Gas-phase concentration type triethylene glycol dehydration regeneration system

A technology of regeneration system and triethylene glycol, which is applied in the direction of gas fuel, petroleum industry, fuel, etc., can solve the problems that the regeneration gas cannot enter the low-pressure discharge system, does not meet the requirements of environmental protection and safety, and cannot be used as fuel, etc., and achieves an increase in concentration , Improve the effect of flash evaporation and reduce the water content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] In order to better understand the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

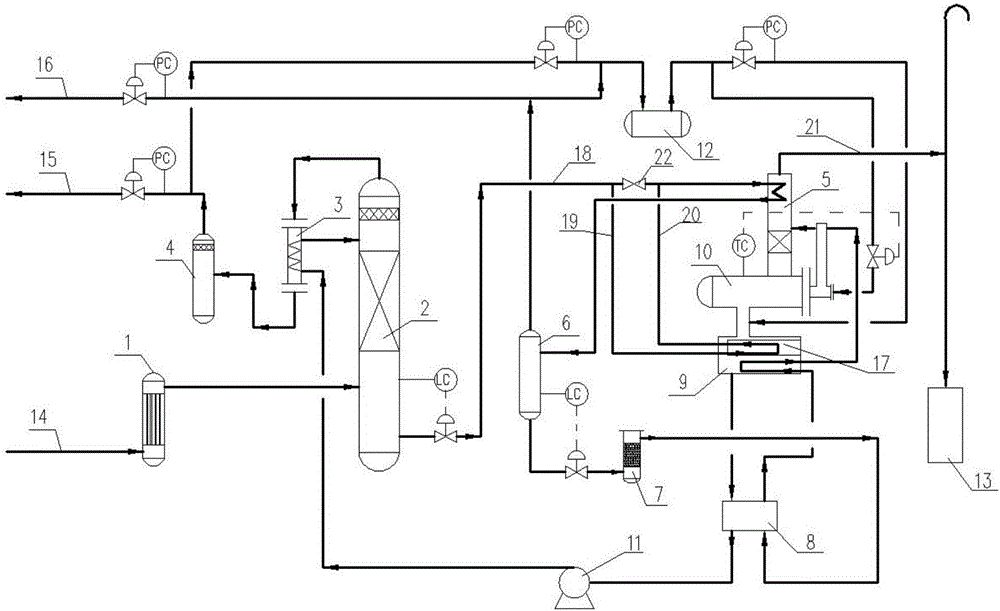

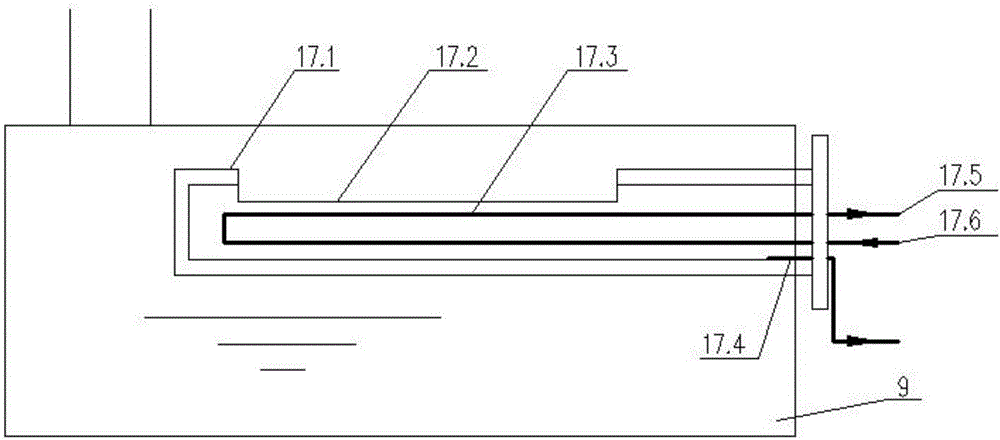

[0018] Such as figure 1 A gas phase enrichment type triethylene glycol dehydration regeneration system shown includes a product gas separator 4, a gas lean liquid heat exchanger 3, a coalescence filter separator 1, an absorption tower 2, a rectification column 5, and a flash tank 6. Filter 7, lean-rich liquid heat exchanger 8, lean liquid buffer tank 9, reboiler 10, gas lean liquid heat exchanger 3, circulation pump 11, fuel gas buffer tank 12, wherein the flash tank 6 includes Feed inlet, flash gas outlet and triethylene glycol-rich outlet; rectification column 5 includes regeneration gas outlet, feed inlet, hot gas inlet and material outlet; reboiler 10 includes fuel gas inlet, feed inlet, triglyceride-poor alcohol outlet and hot gas outlet; the absorption tower 2 includes a poor triethyle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com