Smelting method for controlling existing form of boron in steel

A smelting method and form technology, applied in the field of smelting to control the form of boron in steel, can solve the problems of lack of form, low proportion of solid solution boron, etc., to reduce vacuum process, reduce boron oxides and nitrides The effect of generating and reducing oxidation burning loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

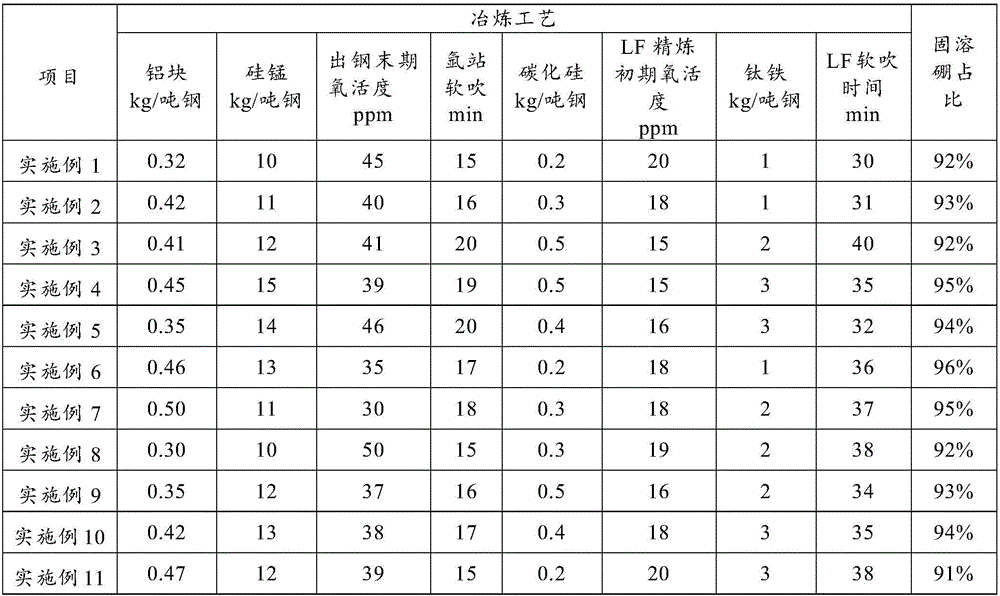

Examples

Embodiment Construction

[0036] The embodiment of the present application provides a smelting method for controlling the form of boron in the steel to solve the technical problems of the low proportion of solid-solution boron in the boron microalloy steel in the prior art and the lack of an effective method for controlling its form; The technical effect of controlling oxygen and nitrogen fixation and increasing the proportion of solid solution boron.

[0037] In order to solve the above technical problems, the general idea of the technical solution provided by the embodiment of the present application is as follows:

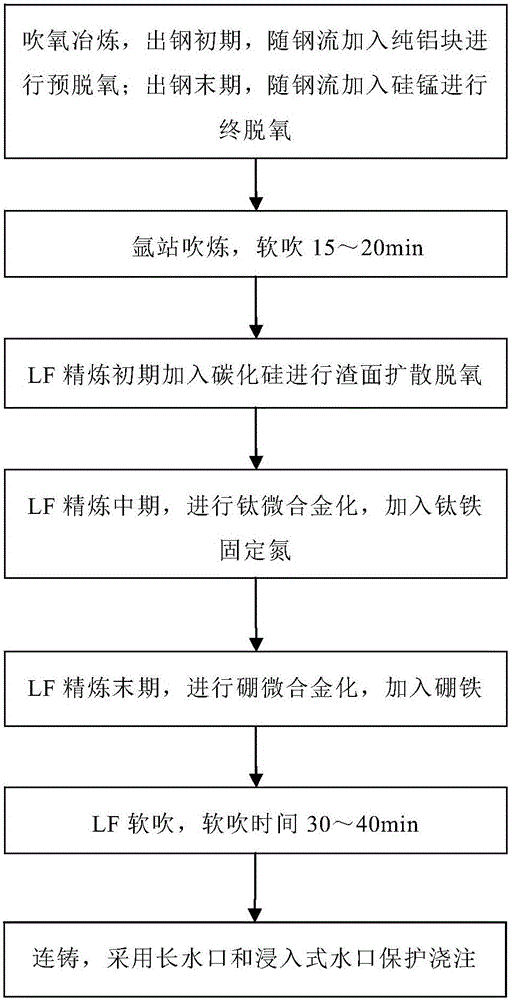

[0038] A smelting method for controlling the form of boron in steel, comprising the following steps:

[0039] Oxygen blowing smelting, at the beginning of tapping, pure aluminum block is added along with the steel stream for pre-deoxidation; at the end of tapping, silicon-manganese is added along with the steel stream for final deoxidation;

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com