Method for saccharifying wood fiber raw material through mechanical activation in cooperation with alkali solid phase reinforcement

A technology of lignocellulosic raw materials and mechanical activation, which is applied in fermentation and other directions, can solve the problems of poor mechanical activation effect and high energy consumption, and achieve the effects of promoting deep development and utilization, small reaction volume, and reducing ineffective adsorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

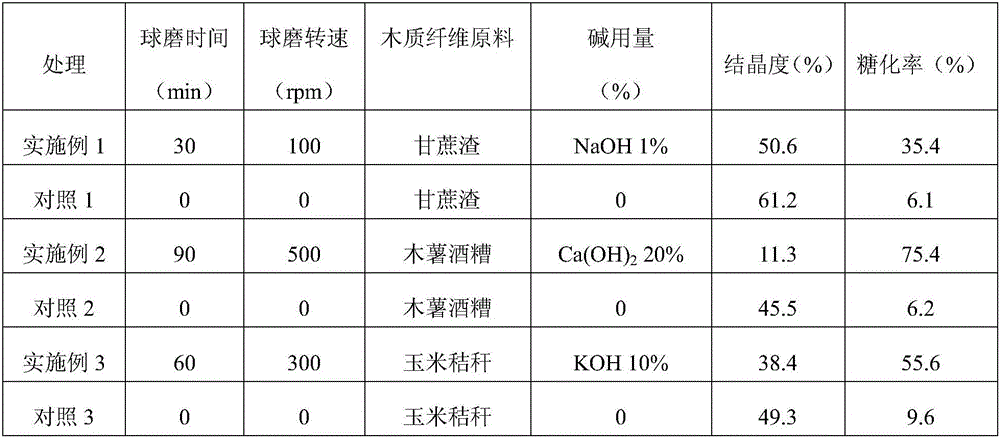

Embodiment 1

[0025] A method for saccharifying lignocellulosic raw materials with mechanical activation and alkali solid phase reinforcement, comprising the steps of:

[0026] (1) Raw material pre-treatment: first remove impurities in the lignocellulosic raw material, dry to a water content of 5%; pulverize to 40 meshes to obtain a processed lignocellulosic raw material; the lignocellulosic raw material is bagasse;

[0027] (2) Mechanical activation treatment: put the pretreated lignocellulosic raw material and alkali in a ball mill, at a constant temperature of 20°C, with a rotation speed of 100rpm, and after ball milling for 30min, the balls are separated to obtain activated lignocellulose powder; alkali The consumption accounts for 1% of lignocellulosic raw material weight; Described alkali is sodium hydroxide;

[0028] (3) Lignin elution: put the activated lignocellulose powder into a cleaner, wash off the lignin and excess alkali with water, and obtain the eluted lignocellulose raw ma...

Embodiment 2

[0031] A method for saccharifying lignocellulosic raw materials with mechanical activation and alkali solid phase reinforcement, comprising the steps of:

[0032] (1) Raw material pre-treatment: first remove impurities in the lignocellulosic raw material, dry to a water content of 30%; pulverize to 100 mesh to obtain a processed lignocellulosic raw material; the lignocellulosic raw material is cassava distiller's grains;

[0033] (2) Mechanical activation treatment: put the pretreated lignocellulosic raw material and alkali in a ball mill, at a constant temperature of 80°C, with a rotating speed of 500rpm, and after ball milling for 90min, the balls are separated to obtain activated lignocellulose powder; alkali The consumption accounts for 20% of lignocellulosic raw material weight; Described alkali is calcium hydroxide;

[0034] (3) Lignin elution: put the activated lignocellulose powder into a cleaner, neutralize calcium hydroxide with acid, and then elute with water to obt...

Embodiment 3

[0037] A method for saccharifying lignocellulosic raw materials with mechanical activation and alkali solid phase reinforcement, comprising the steps of:

[0038] (1) Raw material pretreatment: first remove impurities in the lignocellulosic raw material, dry to a water content of 20%; pulverize to 80 mesh to obtain a processed lignocellulosic raw material; the lignocellulosic raw material is corn stalk;

[0039] (2) Mechanical activation treatment: put the pretreated lignocellulosic raw material and alkali in a ball mill, at a constant temperature of 40°C, with a rotating speed of 300rpm, and after ball milling for 60min, the balls are separated to obtain activated lignocellulose powder; alkali The consumption accounts for 10% of lignocellulosic raw material weight; Described alkali is potassium hydroxide;

[0040] (3) Lignin elution: put the activated lignocellulose powder into a cleaner, wash off the lignin and excess alkali with water, and obtain the eluted lignocellulose raw...

PUM

| Property | Measurement | Unit |

|---|---|---|

| water content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com