Preparation method of regenerated silk fibroin membrane

A technology for regenerating silk and fibroin, which is applied in the polymer field, can solve the problems of many organic solvents, many operation steps, destruction of biological characteristics, etc., and achieves the effects of low production cost, simple and convenient operation process, and short production cycle.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Weigh 5.00 g of shredded Thai silk cocoon shells, put them into 2000 ml of 0.21 wt % sodium bicarbonate boiling aqueous solution for degumming treatment for 30 min. After repeated washing with deionized water for 2-3 times, move to a ventilated place to dry naturally to obtain degummed Thai silk.

[0029] Calcium chloride-formic acid solution with a concentration of 1.5wt% was prepared and 1.90g of the solution was weighed, placed in a 2ml centrifuge tube, and then 0.17g of degummed Thai silk was placed in the solution for dissolution, and the Thai silk was found within 2 minutes. Can be dissolved completely, just can get Thai silk protein solution.

[0030] Filtrate the Thai silk protein solution with a PTFE microporous filter membrane with a pore size of 0.45 μm, cast the filtrate on PDMS, and then place it in a 45°C oven to dry for 5 hours to prepare the Thai silk protein membrane.

Embodiment 2

[0032] Weigh 5.00 g of shredded Thai silk cocoon shells, put them into 2000 ml of 0.21 wt % sodium bicarbonate boiling aqueous solution for degumming for 30 min. After repeated washing with deionized water for 2-3 times, move to a ventilated place to dry naturally to obtain degummed Thai silk.

[0033]Prepare a calcium chloride-formic acid solution with a concentration of 2.0wt% and weigh 1.90g, put it in a 2ml centrifuge tube, and then put 0.17g of degummed Thai silk in the solution to dissolve it. It takes 1 minute to find the Thai silk. After being dissolved completely, Thai silk protein solution can be obtained.

[0034] Filtrate the Thai silk protein solution with a PTFE microporous filter membrane with a pore size of 0.45 μm, cast the filtrate on PDMS, and then place it in a 45°C oven to dry for 5 hours to prepare the Thai silk protein membrane.

Embodiment 3

[0036] Weigh 5.00 g of shredded Thai silk cocoon shells, put them into a boiling aqueous solution of sodium bicarbonate with a concentration of 0.21 wt%, and perform degumming for 30 min. After repeated washing with deionized water for 2-3 times, move to a ventilated place to dry naturally to obtain degummed Thai silk.

[0037] Prepare a calcium chloride-formic acid solution with a concentration of 6.0wt%, weigh 1.90g of the solution, place it in a 2ml centrifuge tube, and then dissolve 0.17g of degummed Thai silk in the solution, and find the Thai silk within 30s Just can be dissolved completely, just can obtain Thai silk protein solution.

[0038] Filtrate the Thai silk protein solution with a PTFE microporous filter membrane with a pore size of 0.45 μm, cast the filtrate on PDMS, and then place it in a 45°C oven to dry for 5 hours to prepare the Thai silk protein membrane.

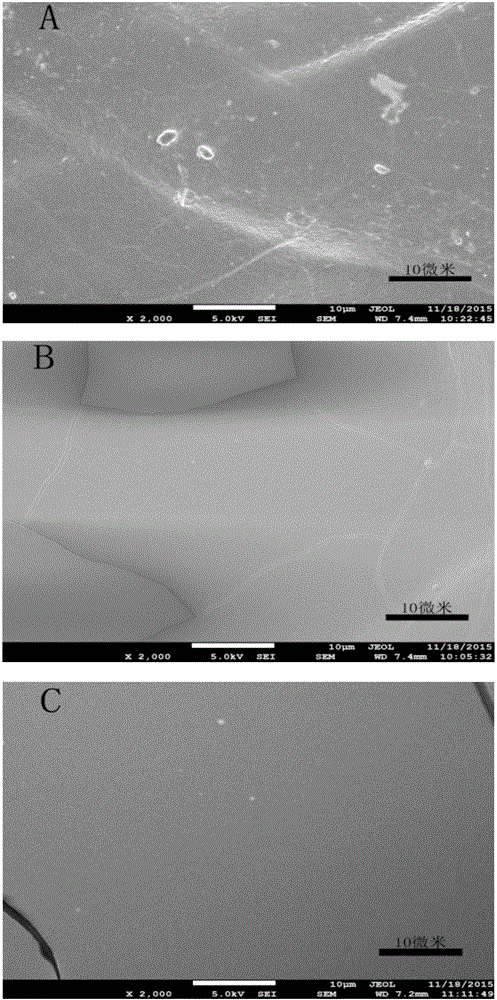

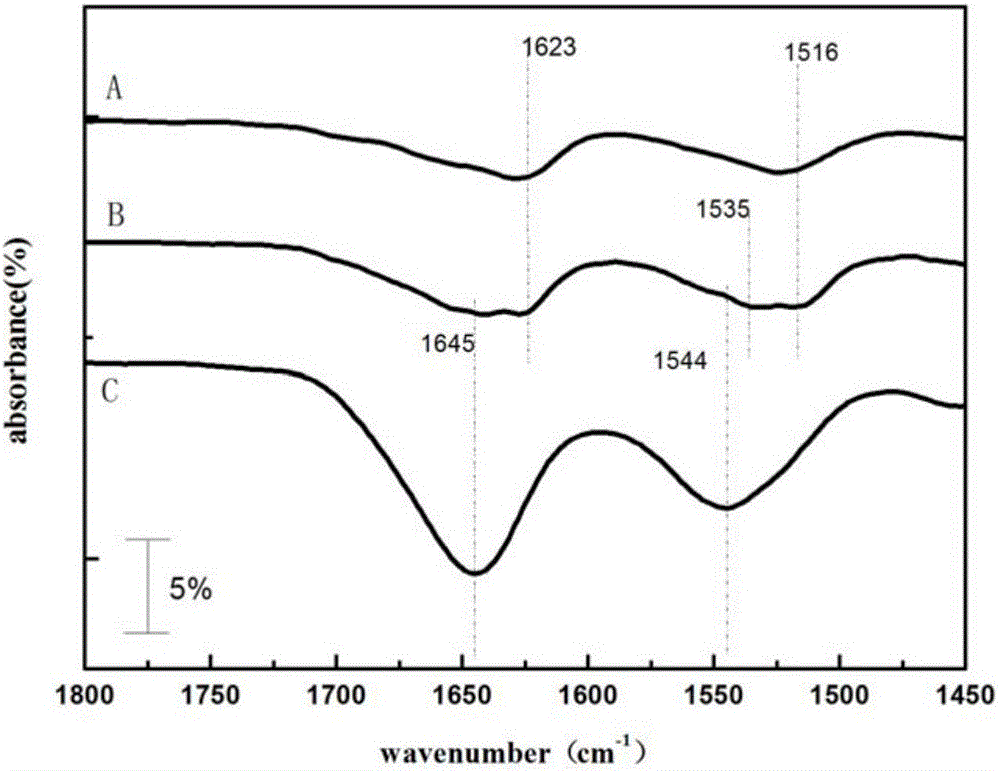

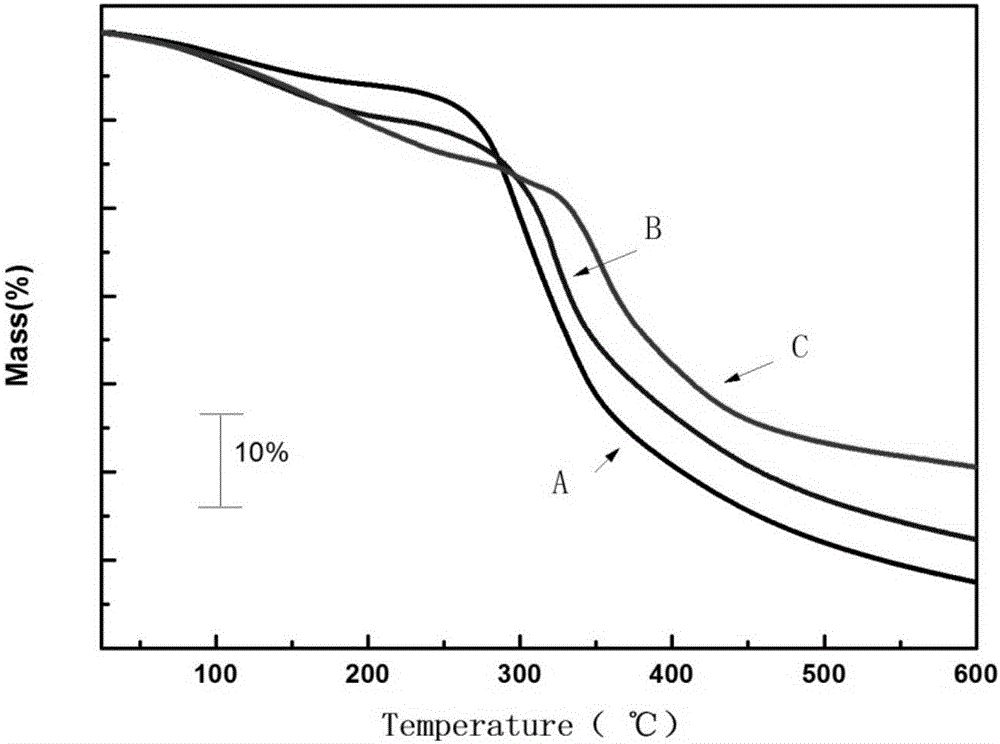

[0039] (1) Comparison of surface morphology and structure of silk protein membranes

[0040] figu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com