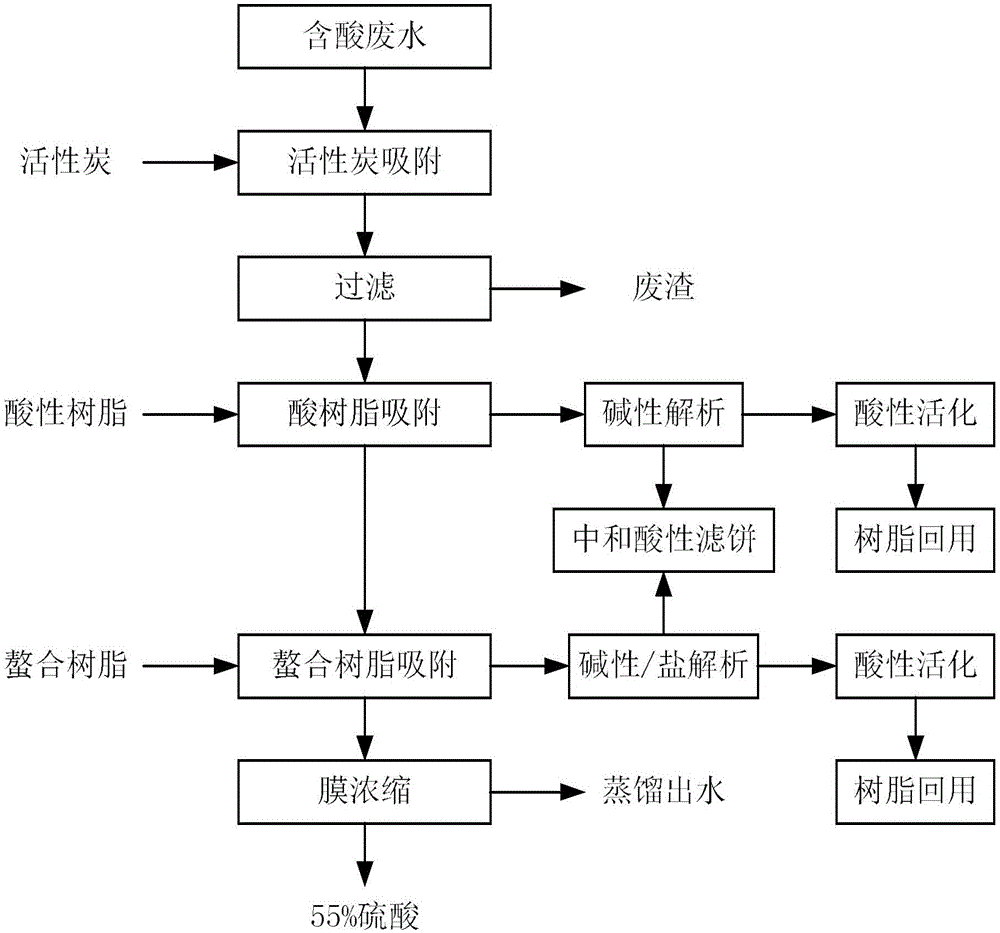

Treatment process of acid-containing wastewater

A technology for treating process and wastewater, applied in the treatment field of acid-containing wastewater from bromo-acid, can solve the problems of high cost, extremely high equipment requirements and high risk, and achieve the effects of mild conditions, reduced production cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] The acid-containing wastewater produced by the production of bromic acid has a sulfuric acid content of 15%, COD=6000mg / L, and ammonia nitrogen 29mg / L.

[0040] (1) Activated carbon adsorption: add 0.2% activated carbon by mass volume fraction to bromic acid-containing wastewater, stir at 55° C. for 1 hour, and filter to obtain a red filtrate. After testing, the o-dichlorobenzene content in the filtrate was 0.01%wt, COD=4500mg / L, ammonia nitrogen was 27mg / L, and the bromide ion concentration was 500ppm.

[0041] (2) Acidic resin adsorption: the filtrate after activated carbon adsorption is adsorbed by acidic resin, and the water outlet speed is 3 times of the resin volume per hour. After testing, the adsorption outlet water shows that COD=30mg / L, ammonia nitrogen is not detected, and the bromide ion concentration is 500ppm.

[0042] (3) Chelating resin adsorption: after the acidic resin is adsorbed, the waste acid water is adsorbed by the chelating resin, and the water ...

Embodiment 2

[0049] The acid-containing wastewater produced by the production of bromic acid has a sulfuric acid content of 10%, COD=6050mg / L, and ammonia nitrogen 27mg / L.

[0050] (1) Activated carbon adsorption: add 0.4% mass volume activated carbon to the acid-containing waste water of bromic acid, stir at 40° C. for 1.5 h, and filter to obtain a red filtrate. After testing, the o-dichlorobenzene content in the filtrate was 0.013%wt, COD=4230mg / L, ammonia nitrogen was 24mg / L, and the bromide ion concentration was 480ppm.

[0051] (2) Acidic resin adsorption: the filtrate after activated carbon adsorption is adsorbed by acidic resin, and the water outlet speed is 2.5 times of the resin volume per hour, and the adsorption water is detected, COD=25mg / L, ammonia nitrogen is not detected, and the bromide ion concentration is 480ppm.

[0052] (3) Chelating resin adsorption: After the acidic resin is adsorbed, the waste acid water is adsorbed by the chelating resin, and the water outlet speed ...

Embodiment 3

[0055] The acid-containing wastewater produced by the production of bromic acid has a sulfuric acid content of 20%, COD=6130mg / L, and ammonia nitrogen 33mg / L.

[0056] (1) Activated carbon adsorption: add 0.2% mass volume activated carbon to the acid-containing wastewater of bromic acid, stir at 70° C. for 0.5 h, and filter to obtain a red filtrate. After testing, the o-dichlorobenzene content in the filtrate was 0.01%wt, COD=4800mg / L, ammonia nitrogen was 31mg / L, and the bromide ion concentration was 510ppm.

[0057] (2) Acidic resin adsorption: the filtrate after activated carbon adsorption is adsorbed by acidic resin, and the water outlet speed is 2 times of the resin volume per hour, and the adsorption water is detected, COD=40mg / L, ammonia nitrogen is not detected, and the bromide ion concentration is 510ppm.

[0058] (3) Chelating resin adsorption: After the acidic resin is adsorbed, the waste acid water is adsorbed by the chelating resin, and the water outlet speed is 4...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com