Manufacturing method for flexible OLED and flexible OLED

A production method and flexible technology, applied in the field of flexible OLED, flexible OLED production, can solve the problems of increasing water vapor entering the device, shortening the life of the device, loose structure, etc., to achieve the effect of improving stability, improving reliability, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to further illustrate the technical means adopted by the present invention and its effects, the following describes in detail in conjunction with preferred embodiments of the present invention and accompanying drawings.

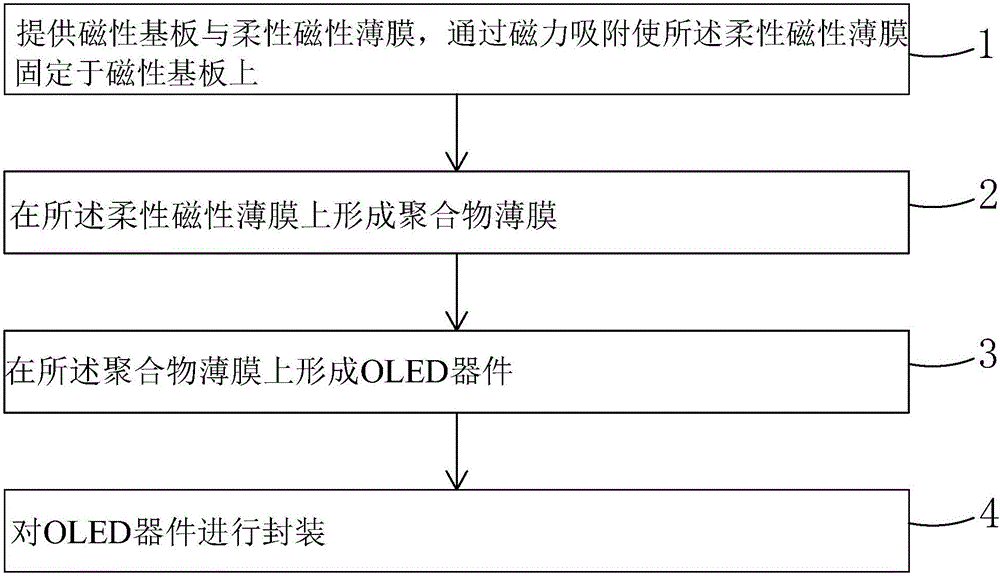

[0038] see figure 2 , the present invention firstly provides a kind of manufacturing method of flexible OLED, comprises the following steps:

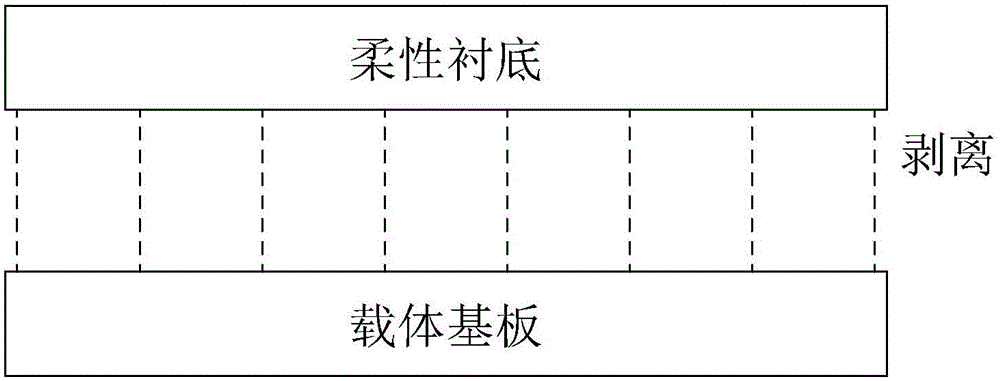

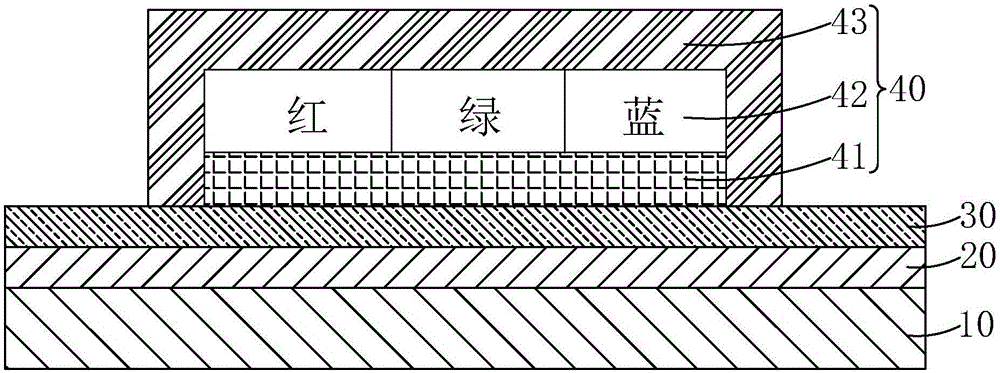

[0039] Step 1. Please refer to image 3 A magnetic substrate 10 and a flexible magnetic thin film 20 are provided, the magnetism of the magnetic substrate 10 is controllable, and the flexible magnetic thin film 20 is fixed on the magnetic substrate 10 by magnetic adsorption.

[0040] Preferably, the flexible magnetic film 20 is a metal film. When the thickness of the metal film is less than 100 μm, it exhibits good flexibility, and has good thermal stability and water vapor isolation ability, which can form an effective barrier for OLED devices. Protection, so that the performance of the OLED device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com