Spontaneous combustion type energy conservation and environmental protection garbage processing system

An energy-saving, environmental-friendly, treatment-system technology, applied in combustion methods, combustion types, lighting and heating equipment, etc., can solve problems such as energy waste, flue gas environmental pollution, etc., achieve a wide range of treatment, simple maintenance, and small footprint Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

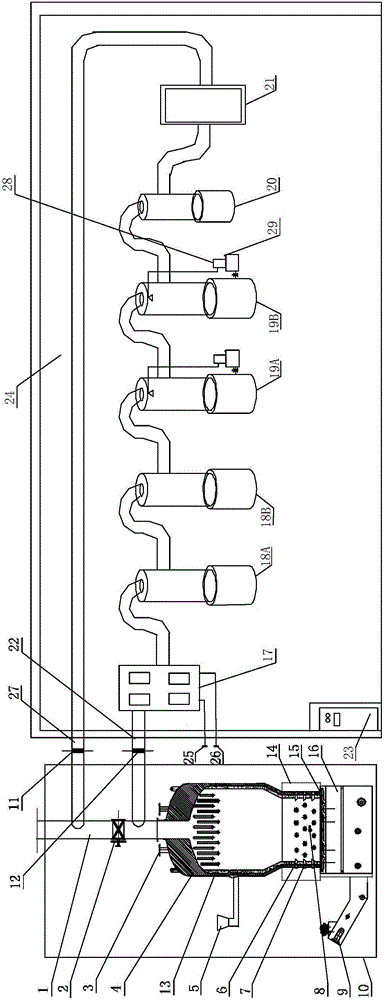

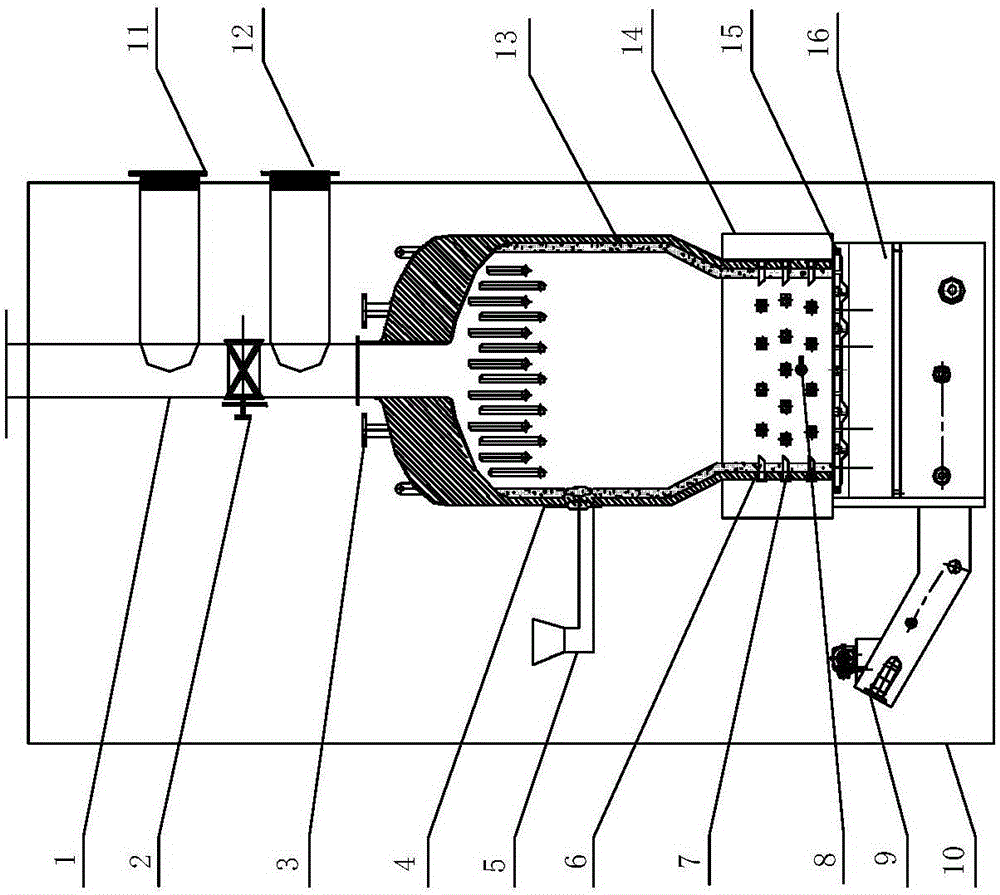

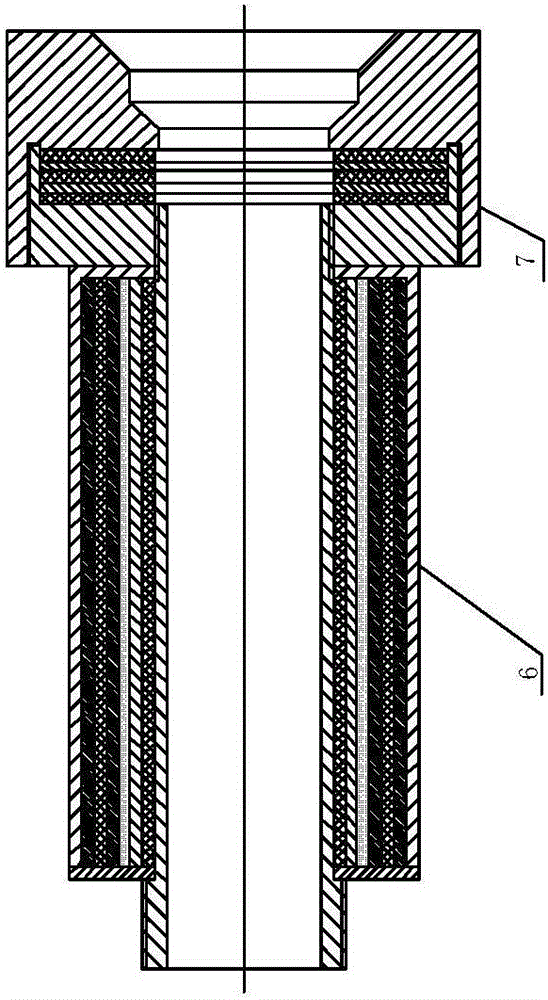

[0028] Example 1, see Figure 1-Figure 6, a self-igniting garbage energy-saving and environmental protection treatment system, including a self-energy garbage incinerator and a mobile flue gas treatment integrated box arranged in the mobile box body 10, and the mobile flue gas treatment integrated box includes a set in the integrated box body 24 The heat exchange type flue gas processor 17, dust processor, decomposer, adsorption tower 20, pipeline, blast system 21 and electric control system 23 inside are equipped with heat exchange type flue gas treatment on one side of the integrated box. The air inlet flange connection port 22 communicated with the device and the air outlet flange connection port 27 communicated with the blower system 21 through pipelines. The self-energy type garbage incinerator includes a furnace body 4, a chimney 1 arranged on the top of the furnace body, a cooling water circulation system 3, a garbage feeding device 5 connected to one side of the furnac...

Embodiment 2

[0034] Example 2, see Figure 7 , in this embodiment, the structure of the self-energy waste incinerator of the self-ignition waste energy-saving and environmental protection treatment system is the same as that of Embodiment 1, and the mobile flue gas treatment integration box includes a heat exchange type Flue gas processor 17, first dust processor 18A, first decomposer 19A, second decomposer 19B, first adsorption tower 20A, second adsorption tower 20B, blast system 21 and electric control system 23. One side of the heat exchange flue gas processor is connected with an inlet flange connection port 22 extending out of the box, and the cooling water inlet 25 and the hot water outlet are respectively connected to the bottom of the heat exchange flue gas processor through circulating water pipes 26. The heat exchange type flue gas processor is connected to the first dust processor 18A through the pipeline, and the first dust processor 18A is connected to the first cracker 19A t...

Embodiment 3

[0035] Example 3, see Figure 8 , in this embodiment, the structure of the self-energy waste incinerator of the self-ignition waste energy-saving and environmental protection treatment system is the same as that of Embodiment 1, and the mobile flue gas treatment integration box includes a heat exchange type Flue gas processor 17 , first decomposer 19A, second decomposer 19B, first adsorption tower 20A, second adsorption tower 20B, blast system 21 and electric control system 23 . One side of the heat exchange flue gas processor is connected with an inlet flange connection port 22 extending out of the box, and the bottom of the heat exchange flue gas processor is connected to the cooling water inlet 9 and the hot water outlet respectively through the circulating water pipe 12. The water outlet 10, the heat exchange type flue gas processor is connected to the first decomposer 19A and the second decomposer 19B through the pipeline, and the second decomposer is connected to the fir...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap