Display or illumination device, and method for forming insulating film

A technology of lighting device and insulating film, which is applied in the direction of lighting device, photoengraving process of pattern surface, instruments, etc., to achieve the effect of suppressing light degradation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0408] [Preparation method of radiation-sensitive material]

[0409] The radiation-sensitive material can be prepared by mixing essential components such as a polymer (A), a photosensitizer (B), and a resin (C) and other optional components in a solvent (E), for example. Moreover, after mixing each component uniformly, you may filter the obtained mixture with a filter etc. in order to remove a foreign substance.

[0410] [Formation method of insulating film using radiation-sensitive material]

[0411] The method for forming the insulating film of the display or lighting device of the present invention comprises the following steps: step 1, using the radiation-sensitive material to form a coating film on the substrate; step 2, irradiating radiation to at least a part of the coating film; Step 3, developing the coating film irradiated with radiation; and Step 4, heating the developed coating film.

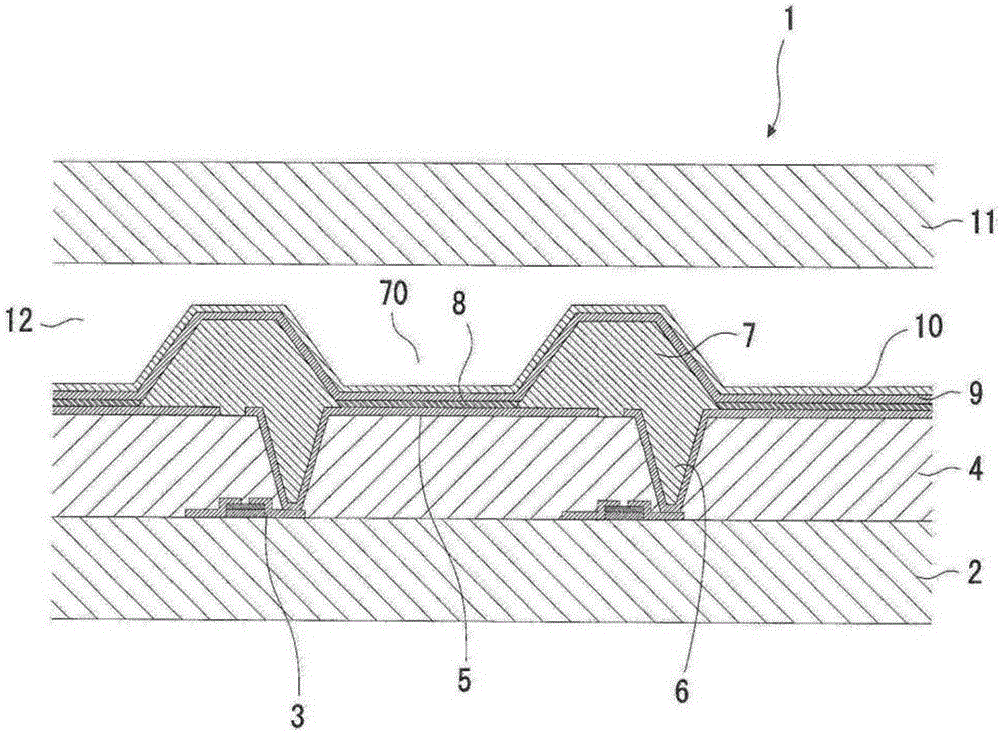

[0412] According to the method of forming the insulating film, an insulating f...

Embodiment

[0454] Hereinafter, although an Example demonstrates this invention more concretely, this invention is not limited to these Examples. In descriptions such as the following examples, "parts" are "parts by mass" unless otherwise mentioned.

[0455] [GPC Analysis]

[0456] The weight average molecular weight (Mw) and molecular weight distribution (Mw / Mn) of a polymer (A) and resin (C) were measured by the gel permeation chromatography (GPC) method under the following conditions.

[0457] ・Standard material: polystyrene conversion

[0458] ・Device: manufactured by Tosoh Co., Ltd., trade name: HLC-8020

[0459] ・Column: guard column (guard column) H manufactured by Tosoh Co., Ltd. XL -H, TSK gelG7000H XL 、TSK gel GMH XL 2 sticks, TSK gel G2000H XL connected in sequence

[0460] Solvent: Tetrahydrofuran

[0461] ・Sample concentration: 0.7% by mass

[0462] ·Injection volume: 70μL

[0463] ·Flow rate: 1mL / min

[0464] [NMR analysis]

[0465] The phenyl group content in p...

Synthetic example A1

[0467] [Synthesis Example A1] Synthesis of Polymer (A-1) (Polyimide)

[0468] After adding 390 g of γ-butyrolactone as a polymerization solvent to the three-necked flask, 120 g of 2,2′-bis(3-amino-4-hydroxyphenyl)hexafluoropropane as a diamine compound was added to the polymerization solvent. After dissolving the diamine compound in the polymerization solvent, 71 g of 4,4'-oxydiphthalic dianhydride was added as an acid dianhydride. Then, after reacting at 60 degreeC for 1 hour, 19 g of maleic anhydrides were added as a terminal blocking agent, and after reacting further at 60 degreeC for 1 hour, it heated up and reacted at 180 degreeC for 4 hours. About 600 g of the polyimide solution whose solid content concentration containing a polymer (A-1) was about 35 mass % was obtained. The Mw of the obtained polymer (A-1) was 8000.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| electrical resistivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com