Equivalent-magnetic-circuit full-powder-core high-frequency three-dimensional reactor

A reactor, powder core technology, applied in the direction of inductance with magnetic core, inductor, magnetic object, etc., can solve the three-phase reactor that cannot realize the full powder core magnetic core, the three-phase inductance is extremely unbalanced, the process Complex processing and other problems, to achieve the effect of volume reduction, high three-phase balance and uniform air gap

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

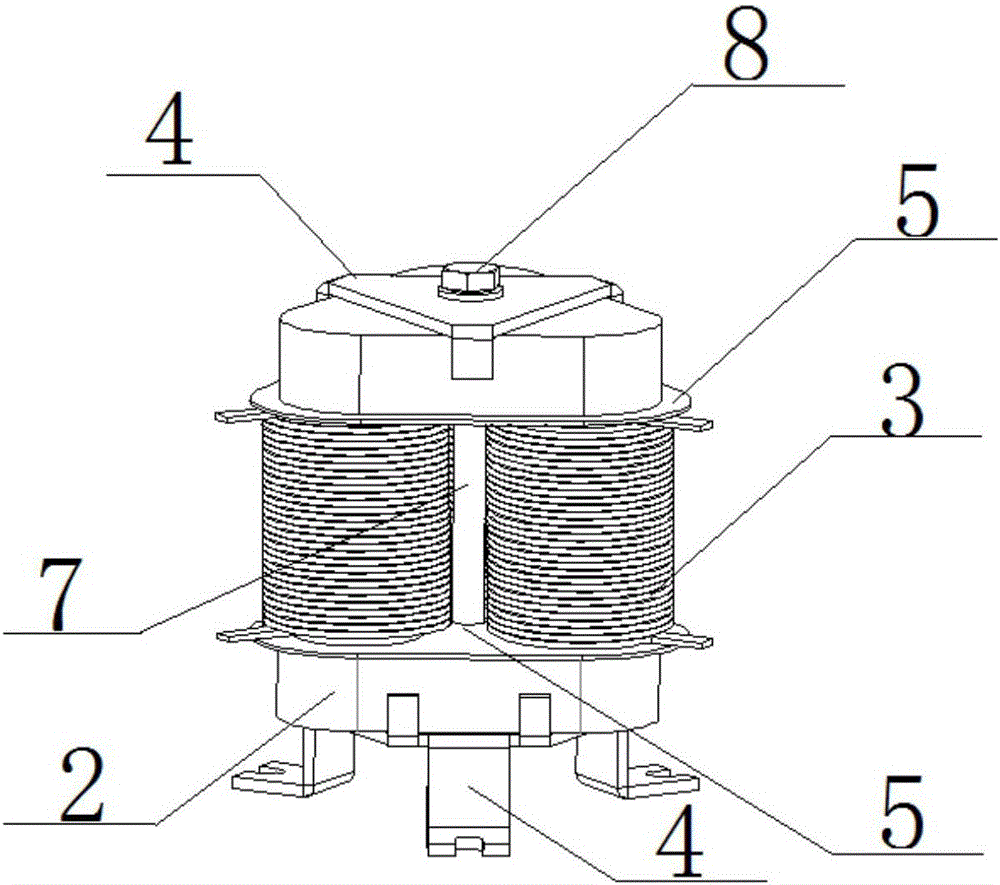

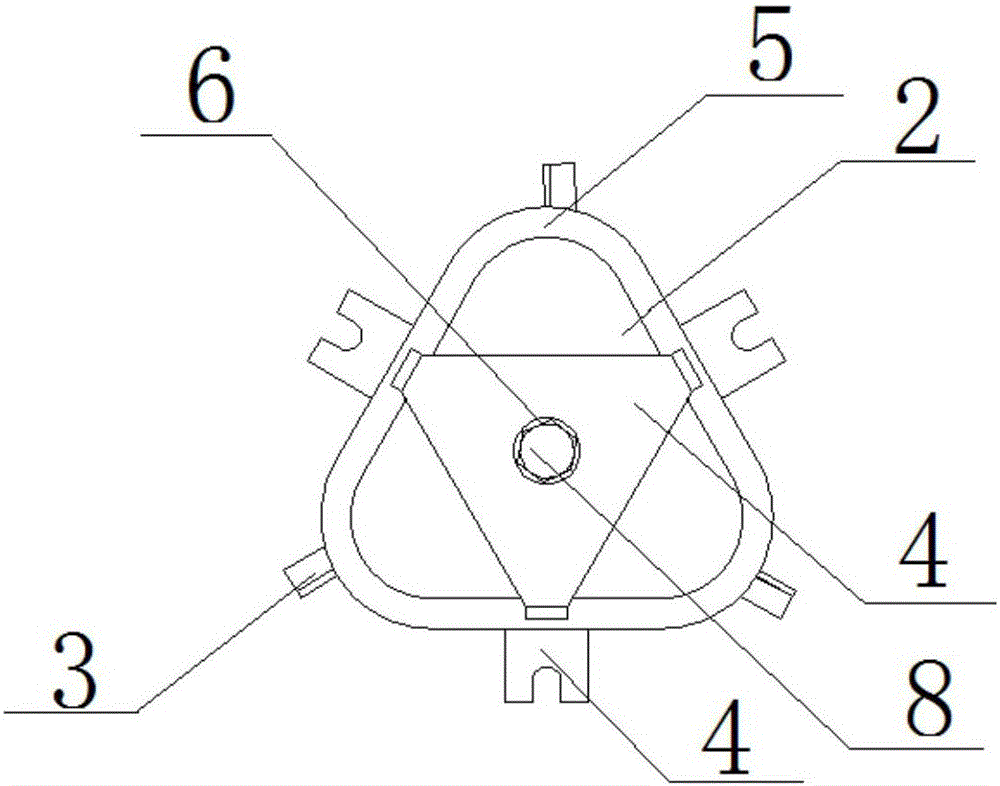

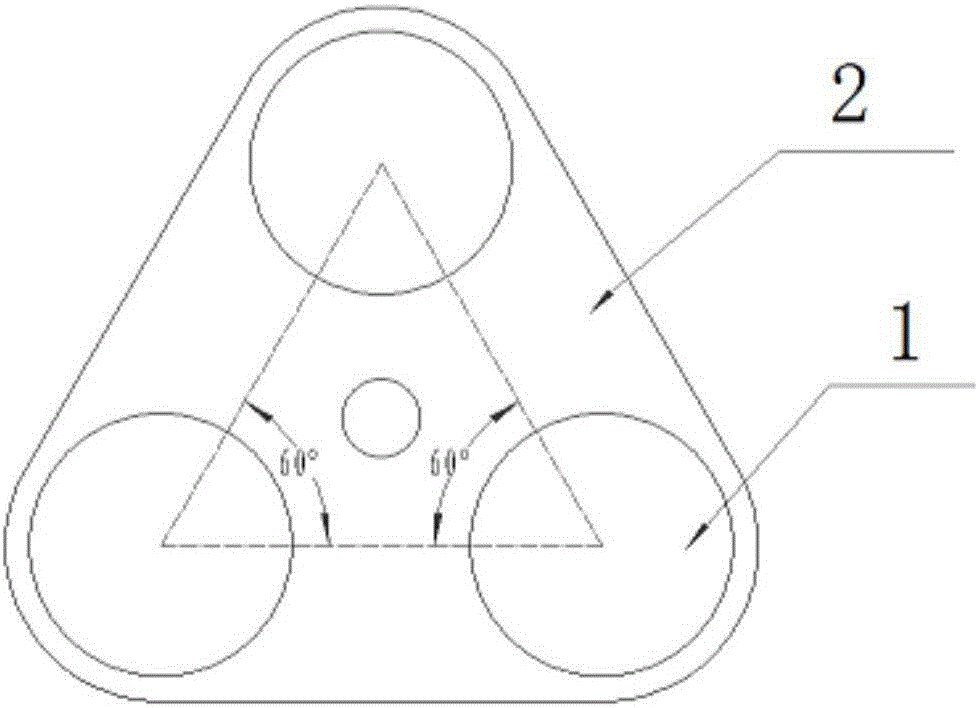

[0025] like Figure 1-3 As shown, the equal magnetic circuit full powder core high-frequency three-dimensional reactor described in the present invention is a kind of equal magnetic circuit full powder core high frequency three-dimensional reactor, including a magnetic core and a coil 3, and the magnetic core is composed of three identical cylinders The core column 1 arranged in an equilateral triangle, the magnetic cake 2 located on the upper and lower sides of the core column 1 composed of two same rounded triangles or circles, the core column 1 and the magnetic cake 2 are made of powder core materials, The coil 3 is wound around the three core posts 1 by using a flat wire. The magnetic circuit lengths of the three stems 1 are the same; the magnetic circuit includes the stem 1 and the magnetic cake 2; the powder core materials are iron powder, iron silicon powder, sendust powder, iron nickel powder, amorphous powder, nanocrystalline powder , the air gap of the powder core m...

Embodiment 2

[0027] One of the key points of the present invention is to completely solve the problem that a three-phase reactor cannot be designed due to three-phase unbalance of all-powder core materials. The existing technology adopts a planar structure. Phase B is located between phase A and phase C. Because the magnetic path length of phase A and phase C is longer than that of phase B, the three-phase inductance will be unbalanced. That is, one of the most important problems to be solved by the present invention is the imbalance between phases. Due to the technical prejudice in the prior art that the three phases can only be arranged on a plane, the technological development in this field has been stagnant. In the present invention, by designing a three-dimensional magnetic core, the top and bottom are magnetic cakes 2, and the middle is a shape arranged in an equilateral triangle. The reason why the above structure is adopted is based on the following considerations. To realize the...

Embodiment 3

[0029] The second key point of the present invention is: how to solve the heat dissipation problem of the high frequency reactor. In order to solve the above problems, those skilled in the art often consider cooling the reactor by improving the heat dissipation area from the perspective of heat dissipation. The invention further improves the heat dissipation problem of the powder core reactor. First of all, the angle of the three-dimensional structure is larger than that of the traditional planar structure. Assuming that the same loss occurs, the larger the space for heat dissipation, the faster the heat dissipation and the more obvious the effect. Secondly, the present invention considers that the loss comes from the coil 3 and the magnetic core. Therefore, this is why the present invention adopts flat wire as one of the shapes of the coil 3 . As we all know, compared with the traditional round wire, the flat wire has a larger heat dissipation area, and the skin effect is s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com