How to prepare malt vinegar

A malt and acetic acid fermentation technology, which is applied in the preparation of malt vinegar and the field of malt vinegar, can solve the problems of poor taste and complicated process of malt vinegar, and achieve the effect of outstanding characteristic taste, strong sour taste and rich nutrition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

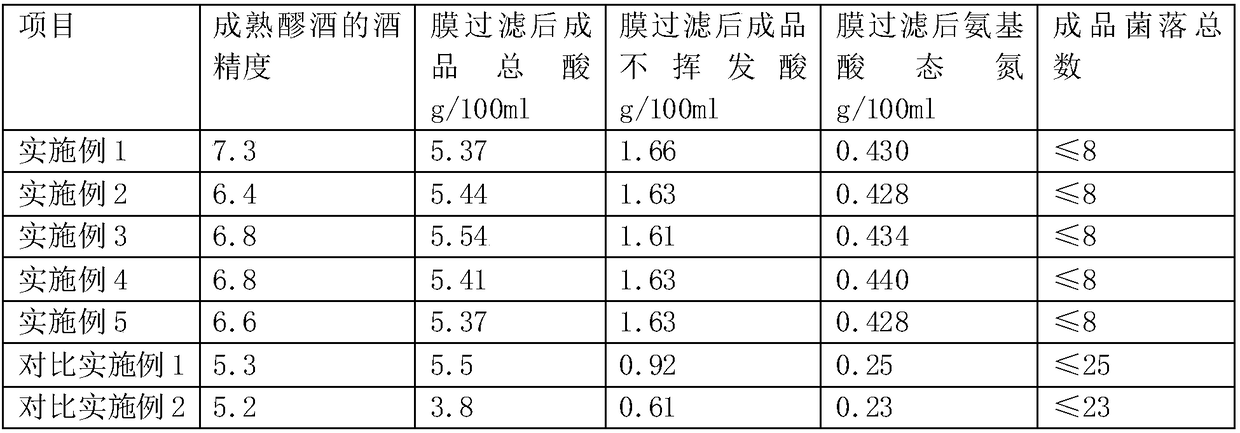

Examples

Embodiment 1

[0027] Embodiment 1 (with malt and cornmeal as raw material, feeding base is every batch of 1500kg)

[0028] The preparation method of malt vinegar comprises the following steps:

[0029] A. The preparation process of grain malt: first soak the wheat for 12 hours, then germinate the soaked wheat at 36°C, water it every 8 hours during the germination process, and pour it thoroughly with running water. The length of the malt is 1.2- 1.8cm, with a germination rate of 70-90%, you can get wheat malt, crush it, and set aside;

[0030] B. Blending process: mix 429 kg of broken malt with 1071 kg of cornmeal and 5355 kg of water to obtain a mixed slurry, then add bran koji to the mixed slurry and mix evenly to obtain a slurry mash for subsequent use, wherein Aspergillus niger As3.758 As a result of koji making, the activity of glucoamylase in bran koji ≥ 800μ; the mass ratio of bran koji to mixed slurry is 0.08:1;

[0031] C. Saccharification and alcoholic fermentation process: put t...

Embodiment 2

[0038] Embodiment 2 (with malt and cornmeal as raw material, feeding base is every batch of 1500kg)

[0039] The preparation method of malt vinegar comprises the following steps:

[0040]A. The preparation process of grain malt: first soak the barley for 13 hours, then germinate the soaked wheat at 37°C, water it every 9 hours during the germination process, and pour it thoroughly with running water. The length of the malt is 1.2- 1.8cm, with a germination rate of 70-90%, you can get barley malt, smash it, and set aside;

[0041] B. Slurry mixing process: mix 500kg of broken malt with 1000kg of cornmeal and 6000kg of water to obtain a mixed slurry, then add bran koji to the mixed slurry and mix evenly to obtain a slurry mash for subsequent use, wherein Aspergillus niger As3.758 As a result of koji making, the activity of glucoamylase in bran koji ≥ 800μ; the mass ratio of bran koji to mixed slurry is 0.12:1;

[0042] C. Saccharification and alcoholic fermentation process: pu...

Embodiment 3

[0049] Embodiment 3 (with malt and corn flour as raw material, feeding base is every batch of 1500kg)

[0050] The preparation method of malt vinegar comprises the following steps:

[0051] A. The preparation process of grain malt: Soak the buckwheat for 11 hours, then germinate the soaked wheat at 39°C, water it every 7 hours during the germination process, and pour it thoroughly with running water. The length of the malt is 1.2- 1.8cm, with a germination rate of 70-90%, you can get buckwheat malt, crush it and set aside;

[0052] B. Slurry mixing process: mix 466kg of broken malt with 1034kg of cornmeal and 5687kg of water to obtain a mixed slurry, then add bran koji to the mixed slurry and mix evenly to obtain a slurry mash for subsequent use, wherein Aspergillus niger As3.758 As a result of koji making, the activity of glucoamylase in bran koji ≥ 800μ; the mass ratio of bran koji to mixed slurry is 0.09:1;

[0053] C. Saccharification and alcoholic fermentation process: ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com