Biodegradable liquid special for micro emulsion type wire cutting and preparation method of biodegradable liquid

A technology of biodegradation and wire cutting, which is applied in the direction of lubricating composition and petroleum industry, etc. It can solve the problems of oily finish of the processed workpiece, serious pollution of the working environment, environmental pollution of wire cutting fluid, etc., and achieve good separation and sedimentation, cleanability Good, low-cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] An easily biodegradable microemulsion special liquid for wire cutting, which is composed of the following raw materials in weight percentage: Component A: 15-35%, Component B: 8-15%, Component C: 7-13%, Component D: 7-13%, Component E: 6-11%, Component F: 5-10%, Component G: 2-5%, Component H: 2-5%, Component I: 1 -3%, Component J: 1-3%, Component K: 25-40%, of which:

[0028] Component A is one or more of rubber oil, transformer oil, No. 15 white oil, and liquid paraffin;

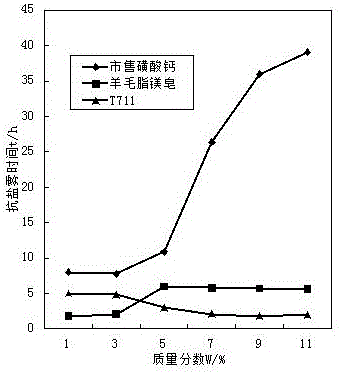

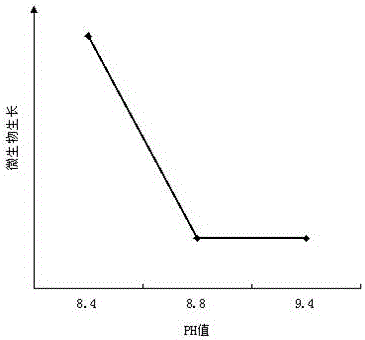

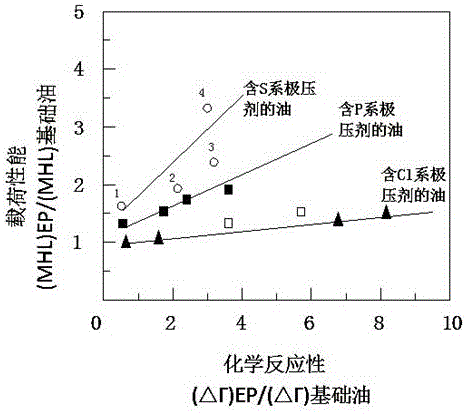

[0029] Component B is dodecenylsuccinic acid, octadecylamine N-oleoyl acid, barium sulfonate, benzotriazole, barium dinonyl naphthalene sulfonate, organic phosphate, borate, sulfonate One or more of calcium phosphate and magnesium lanolin soap;

[0030] Component C is one or more of sorbitan fatty acid esters, polyoxyethylene fatty alcohol ethers, imidazole-type compounds, betaine-type surfactants, and nonylphenol polyoxyethylene ethers;

[0031] Component D is one or more of polyethylene glycol ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| pour point | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com