Novel three-chamber septic tank processed through injection molding and compression molding compounding technology

A composite process and process processing technology, applied in anaerobic digestion treatment, chemical instruments and methods, water/sludge/sewage treatment, etc., can solve the problems of deodorization, heat preservation, poor fermentation effect, septic tank frost heave and rupture, construction Difficulties and other problems, to achieve the effect of flexible site selection, low equipment cost, and shortened construction period

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

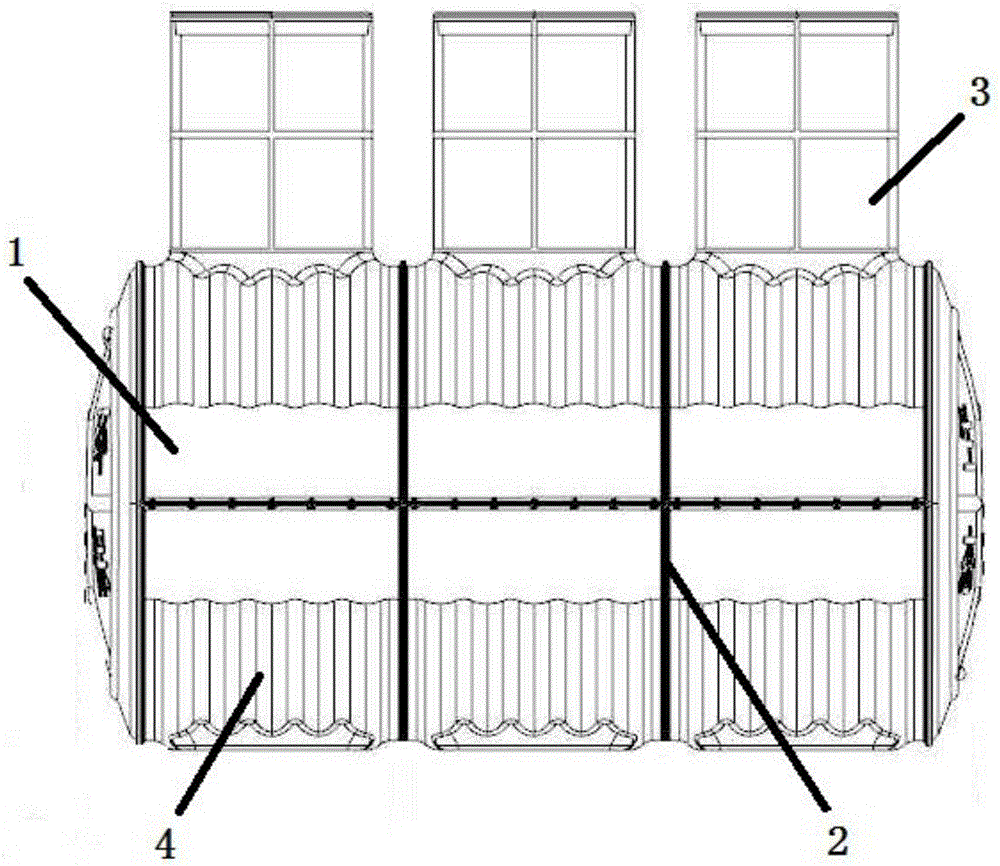

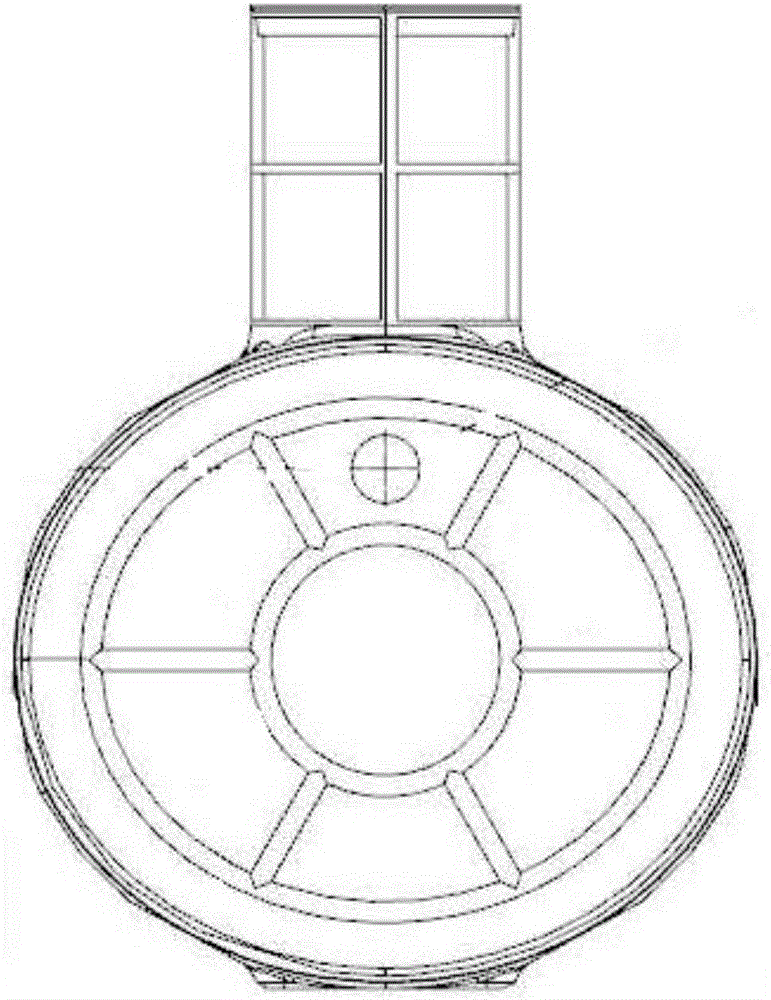

[0022] Such as figure 1 , figure 2 As shown, a novel three-compartment septic tank processed by a composite injection molding and compression molding process includes a septic tank body that is formed by connecting three groups of septic tanks 1 that are independent of each other. The connection of the tank 1 is sealed by an integral sealing strip 2, and the upper part of each group of septic tanks 1 is provided with a cleaning and defecation port 3, and the septic tank 1 is processed by a composite process of injection molding and compression molding; the septic tank 1 The surface or / inner wall is provided with reinforcing ribs 4, and the reinforcing ribs 4 are reinforced with steel wires; the septic tank 1 has an elliptical structure, and the reinforcing ribs 4 are arranged at intervals along the circumferential direction of the septic tank 1 to form The wrapping of the septic tank 1 enhances the overall strength of the septic tank 1. The septic tank 1 is made of wood plast...

Embodiment 2

[0025] Such as figure 1 , figure 2 As shown, a novel three-compartment septic tank processed by a composite injection molding and compression molding process includes a septic tank body that is formed by connecting three groups of septic tanks 1 that are independent of each other. The joint of the tank 1 is sealed by an integrated anti-leakage sealing strip 2. The upper part of each group of septic tanks 1 is provided with a cleaning port 3, and the septic tank 1 is processed by a composite process of injection molding and compression molding; The surface or / inner wall of the septic tank 1 is provided with reinforcing ribs 4, and the reinforcing ribs 4 are equipped with steel wire reinforcement; the septic tank 1 has a cylindrical structure, and the reinforcing ribs 4 extend along the circumference of the septic tank 1. It is arranged at intervals in the direction to form a package for the septic tank 1 and enhance the overall strength of the septic tank 1.

[0026] The septic ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com