Technical process for preparing 5N dysprosium through extraction and separation method

A technology of process flow and separation method, applied in the field of rare earth separation in solvent extraction, can solve problems such as the level of 5N not yet reached, and achieve the effects of large production scale, easy operation and high yield of dysprosium products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

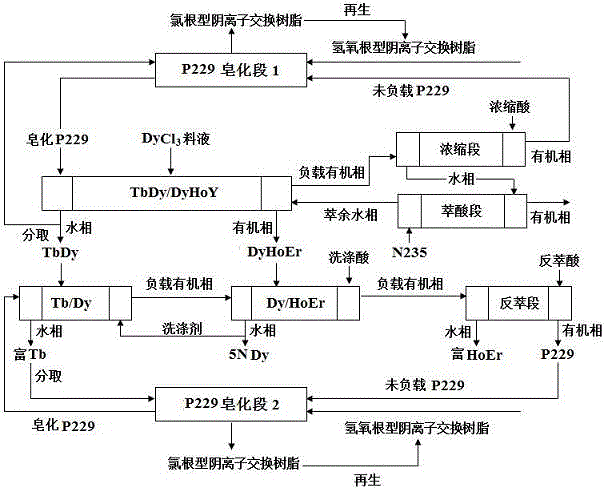

Image

Examples

Embodiment 1

[0037] 1) TbDy / DyHoY separation section

[0038] The first step is the TbDy / DyHoY full-load fractionation extraction separation section to realize the separation of TbDy / DyHoY. The P229 rare earth saponified organic phase with a saponification rate of 0.36 from the fourth step enters from the first stage of the TbDy / DyHoY full-load fractionation extraction system, the rare earth concentration is 1.0mol / L, the ratio of the molar concentration of dysprosium to the molar concentration of rare earth is 0.999, and the pH The dysprosium chloride feed solution with a value of 3 enters from the 22nd stage of the TbDy / DyHoY full-load fractionation extraction system, and the raffinate aqueous dysprosium chloride, holmium, and yttrium solution from the third step acid extraction section enters the TbDy / DyHoY from the 36th stage as a detergent. DyHoY fully loaded fractional distillation extraction system. The TbDy feed liquid is obtained from the first-stage raffinate aqueous phase of th...

Embodiment 2

[0059] 1) TbDy / DyHoY separation section

[0060]The first step is the TbDy / DyHoY full-load fractionation extraction separation section to realize the separation of TbDy / DyHoY. The P229 rare earth saponification organic phase with a saponification rate of 0.36 from the fourth step enters from the first stage of the TbDy / DyHoY full-load fractionation extraction system, the rare earth concentration is 0.5mol / L, the ratio of the molar concentration of dysprosium to the molar concentration of rare earth is 0.9995, and the pH The dysprosium chloride feed solution with a value of 4 enters from the 22nd stage of the TbDy / DyHoY full-load fractionation extraction system, and the raffinate aqueous dysprosium chloride, holmium, and yttrium solution from the third step acid extraction section enters the TbDy / DyHoY from the 34th stage as a detergent. DyHoY fully loaded fractional distillation extraction system. The TbDy feed liquid is obtained from the first-stage raffinate aqueous phase o...

Embodiment 3

[0081] 1) TbDy / DyHoY separation section

[0082] The first step is the TbDy / DyHoY full-load fractionation extraction separation section to realize the separation of TbDy / DyHoY. The P229 rare earth saponified organic phase with a saponification rate of 0.36 from the fourth step enters from the first stage of the TbDy / DyHoY full-load fractionation extraction system, the rare earth concentration is 1.5mol / L, the ratio of the molar concentration of dysprosium to the molar concentration of rare earth is 0.995, and the pH The dysprosium chloride feed solution with a value of 2 enters from the 27th stage of the TbDy / DyHoY full-load fractionation extraction system, and the raffinate aqueous dysprosium chloride, holmium, and yttrium solution from the third step acid extraction section enters the TbDy / DyHoY from the 45th stage as a detergent. DyHoY fully loaded fractional distillation extraction system. The TbDy feed liquid is obtained from the first-stage raffinate aqueous phase of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com