Surface-treated steel sheet, metal container covered with organic resin, and method for manufacturing surface-treated steel sheet

A technology for surface treatment of steel plates and organic resins, applied in surface reaction electrolytic coating, metal material coating process, superimposed layer plating, etc., can solve problems such as poor productivity, reduce fluorine concentration, reduce drainage load, excellent Effect of fluorine dissolution resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

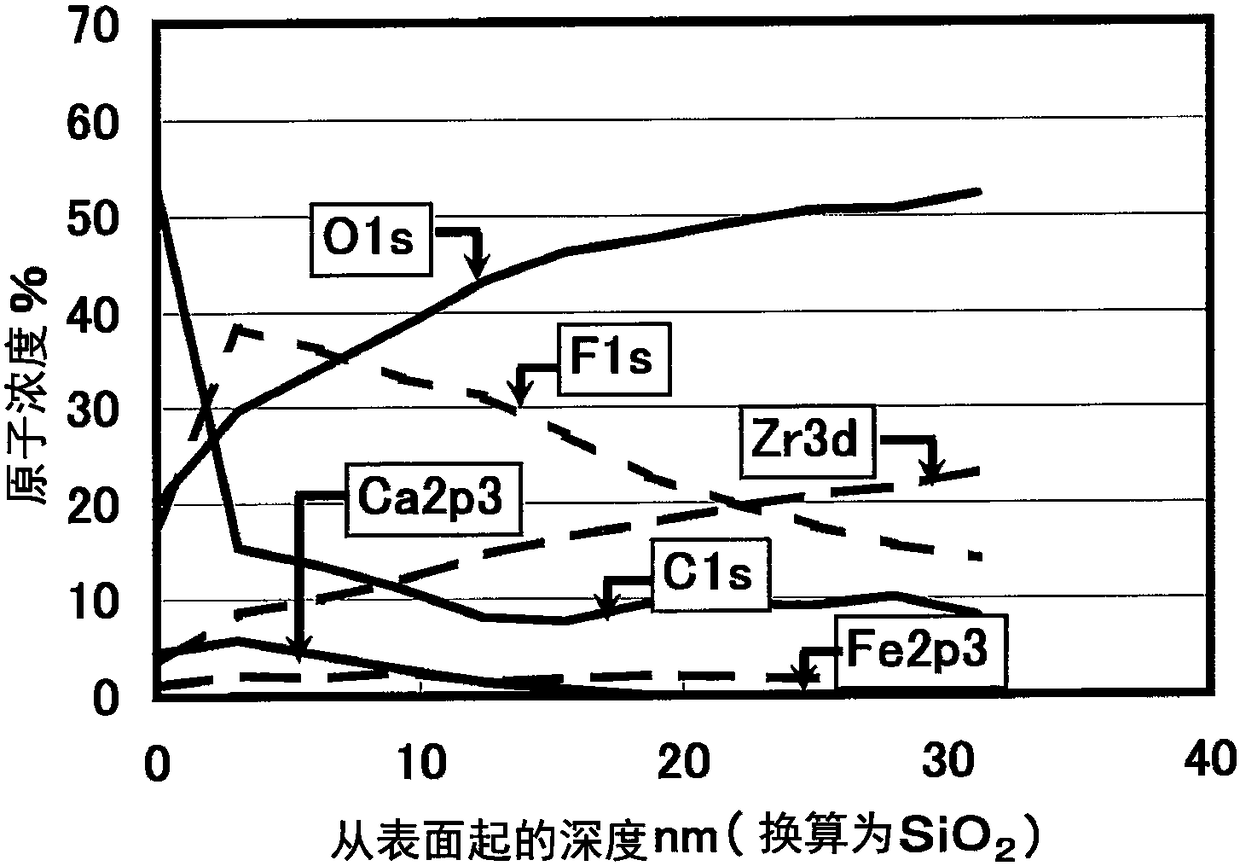

Embodiment 1

[0168] In the step of forming the film, first, a titanium plate covered with iridium is used as the relative electrolysis in the electrolytic treatment solution, and the steel plate is used as the cathode, at 3A / dm 2 The current density is energized once within 0.15 seconds, the steel plate is squeezed with a roller to remove the electrolytic treatment solution, washed with water at normal temperature, and further squeezed with a roller to remove the cleaning water. In the next step, the surface is conditioned by cathodic electrolytic treatment. As the aqueous solution for surface adjustment, an aqueous solution containing calcium lactate in an amount of 0.1 mol / l and having an electrical conductivity of 6.57 mS / cm and a pH of 6.96 was used. In an aqueous solution for surface conditioning maintained at a liquid temperature of 30°C, by repeating twice at 4A / dm 2 The step of conditioning the surface was carried out by cycling at a current density of 0.15 seconds followed by 0.1...

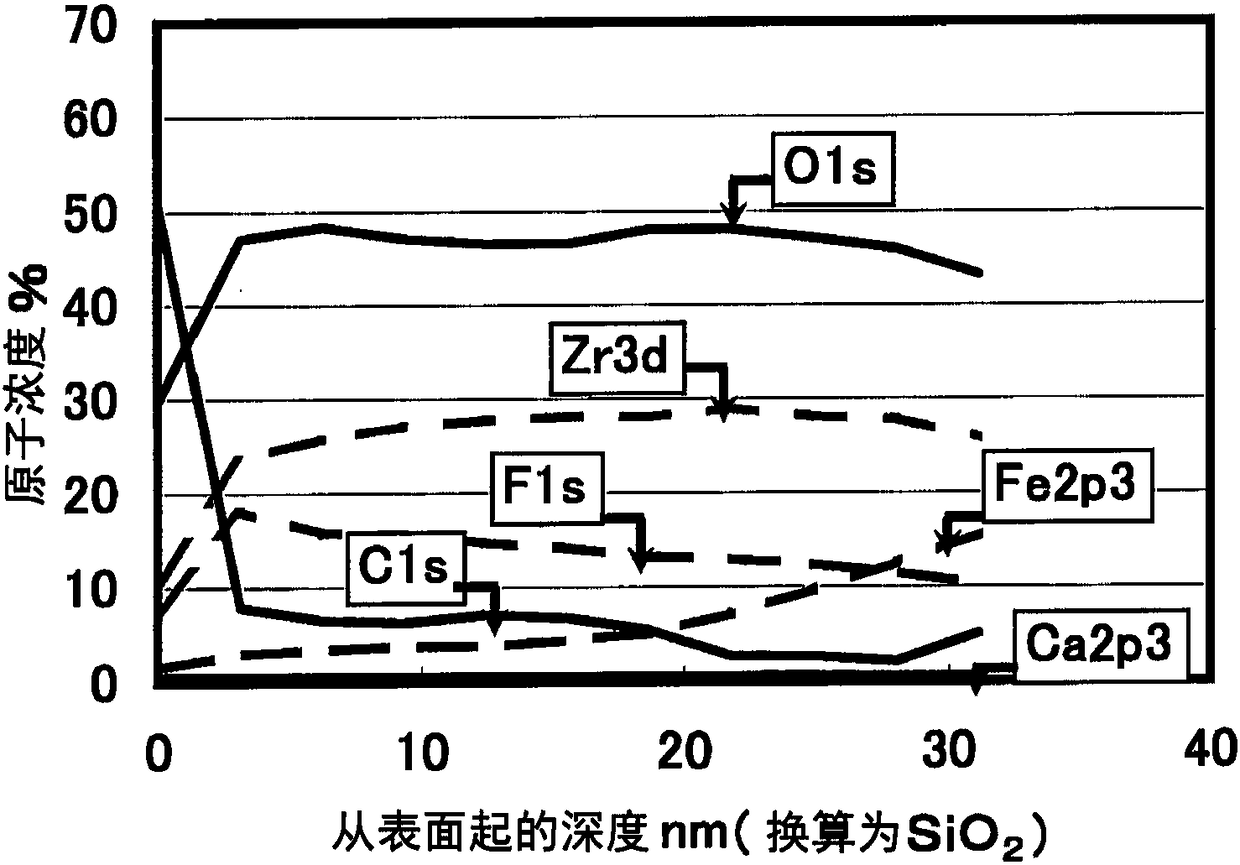

Embodiment 2

[0171] Except in the film forming step at 10A / dm 2 The current density was energized and the cycle was repeated twice, and in the step of conditioning the surface at 1A / dm 2 A surface-treated steel sheet was obtained in the same manner as in Example 1, except that electricity was applied at a current density of .

Embodiment 3

[0173] Except at 6.5A / dm in the step of conditioning the surface 2 A surface-treated steel sheet was obtained in the same manner as in Example 2, except that electricity was applied at a current density of .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com