Technique of utilizing gasified coal gas and coke oven gas to co-produce liquefied natural gas, methanol and liquid ammonia

A technology of liquefied natural gas and coke oven gas, which is applied in the field of coal chemical industry, can solve the problems that components cannot be fully utilized, can only be used as fuel, and poor adjustability, etc., to achieve maximum utilization, ensure feasibility, and ensure purity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0081] The composition of typical coke oven gas is shown in Table 1, the pressure is 1-5kPa(G), the temperature is about 40°C, and the flow rate is 34000Nm3 / h.

[0082] Table 1 Volume composition of coke oven gas

[0083] H2

CO

CO2

CH4

cHm

N2

53.82

10.74

4.68

22.57

3.15

4.63

O2

H2S

total

tar and dust

0.41

trace

100

trace

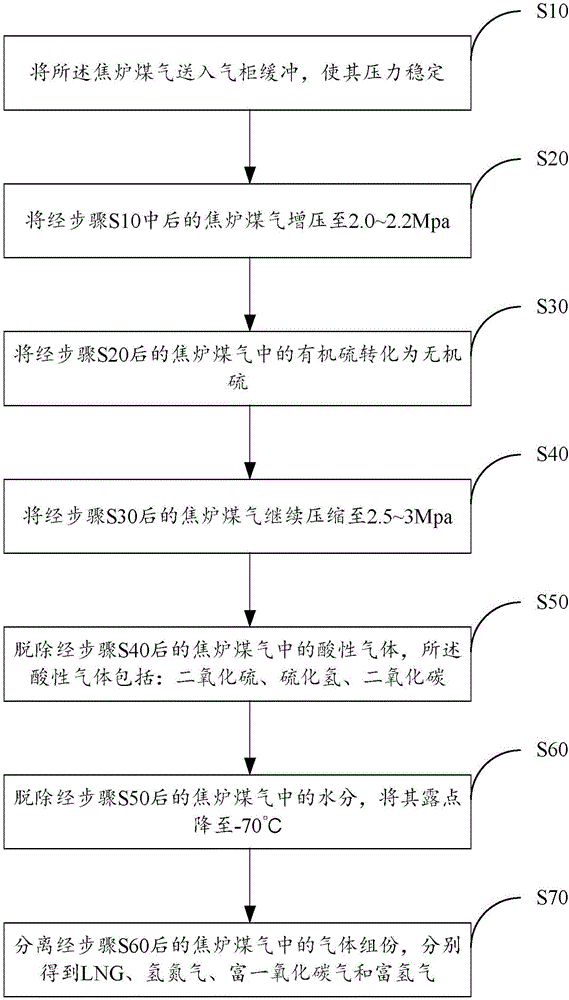

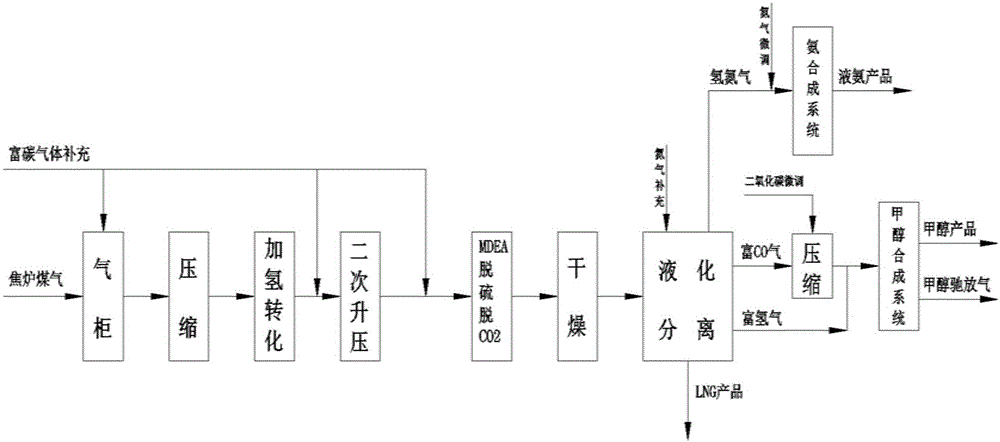

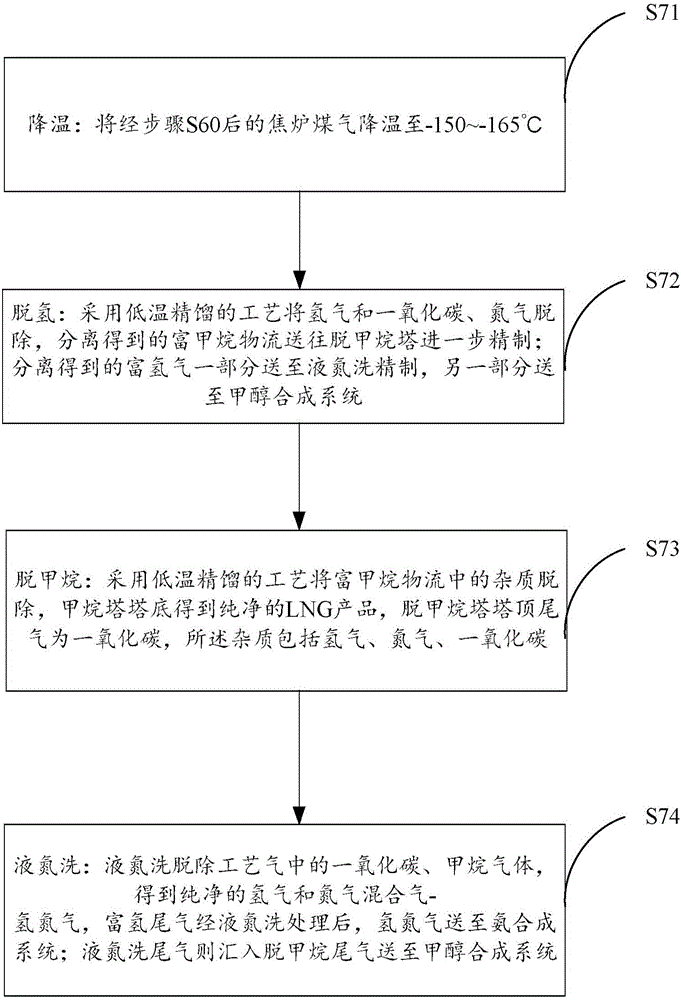

saturation

[0084] Such as figure 1 In the process shown, the coke oven gas is first sent to the gas tank for buffering, and after the pressure is stabilized, the compressor is used to pressurize it to about 2.0MPa for hydrogenation and conversion treatment, and then the second step-up is carried out to 2.8MPa, and then sent to MDEA for desulfurization and desulfurization The carbon plant is purified, and then sent to the drying device to remove moisture, and then sent to the cryogenic liquefaction separation device for deep separation, and e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com