Novel high-back pressure cogeneration system

A cogeneration of heat and power, high back pressure technology, applied in heating systems, hot water central heating systems, household heating, etc. Unfavorable to energy saving and emission reduction, etc., to achieve the effect of providing flexible range, reducing heat loss, and saving energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

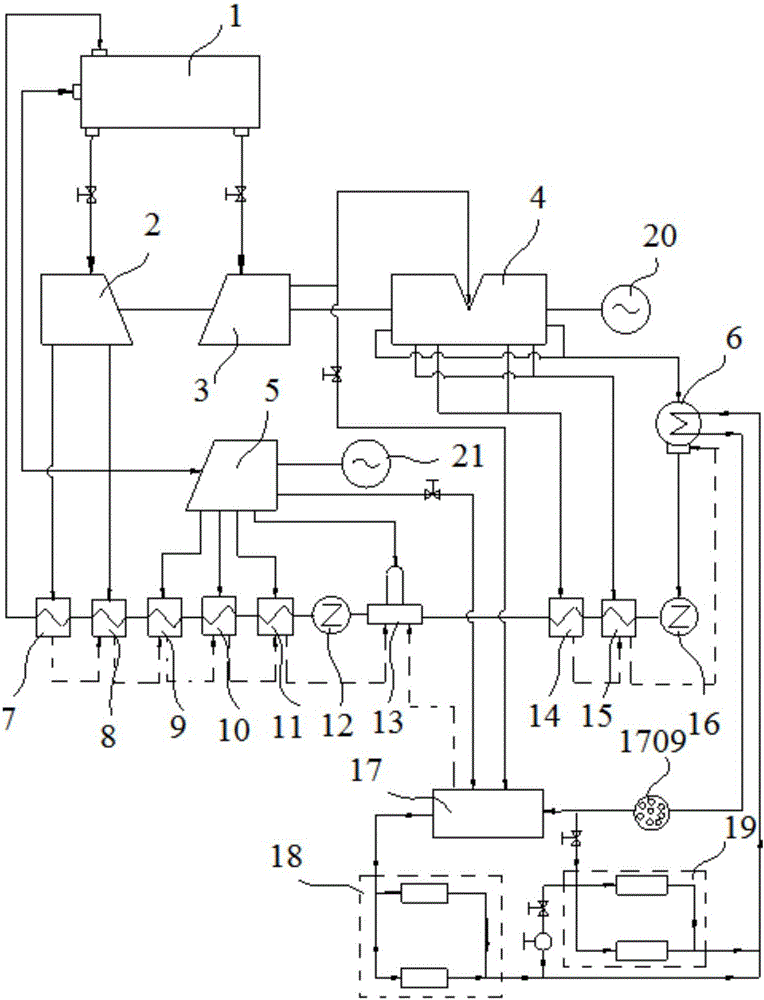

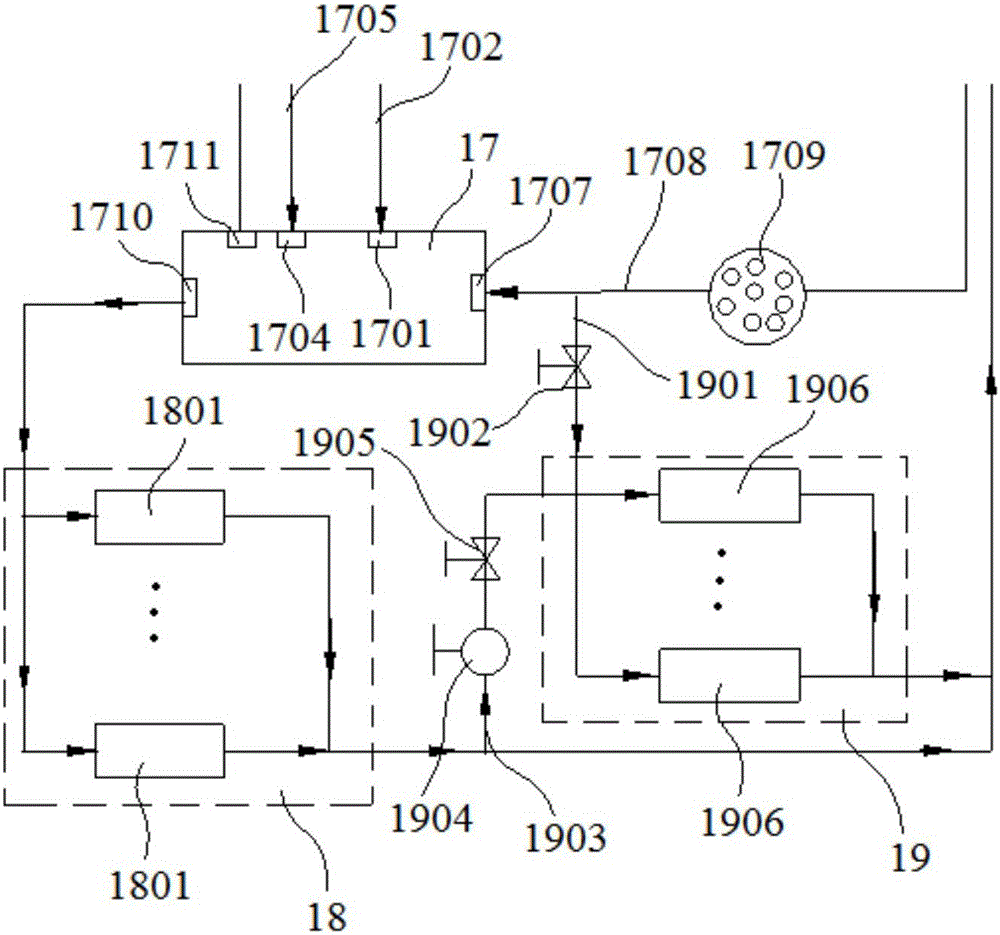

[0033] Such as figure 1 As shown, the novel high back pressure combined heat and power system of the present invention includes a power generation system and a heat supply system.

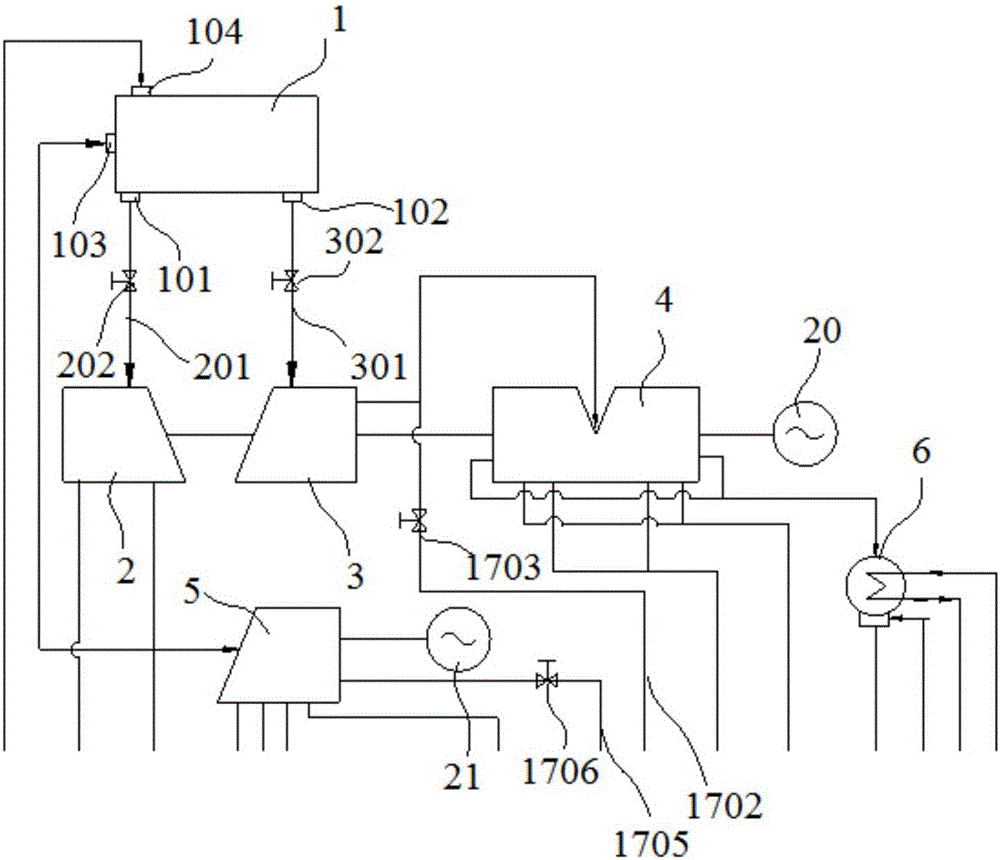

[0034] Such as figure 2 As shown, the power generation system includes a boiler 1, a high-pressure cylinder 2, a first medium-pressure cylinder 3, a low-pressure cylinder 4, a second medium-pressure cylinder 5, a condenser 6, a first high-pressure heater 7, and a second high-pressure heater 8. The first medium pressure heater 9, the second medium pressure heater 10, the third medium pressure heater 11, the first water pump 12, the deaerator 13, the first low pressure heater 14, the second low pressure heater 15, Second water pump 16. In this embodiment, the condenser 6 is a high back pressure heating condenser. The high-pressure cylinder 2, the first medium-pressure cylinder 3, and the low-pressure cylinder 4 are sequentially connected coaxially, the low-pressure cylinder 4 is connected with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com