Preparation method of continuous high-performance intermediate-phase asphalt-based carbon fiber

A technology of mesophase pitch and carbon fiber, applied in the field of pitch fiber, can solve the problems of complex process, low output, poor controllability, etc., and achieve the effects of good controllability, high yield and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

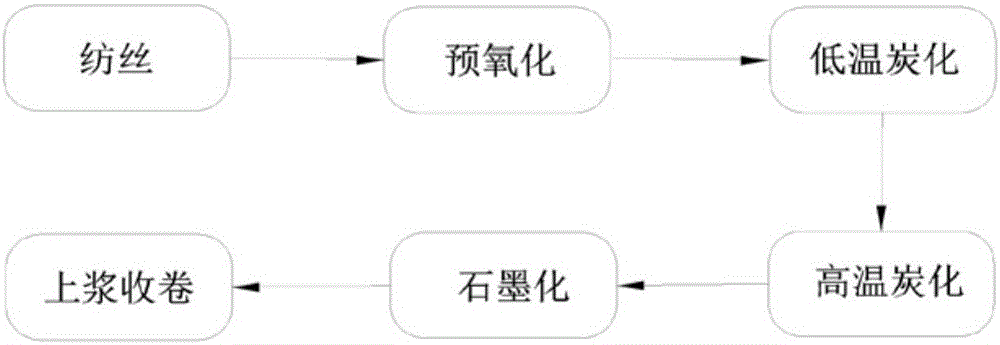

Method used

Image

Examples

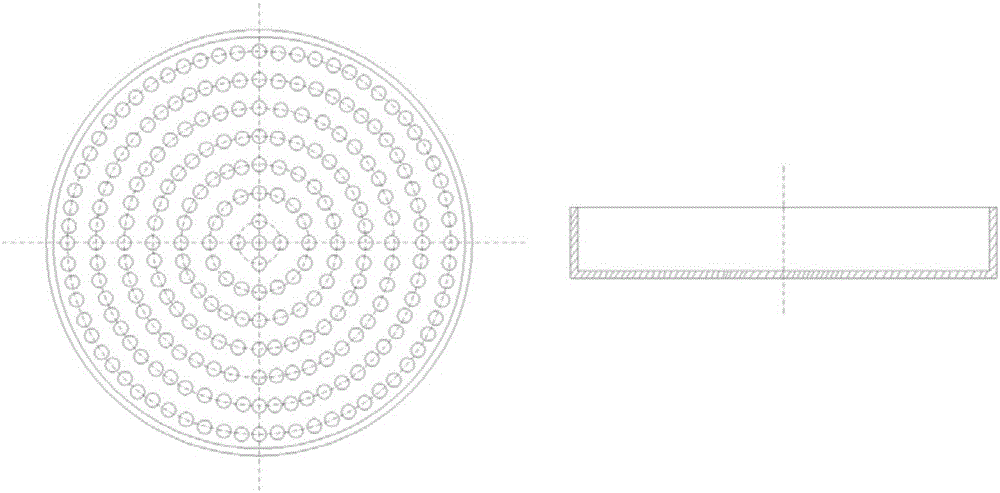

Embodiment 1

[0020] First, the spun continuous mesophase pitch-based carbon fiber precursors are regularly wound into a graphite crucible with micropores through a wire return mechanism; the graphite crucible with carbon fiber precursors is placed in a pre-oxidation furnace, and the While entering the air, the temperature in the pre-oxidation furnace is slowly raised to 280 °C at a rate of 1 °C / min, and the pre-oxidation is maintained at a constant temperature for 15 hours. The tar volatiles generated during the pre-oxidation process are discharged through the top of the furnace to be condensed and recycled; after the pre-oxidation is completed, the Vacuumize the pre-oxidation furnace, feed inert gas to keep the pre-oxidation furnace at normal pressure, continue to heat up the pre-oxidation furnace slowly at a rate of 1°C / min to 500°C, and keep constant temperature and low temperature for carbonization for 1h; continue to feed inert gas while pre-oxidation The furnace continues to heat up s...

Embodiment 2

[0022] First, the spun continuous mesophase pitch-based carbon fiber precursors are regularly wound into a graphite crucible with micropores through a wire return mechanism; the graphite crucible with carbon fiber precursors is placed in a pre-oxidation furnace, and the While entering the air, the temperature in the pre-oxidation furnace is slowly raised to 320 °C at a rate of 2 °C / min, and the pre-oxidation is maintained at a constant temperature for 6 hours. The tar volatiles generated during the pre-oxidation process are discharged through the top of the furnace to be condensed and recycled; after the pre-oxidation is completed, the Vacuumize the pre-oxidation furnace, feed inert gas to keep the pre-oxidation furnace at normal pressure, continue to heat up the pre-oxidation furnace slowly at a rate of 2°C / min to 500°C, and maintain a constant temperature and low temperature for carbonization for 1 hour; continue to feed inert gas while pre-oxidizing The furnace continues to ...

Embodiment 3

[0024] First, the spun continuous mesophase pitch-based carbon fiber precursors are regularly wound into a graphite crucible with micropores through a wire return mechanism; the graphite crucible with carbon fiber precursors is placed in a pre-oxidation furnace, and the While entering the air, the temperature in the pre-oxidation furnace is slowly raised to 300 °C at a rate of 2 °C / min, and the constant temperature pre-oxidation is maintained for 15 hours. The tar volatiles generated during the pre-oxidation process are discharged through the furnace top to be condensed and recycled; after the pre-oxidation is completed, the Vacuumize the pre-oxidation furnace, feed inert gas to keep the pre-oxidation furnace at normal pressure, continue to heat up the pre-oxidation furnace slowly at a rate of 5°C / min to 600°C, and keep constant temperature and low temperature for carbonization for 1 hour; continue to feed inert gas while pre-oxidation The furnace continues to heat up slowly at...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com