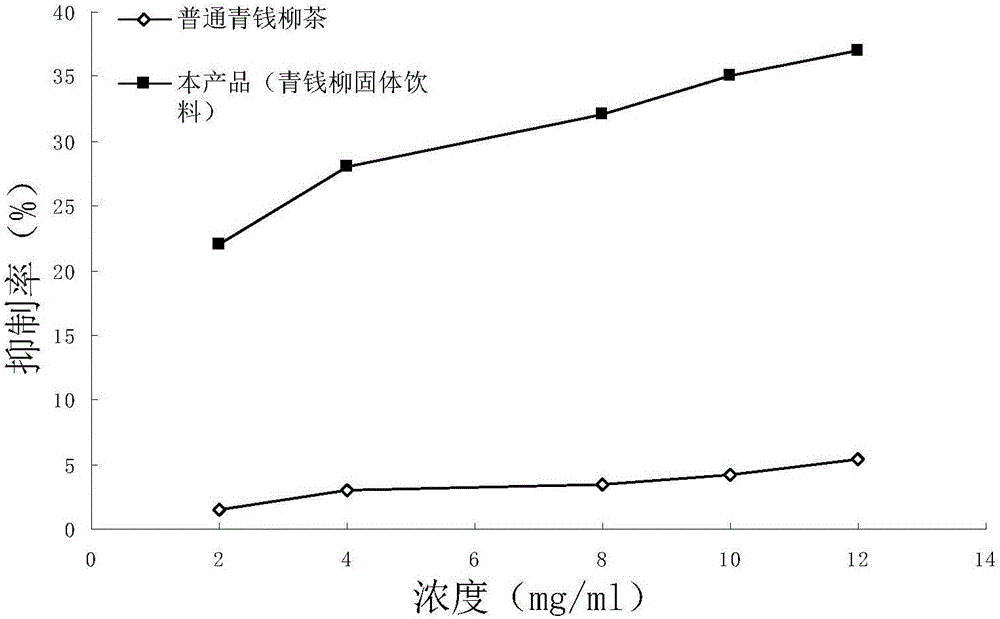

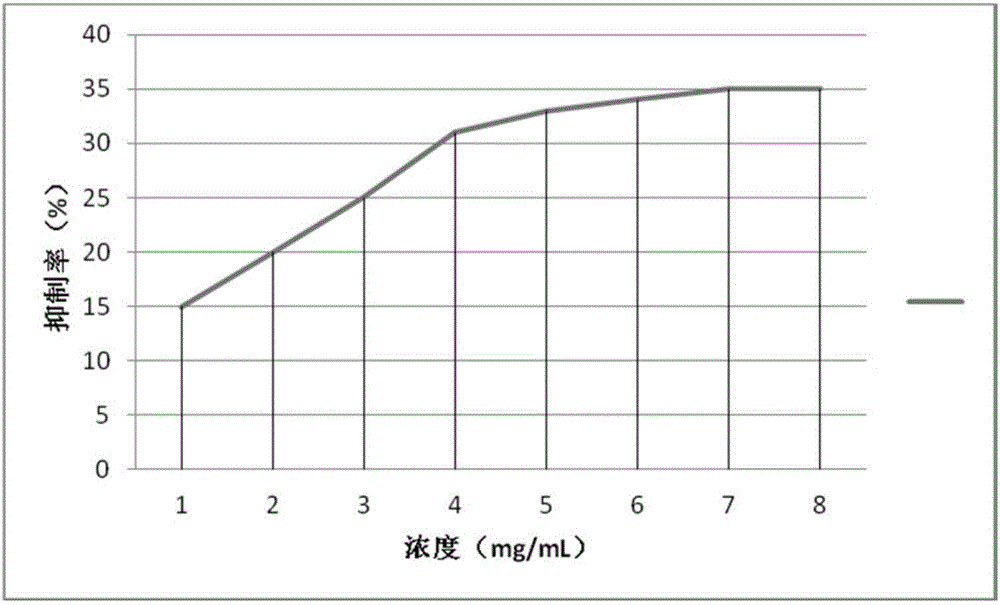

A technology for solid beverages and green buckwheat, applied in food extraction, food science and other directions, can solve the problems of incomplete release of active ingredients, low absorption and utilization rate, waste of valuable resources, etc., and achieves favorable intestinal absorption and high dissolution. , the effect of improving bioavailability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

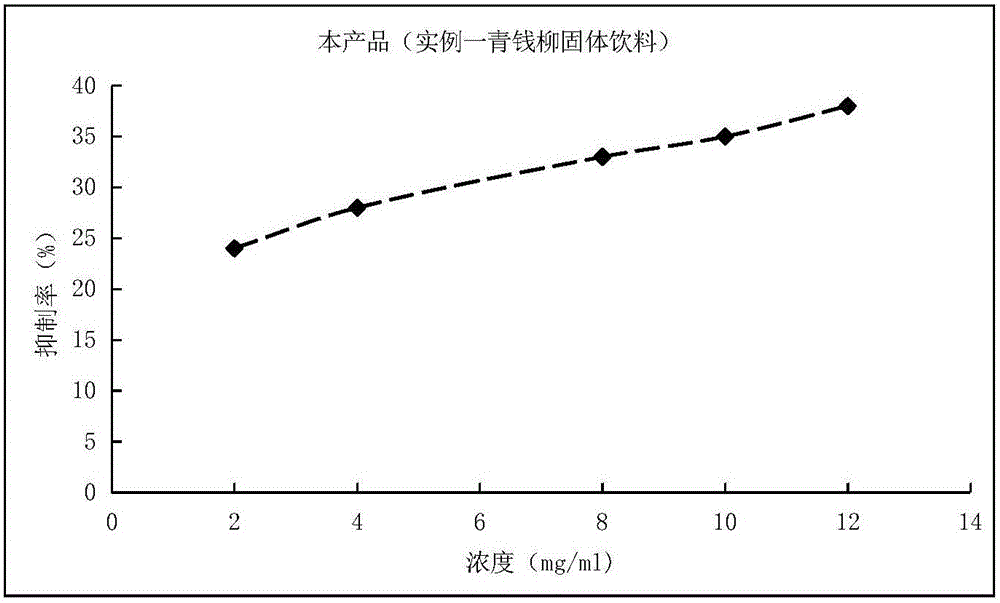

Embodiment 1

[0019] (1) Take the fresh leaves of Cyclocarya paliurus, dry them in a drying box at 65°C for 2 hours, then put the dried leaves of Cyclocarya paliurus into a mechanical pulverizer, and get 200 mesh particles after initial crushing, and then crush them Put into a jet mill, and after jet milling, micro-powder of Cyclocarya paliurus leaves with a particle size ranging from 0.5 to 10 μm is obtained, the temperature of jet milling is 0°C, and the moisture percentage is <6wt.%.

[0020] (2) The leaves of Cyclocarya paliurus are extracted with hot water at 85°C, filtered, and the obtained filtrate is concentrated, alcoholized, deproteinized, and dried to obtain brown-red crude polysaccharides. The crude polysaccharide is formulated into a solution, purified by a macroporous resin, and the obtained solution is concentrated, dialyzed and dried, and the purity of the obtained polysaccharide is 68wt.%.

[0021] (3) Weigh a certain amount of dry powder of Cyclocarya paliurus leaves and e...

Embodiment 2

[0026] (1) Take the fresh leaves of Cyclocarya paliurus, dry them in a drying box at 60°C for 2 hours, then put the dried leaves of Cyclocarya paliurus into a mechanical pulverizer, and obtain 200-mesh particles after initial crushing, and then grind them Put into a jet mill, and after jet milling, the original powder of Cyclocarya paliurus leaves with a particle size ranging from 0.5 μm to 10 μm is obtained. The temperature of jet milling is 0° C., and the moisture percentage is <6 wt.%.

[0027] (2) The leaves of Cyclocarya paliurus are extracted with hot water at 85°C, filtered, and the obtained filtrate is concentrated, alcoholized, deproteinized, and dried to obtain brown-red crude polysaccharides. The crude polysaccharide is formulated into a solution, purified by a macroporous resin, and the obtained solution is concentrated, dialyzed and dried, and the purity of the obtained polysaccharide is 68wt.%.

[0028] (3) Ultrasonic extraction of Cyclocarya paliurus leaf powder...

Embodiment 3

[0031] (1) Take the fresh leaves of Cyclocarya paliurus, dry them in a drying box at 60°C for 2 hours, then put the dried leaves of Cyclocarya paliurus into a mechanical pulverizer, and obtain 200-mesh particles after initial crushing, and then crush them Put into a jet mill, and after jet milling, the original powder of Cyclocarya paliurus leaves with a particle size ranging from 0.5 μm to 10 μm is obtained. The temperature of jet milling is -20° C., and the moisture percentage is <6wt.%.

[0032] (2) The leaves of Cyclocarya paliurus are extracted with hot water at 85°C, filtered, and the obtained filtrate is concentrated, alcoholized, deproteinized, and dried to obtain brown-red crude polysaccharides. The crude polysaccharide is formulated into a solution, purified by a macroporous resin, and the obtained solution is concentrated, dialyzed and dried, and the purity of the obtained polysaccharide is 68wt.%.

[0033] (3) Ultrasonic extraction of Cyclocarya paliurus leaf powde...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

| Purity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com