An online large-range dynamic water level-temperature measurement system for geothermal wells

A geothermal water well and temperature measurement technology, applied in the direction of measurement, measurement devices, boreholes/well components, etc., can solve the problems of very strict requirements, fouling and clogging of measurement ports, unstable measurement data, etc., and eliminate zero point drift Error, convenient on-site installation, and simple manufacturing process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

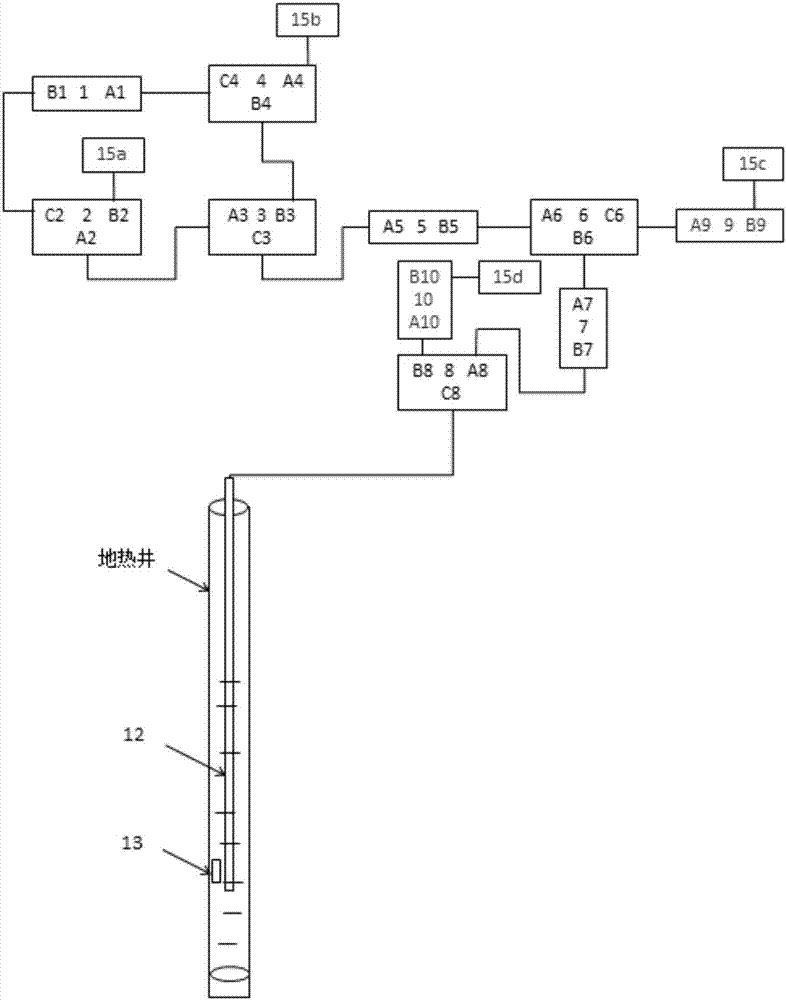

[0027] The composition and working process of the online large-scale dynamic water level-temperature measurement system for geothermal wells of the present invention will be described in detail below in conjunction with the accompanying drawings.

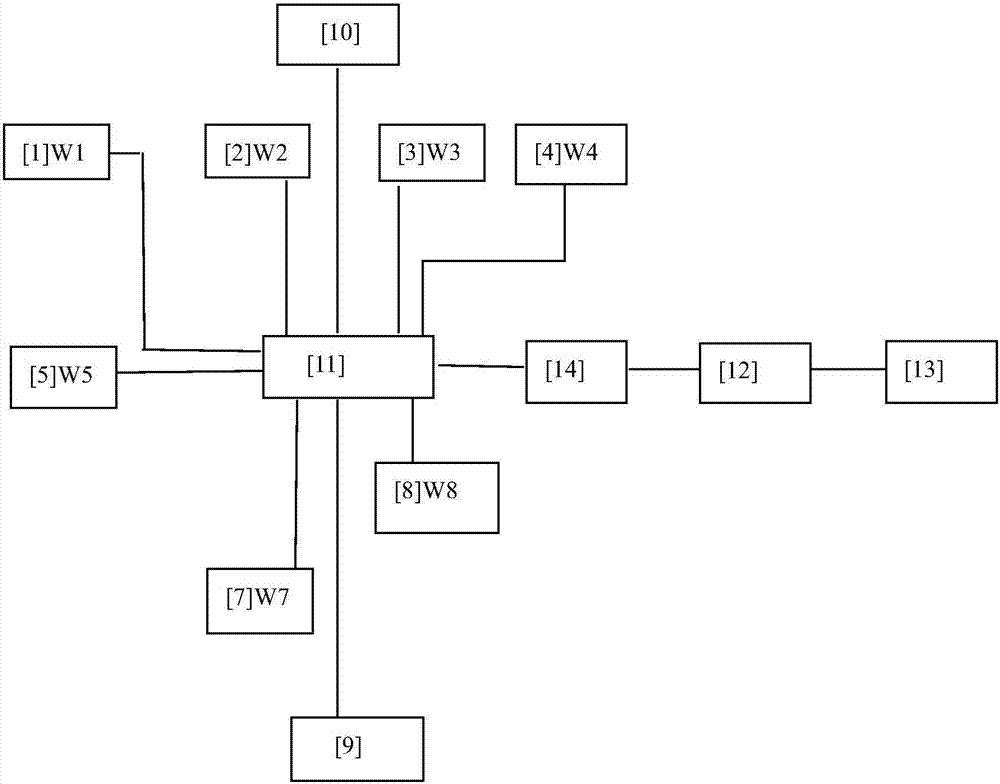

[0028] Such as figure 1 with figure 2 As shown, the geothermal well online large-scale dynamic water level-temperature measurement system of the present invention includes: crank connecting rod piston air pump 1, 1st-4th two-position three-way solenoid valves 2, 3, 4, 8, 1st-2nd One two-way solenoid valve 5, 7, gas storage tank 6, first-second differential pressure sensor transmitter 9, 10, controller with display screen 11, high temperature resistant air guide signal control cable 12, A temperature sensor 13, a temperature transmitter 14, and first to fourth one-way valves 15a-15d. The high temperature resistant gas conduction signal control cable 12 and the temperature sensor 13 are placed in the measuring pipe of the geotherm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com