Method for one-step hydro-thermal synthesis of graphene-SnS2 composite counter electrode material

An electrode material, hydrothermal synthesis technology, applied in circuits, capacitors, photovoltaic power generation, etc., can solve the problem of low conductivity of two-dimensional sulfide, achieve high catalytic activity and stability, simple preparation method, and low price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

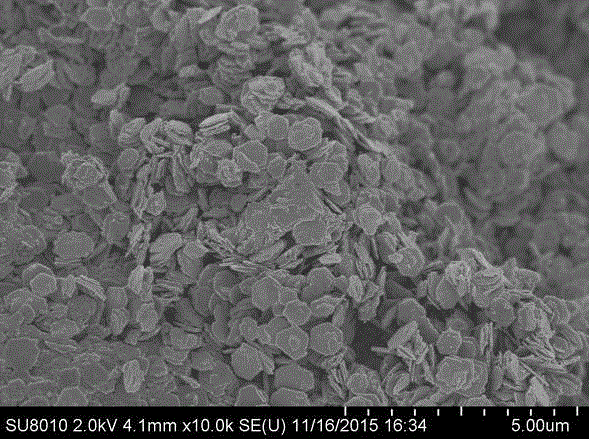

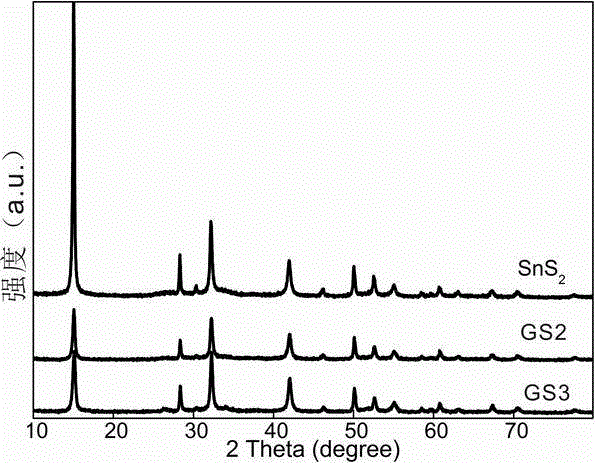

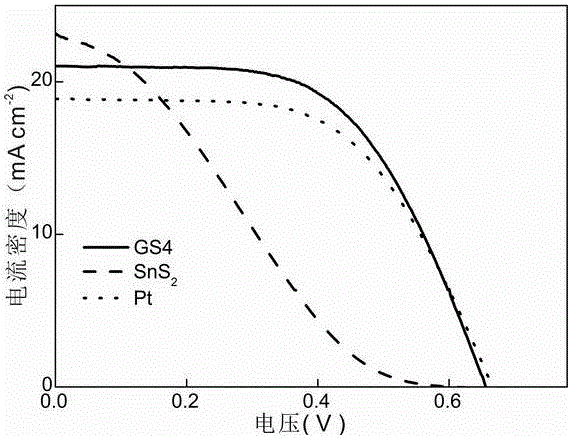

Embodiment 1

[0017] 5mmol of SnCl 4 ·5H 2 O and 10 mmol of thiourea were added to 80 mL of deionized water, stirred magnetically for 30 minutes, and the resulting homogeneous solution was transferred to a 100 mL reaction kettle, and subjected to hydrothermal reaction at 160° C. for 12 hours. After natural cooling, deionized water and and After fully washing with ethanol and vacuum drying at 60 °C for 24 hours, the hexagonal sheet-like SnS 2 Counter electrode material ( figure 1 , figure 2 ). The material is mixed with PVDF binder and ethanol to make a mixed slurry, which is scraped on the conductive glass to form a counter electrode, and assembled with a dye-sensitized photoanode and iodine electrolyte to form a dye-sensitized solar cell. The measured photovoltaic efficiency is 3.4 %( image 3 ).

Embodiment 2

[0019] 30 mg GO was ultrasonically dispersed into 80 mL deionized water to form a GO aqueous solution, and then 5 mmol of SnCl 4 ·5H 2 O and 20 mmol of thiourea were added to the above GO aqueous solution, magnetically stirred for 30 minutes to form a homogeneous solution, and the formed homogeneous solution was transferred to a 100mL reaction kettle, and hydrothermally reacted at 160°C for 24 hours. After natural cooling, deionized After fully washing with water and ethanol and vacuum drying at 60°C for 24 hours, the graphene-SnS 2 Composite counter electrode material (marked as GS2) ( figure 2 ). The composite counter electrode material is mixed with PVDF binder and ethanol to make a mixed slurry, which is scraped on conductive glass to form a counter electrode, and assembled with N719 dye-sensitized photoanode and iodine electrolyte to form a dye-sensitized solar cell. The efficiency is 7.2%.

Embodiment 3

[0021] 60 mg GO was ultrasonically dispersed into 80 mL deionized water to form a GO aqueous solution, and then 5 mmol of SnCl 4 ·5H 2 O and 20 mmol of thiourea were added to the above GO aqueous solution, magnetically stirred for 30 minutes to form a homogeneous solution, and the formed homogeneous solution was transferred to a 100mL reactor, and hydrothermally reacted at 120°C for 12 hours. After natural cooling, deionized After fully washing with water and ethanol and vacuum drying at 60°C for 24 hours, the graphene-SnS 2 Composite counter electrode material (marked as GS3) ( figure 2 ). The composite counter electrode material is mixed with PVDF binder and ethanol to make a mixed slurry, which is scraped on conductive glass to form a counter electrode, and assembled with N719 dye-sensitized photoanode and iodine electrolyte to form a dye-sensitized solar cell. The efficiency is 6.6%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com