Method for producing L-malic acid through aspergillus oryzae fermentation

A technology of Aspergillus oryzae and malic acid, applied in the field of fermentation, can solve the problems of difficult fermentation process and difficult industrial production, and achieve the effect of simple medium composition, low cost, simple and easy control of fermentation conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0018] Example 1 Effect of different carbon sources on the production of L-malic acid by Aspergillus oryzae

[0019] The medium used, in g / L: add 120 glucose, starch, maltose, fructose and lactose as carbon sources, 3 soybean peptone, 0.15 KH 2 PO 4 , 0.15K 2 HPO 4 , 0.10 MgSO 4 ·7H 2 O, 0.10 CaCl 2 ·H 2 O, 0.05 NaCl, 0.01 citric acid, 0.005 FeSO 4 ·7H 2 O, 60 CaCO 3 , pH natural. Ferment for 120 hours at a temperature of 30° C. and a rotating speed of 200 r / min. The results are shown in Table 1. It can be seen from Table 1 that, except for lactose, all kinds of sugars can be used as a good carbon source, and glucose as a carbon source has the highest acid production.

[0020] Table 1 Effect of different carbon sources on the production of L-malic acid by Aspergillus oryzae

[0021] Type of carbon source

Embodiment 2

[0022] Example 2 Effects of different nitrogen sources on the production of L-malic acid by Aspergillus oryzae

[0023] The medium used, in g / L: add 3 tryptone, soybean peptone, urea, ammonium sulfate, corn steep liquor and soybean cake powder as nitrogen sources, 120 glucose, 0.15 KH 2 PO 4 , 0.15K 2 HPO 4 , 0.10 MgSO 4 ·7H 2 O, 0.10CaCl 2 ·H 2 O, 0.05 NaCl, 0.01 citric acid, 0.005 FeSO 4 ·7H 2 O, 60 CaCO 3 , pH natural. Ferment for 120 hours at a temperature of 30° C. and a rotating speed of 200 r / min. The results are shown in Table 2. It can be seen from Table 2 that the effect of using tryptone and soybean peptone is better, and the effect of using tryptone as a nitrogen source is the best.

[0024] Table 2 Effects of different nitrogen sources on the production of L-malic acid by Aspergillus oryzae

[0025] Type of nitrogen source

Embodiment 3

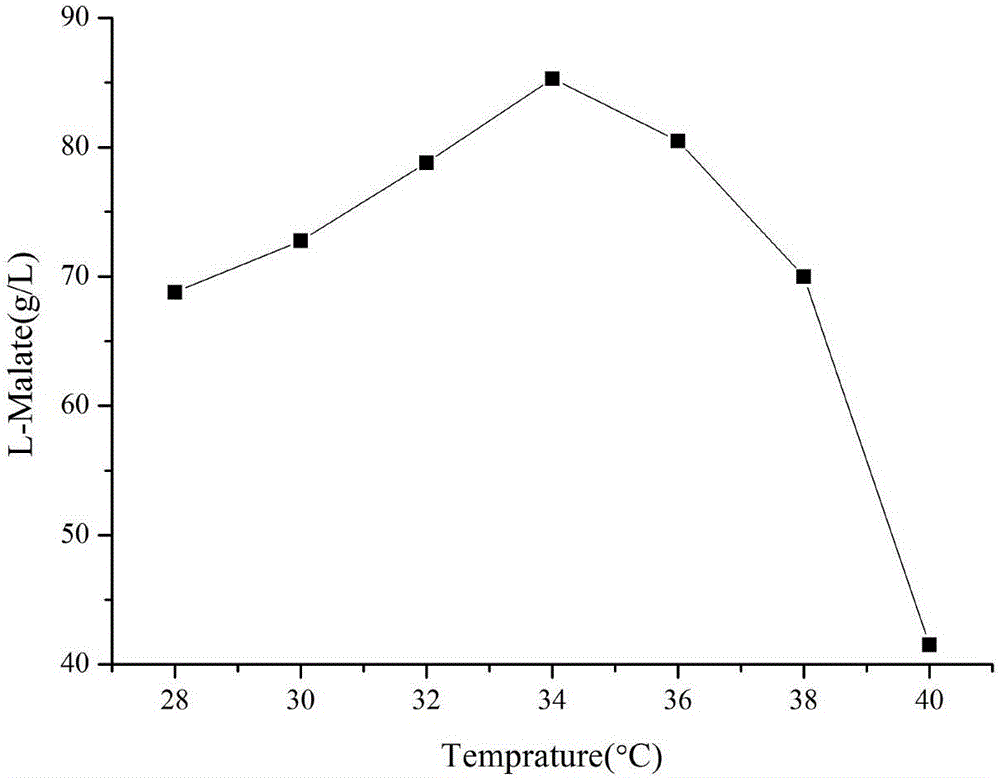

[0026] Example 3 Effects of different temperatures on the production of L-malic acid produced by Aspergillus oryzae

[0027] The medium used, in g / L: 120 glucose, 3 tryptone, 0.15 KH 2 PO 4 , 0.15K 2 HPO 4 , 0.10MgSO 4 ·7H 2 O, 0.10 CaCl 2 ·H 2 O, 0.05 NaCl, 0.01 citric acid, 0.005 FeSO 4 ·7H 2 O, 60 CaCO 3 , pH natural. Set the temperature as 28°C, 30°C, 32°C, 34°C, 36°C, 38°C, 40°C respectively. Under the rotating speed of 200r / min, ferment for 120h. result figure 1 shown. Depend on figure 1 It can be seen that the yield of L-malic acid increases with the increase of temperature before the temperature is 34°C, and the temperature begins to decrease at 36°C, so the optimum fermentation temperature is selected as 34°C.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com