Multiple-feeding-port and multiple-seal combined internal and external heating fluidized bed pyrolysis and gasification system

A pyrolysis gasification, internal and external heating technology, applied in the direction of granular/powdered fuel gasification, gasification process, gasification device details, etc., can solve the problems of high calorific value, less tar and pollutant content, and low cost , to achieve the effects of reducing tar content, increasing the level of gas-solid mixing, and increasing the calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

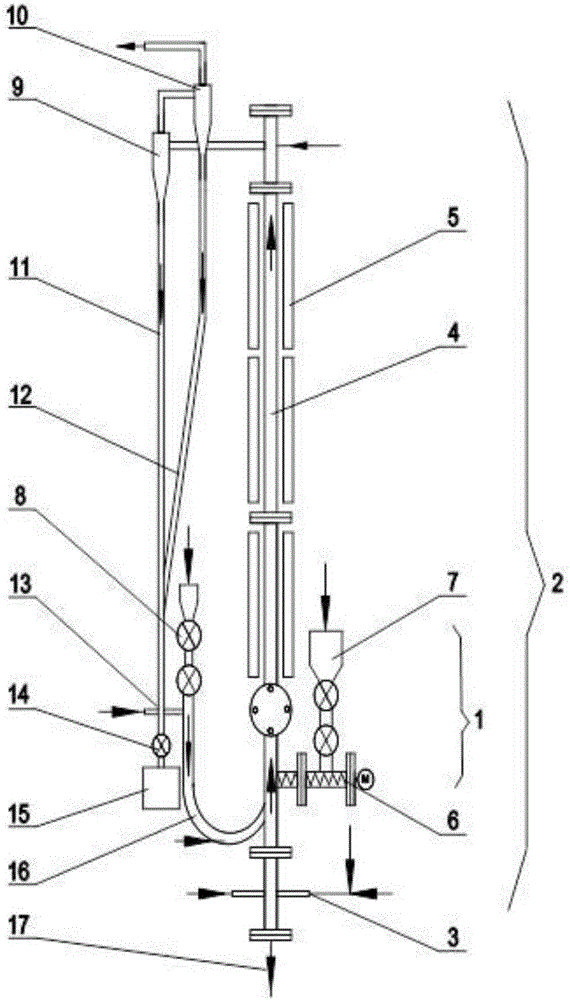

[0026] See figure 1 , the system includes a material feeding unit 1, a fluidized bed pyrolysis gasification unit 2, a cyclone separator, a cyclone separator feeding pipe, a non-mechanical sealing valve 13, a non-mechanical valve circulation return device 16, and a sequentially connected connection. Unloading valve 14 and solid product collection tank 15, the system generates synthesis gas or pyrolysis gas; the fluidized bed pyrolysis gasification unit 2 includes riser 4, riser inlet system 3 and heater 5, riser inlet The gas system 3 is communicated with the riser 4 through a pipeline; the material feeding unit 1 includes a double-valve lock hopper feeder 7, a rotary valve feeder 8, a screw conveyor 6, a double-valve lock hopper feeder 7 and The screw conveyor 6 is communicated and connected, the screw conveyor 6 is communicated with the riser pipe 4, the non-mechanical valve circulation return device 16 is communicated with the riser pipe 4, and the rotary valve feeder 8 is c...

Embodiment 2

[0033] See figure 1 , The difference between this embodiment and Embodiment 1 is: there is a heater 5 outside the riser 4 of the fluidized bed pyrolysis gasification unit 2, the heater 5 is a microwave heater, and the riser 4 housing is made of ceramics or quartz The pipe material is suitable for microwave pyrolysis and gasification; the double-valve lock hopper feeder 7 and the screw conveyor 6 of the material feeding unit 1 directly transport agricultural and forestry waste (such as orange stalks, etc.) to the riser 4, and the rotary valve feeds The feeder 8 adds the discarded iron rust to the recycling device 16 . Other system components are the same as in Embodiment 1.

Embodiment 3

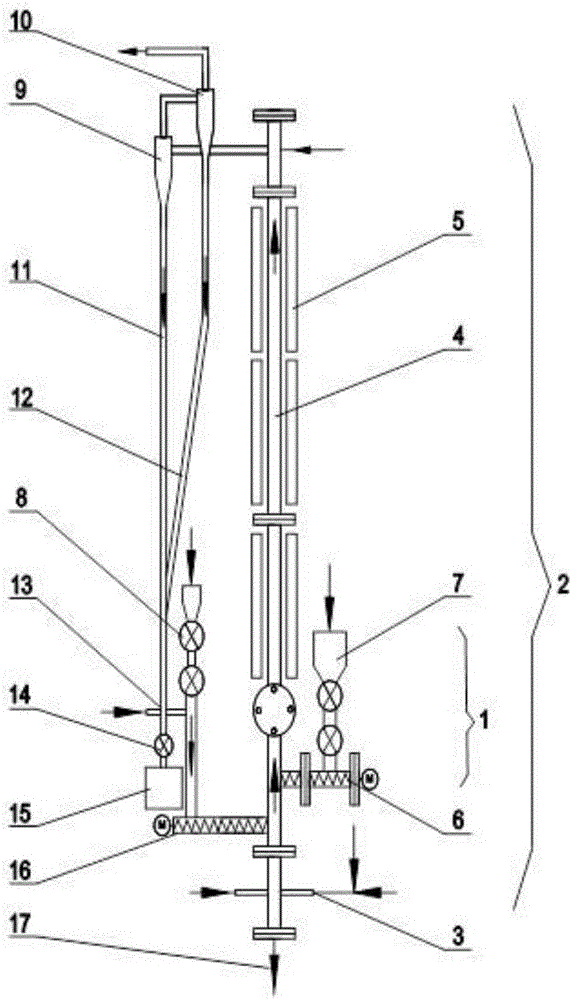

[0035] See figure 2 The difference between this embodiment and Embodiment 1 is that there is a heater 5 outside the riser 4 of the fluidized bed pyrolysis gasification unit 2, the heater 5 is an electric heater, and the riser 4 housing is made of carbon steel or Stainless steel or other heat-resistant steel. An L-shaped non-mechanical seal valve 13 and a screw conveying extrusion type circulation return device 16 are used between the riser 4 and the discharge pipe of the cyclone separator to realize multi-seal combination to ensure that the riser 4 and the discharge pipe 11 and There is no cross-gas between 12. Other system components are the same as in Embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com