Protein pretreatment and polypeptide high-pH reverse-phase gradation-integrated proteome reactor and application thereof

A proteome and reactor technology, applied in the field of qualitative and quantitative proteomics, can solve problems such as unfavorable hydrophobic protein dissolution and extraction, sample loss, failure to achieve high pH reversed-phase classification of peptides, etc., to improve quantitative analysis. Accuracy, automation, and large-scale identification

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

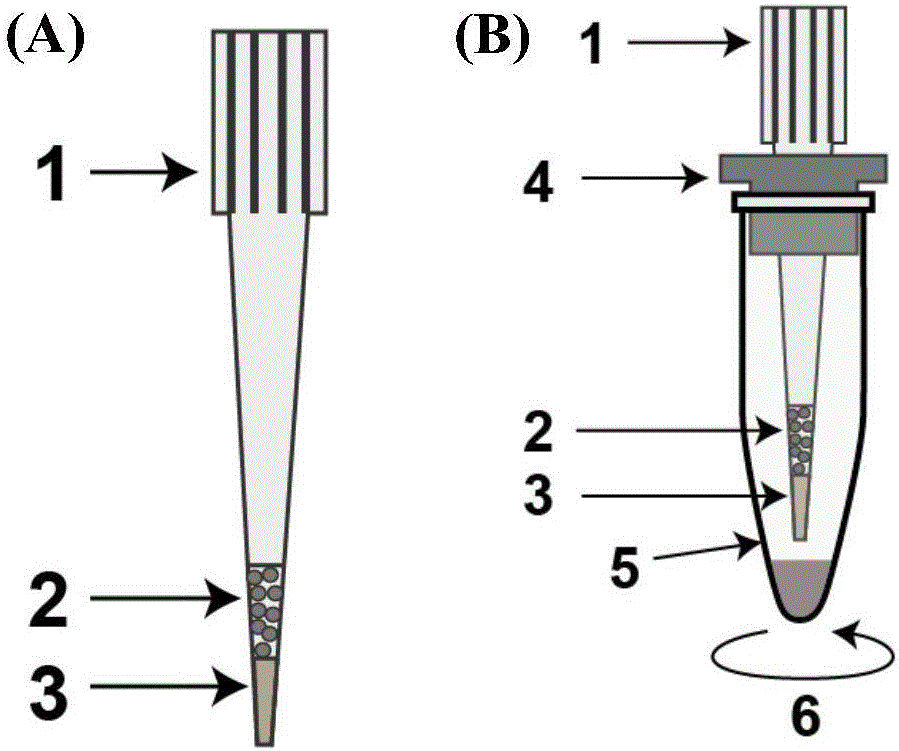

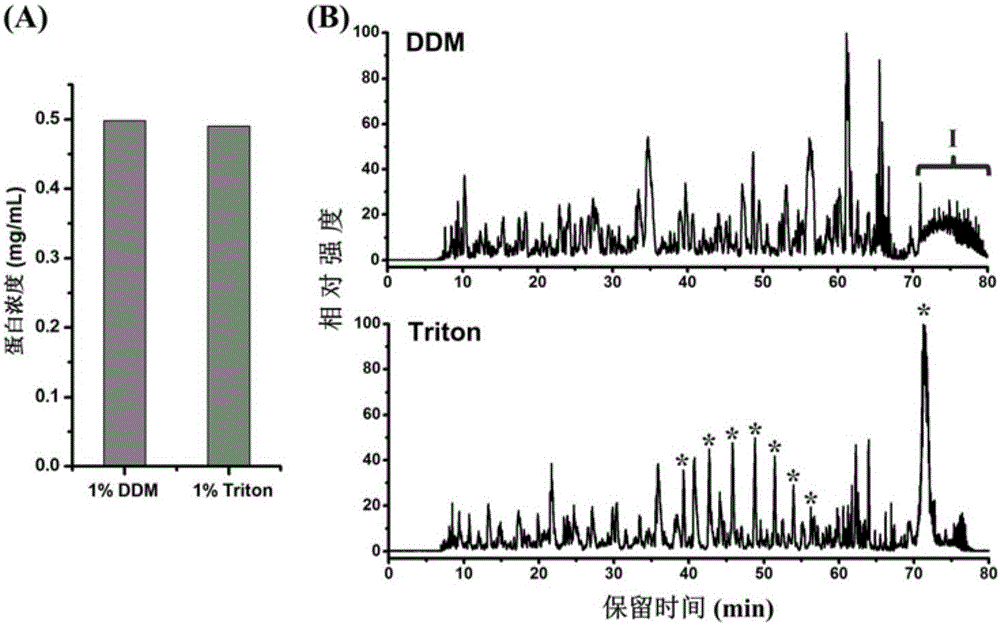

[0059] Such as figure 1 As shown in (A) and (B), a proteomic reactor integrating protein pretreatment and high-pH reverse phase fractionation of peptides, including pipette tip 1, strong cation exchange resin filler 2 and C 18 膜3。 Film 3. Among them, pipette tip 1 is a standard 200μL tip, C 18 Membrane 3 (3M Empore, USA) is filled in the lower end of the pipette tip 1, about 3mm in length, 1.2mg strong cation exchange resin filler (sulfonic acid group strong cation exchange resin filler) 2 (Applied Biosystems, USA) is filled in the pipette The lower end of the gun head 1 and C 18 膜3上。 Above the film 3.

[0060] Place the support block 4 on the upper end of the 1.5mL collection tube 5, place the proteome reactor on the collection tube 5 through the support block 4, and put the collection tube 5 into the centrifuge 6, and the protein solution or reagent can be made by centrifugation Flow through the proteomics reactor to complete the pre-concentration of proteins, enzymatic hydroly...

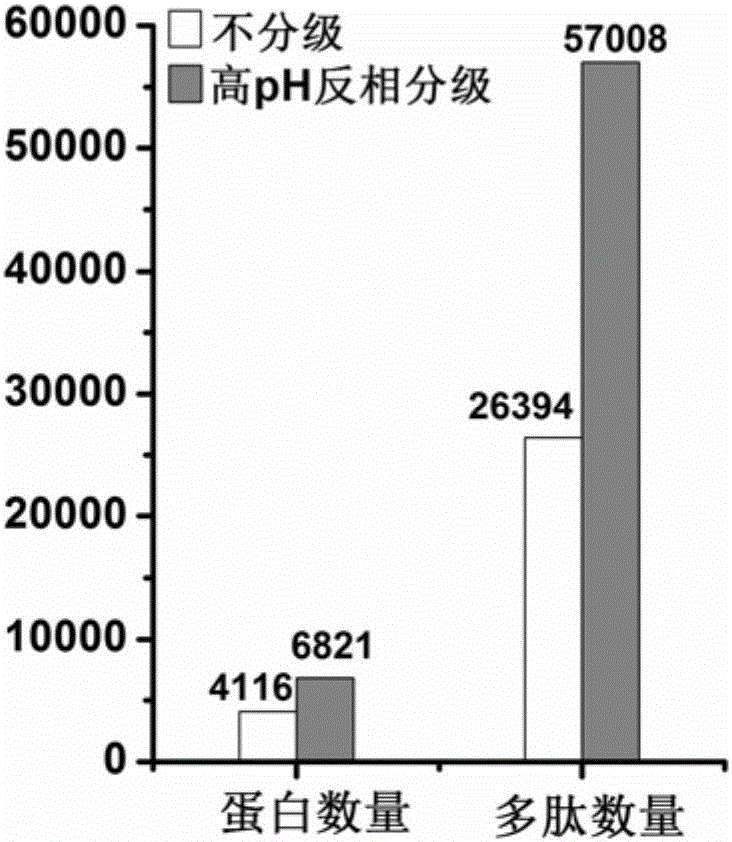

Embodiment 2

[0064] A proteomics reactor integrating protein pretreatment and high-pH reversed phase fractionation of peptides, including pipette tip 1, strong cation exchange resin filler 2 and C 18 膜3。 Film 3. Among them, pipette tip 1 is a standard 200μL tip, C 18 Membrane 3 (3M Empore, USA) is filled in the lower end of the pipette tip 1, about 3mm in length, 1.2mg strong cation exchange resin filler (sulfonic acid group strong cation exchange resin filler) 2 (Applied Biosystems, USA) is filled in the pipette gun Tip 1 and C 18 膜3上。 Above the film 3.

[0065] Place the support block 4 on the upper end of the 1.5mL collection tube 5, place the proteome reactor on the collection tube 5 through the support block 4, and put the collection tube 5 into the centrifuge 6, and the protein solution or reagent can be made by centrifugation Flow through the proteomics reactor to complete the pre-concentration of proteins, enzymatic hydrolysis, desalination of peptides, and high-pH reversed-phase frac...

Embodiment 3

[0069] A proteomics reactor integrating protein pretreatment and high-pH reversed phase fractionation of peptides, including pipette tip 1, strong cation exchange resin filler 2 and C 18 膜3。 Film 3. Among them, pipette tip 1 is a standard 200μL tip, C 18 Membrane 3 (3M Empore, USA) is filled in the lower end of the pipette tip 1, about 3mm in length, 1.2mg strong cation exchange resin filler (sulfonic acid group strong cation exchange resin filler) 2 (Applied Biosystems, USA) is filled in the pipette gun Tip 1 and C 18 膜3上。 Above the film 3.

[0070] Place the support block 4 on the upper end of the 1.5mL collection tube 5, place the proteome reactor on the collection tube 5 through the support block 4, and put the collection tube 5 into the centrifuge 6, and the protein solution or reagent can be made by centrifugation Flow through the proteomics reactor to complete the pre-concentration of proteins, enzymatic hydrolysis, desalination of peptides, and high-pH reversed-phase frac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com