A method of preparing a polyphosphate composite fertilizer through decomposing phosphate rock with nitric acid

A polyphosphate and compound fertilizer technology, which is applied to ammonium nitrate fertilizers, calcium/strontium/barium nitrates, phosphorus compounds, etc., can solve problems such as high energy consumption, unfavorable energy saving and emission reduction, and strict restrictions, and achieve energy consumption Large, excellent dispersibility, and the effect of increasing the polymerization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

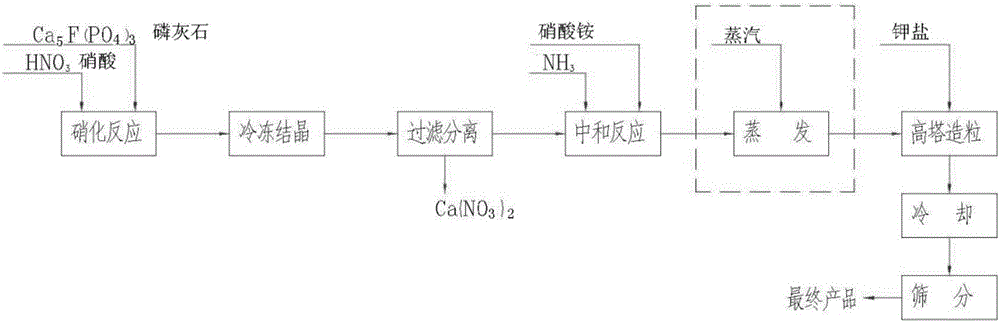

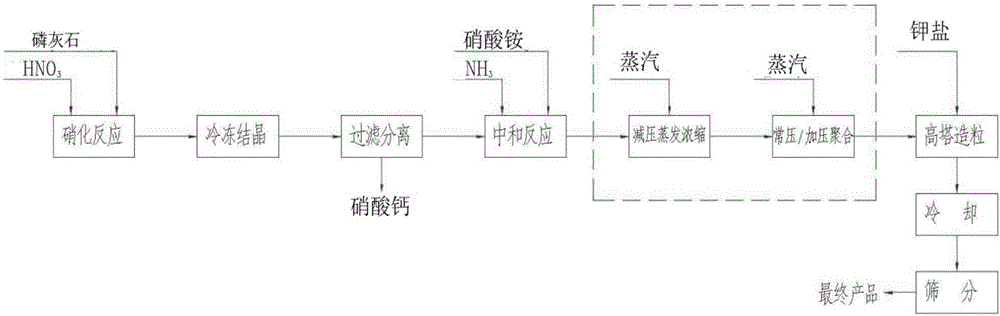

[0024] Such as figure 2 Shown, a kind of method with nitric acid decomposition phosphate rock is prepared to contain polyphosphate compound fertilizer, comprises the following steps:

[0025] (1) Digest 10kg of apatite with 2L of nitric acid with a mass fraction of about 65%;

[0026] (2) crystallization, the crystallization of calcium nitrate is removed by filtration;

[0027] (3) neutralize with 2L ammonia;

[0028] (4) the pressure is reduced to -0.05MPa for evaporation and concentration, until the water content is 2% by weight,

[0029] (5) Pressurize again to more than normal pressure, the reaction temperature is normal temperature, and polymerization reaction takes place to generate polyphosphate.

Embodiment 2

[0031] Such as figure 2 Shown, a kind of method with nitric acid decomposition phosphate rock is prepared to contain polyphosphate compound fertilizer, comprises the following steps:

[0032] (1) Digest 10kg of apatite with 2L of nitric acid with a mass fraction of about 65%;

[0033] (2) crystallization, the crystallization of calcium nitrate is removed by filtration;

[0034] (3) neutralize with 2L ammonia;

[0035] (4) pressure is reduced to-0.05MPa and is evaporated and concentrated to water content and is 2% weight,

[0036] (5) Pressurize again to 102.3KPa, the reaction temperature is 170°C, and react for 1.5 hours to generate polyphosphate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com