A preparation process of copper-zinc-aluminum three-layer composite wire

A preparation process, copper-zinc-aluminum technology, applied in the manufacture of wire harnesses, extensible conductors/cables, etc., can solve the problems of reduced bonding strength of copper-clad aluminum wires, difficulty in automated production, inconvenient operation and maintenance, etc. The effect of increased density, large deformation and high temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A copper-zinc-aluminum three-layer composite wire with a diameter of 3 mm and a cladding wall thickness of 10% was prepared.

[0037] Specific steps are as follows:

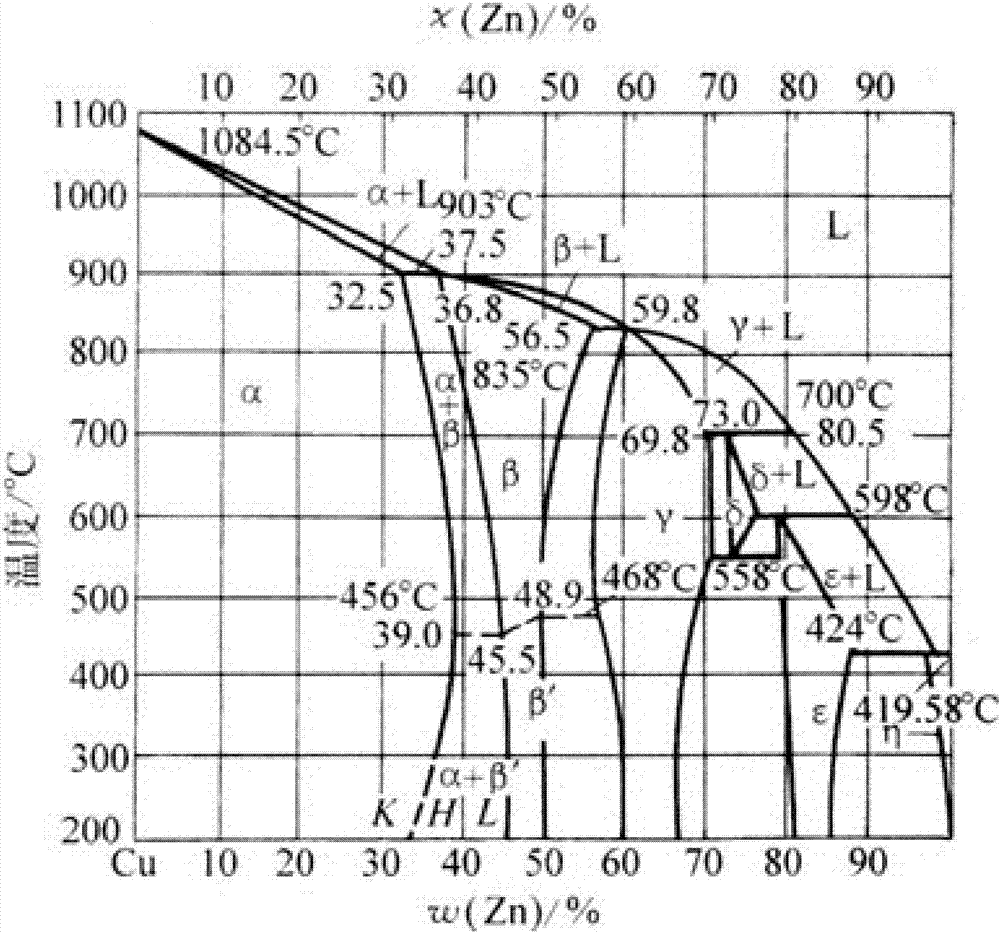

[0038]Step 1: Put the copper pipes that have been polished on the inner and outer surfaces into a tank filled with liquid zinc, and perform hot-dip galvanization on the inner and outer surfaces. The outer diameter of the copper pipe is 100mm, the wall thickness is 8mm, and the length of the copper pipe is 300mm. The galvanizing temperature is 480°C, and the thickness of the galvanizing layer is 15 μm;

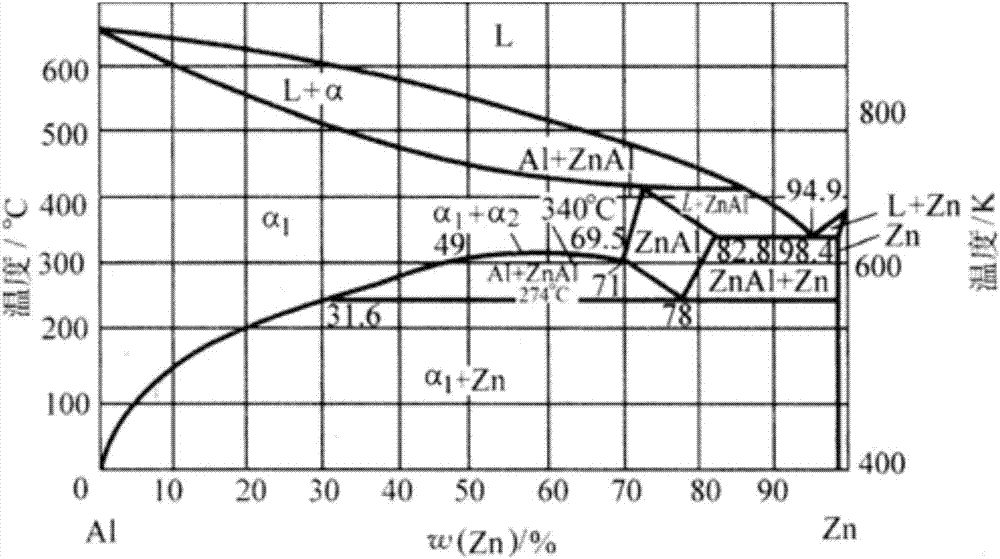

[0039] Step 2: Insert the first aluminum rod that has been polished on the outer surface into the hot-dip galvanized copper tube. The length of the first aluminum rod blank is the same as that of the copper tube, and the gap between the galvanized copper tube and the aluminum rod is between 0.8mm , Use a pipe drawing machine to draw the galvanized copper pipe and aluminum rod until they are bonded together...

Embodiment 2

[0044] A copper-zinc-aluminum three-layer composite wire with a diameter of 2 mm and a cladding wall thickness of 15% was prepared.

[0045] Concrete steps of the present invention are as follows:

[0046] Step 1: Put the copper tubes that have been polished on the inner and outer surfaces into a tank filled with liquid zinc, and then hot-dip galvanize the inner and outer surfaces. The outer diameter of the copper tube is 200mm, the wall thickness is 10mm, the length of the copper tube is 600mm, and the The galvanizing temperature is 500℃, and the thickness of the galvanizing layer is 30μm;

[0047] Step 2: Insert the first aluminum rod that has been polished on the outer surface into the hot-dip galvanized copper tube. The length of the first aluminum rod is the same as that of the copper tube. The gap between the galvanized copper tube and the first aluminum rod is 1.2mm During the period, the galvanized copper pipe and the first aluminum rod are drawn with a pipe drawing m...

Embodiment 3

[0052] A copper-zinc-aluminum three-layer composite wire with a diameter of 1 mm and a cladding wall thickness of 20% was prepared.

[0053] Concrete steps of the present invention are as follows:

[0054] Step 1: Put the copper pipes that have been polished on the inner and outer surfaces into a tank filled with liquid zinc, and perform hot-dip galvanization on the inner and outer surfaces. The outer diameter of the copper pipe is 250mm, the wall thickness is 15mm, the length of the copper pipe is 750mm, The galvanizing temperature is 520℃, and the thickness of the galvanizing layer is 30μm;

[0055] Step 2: insert the first aluminum rod that has been polished on the outer surface into the copper tube after hot-dip galvanizing, the length of the first aluminum rod is the same as that of the copper tube, and the gap between the galvanized copper tube and the first aluminum rod is at Between 1.5mm, the galvanized copper pipe and the first aluminum rod are drawn with a pipe dra...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com