Method for preparing two-dimensional material

A technology for two-dimensional materials and raw materials, applied in the field of preparation of two-dimensional materials, can solve the problems of difficulty in realizing high-speed large-scale mixers, smaller size of graphene nanosheets, and difficulty in large-scale production, etc. Implementability, to achieve automatable, highly adjustable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this example, 400 mL of ethylene glycol aqueous solution is firstly prepared in a beaker, wherein the volume ratio of ethylene glycol to water is 4:1. Then, add the weighed molybdenum disulfide into the configured ethylene glycol aqueous solution, and use a magnetic stirrer for initial dispersion, wherein the mass concentration of molybdenum disulfide is 3 mg·ml -1 .

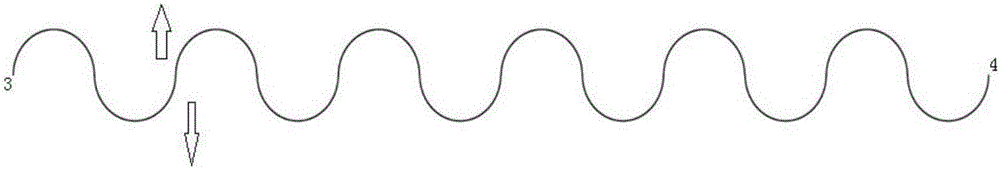

[0048] This embodiment selects the reactor using the S-shaped channel, wherein the width of the S-channel is 1mm, the diameter of the semicircle of the S-channel is 2cm, the depth of the S-channel is 1.5cm, and 12 semi-circles of the S-channel are connected in sequence horizontally composition, wherein the opening directions of two adjacent semicircles are opposite; the Dean value corresponding to the S-shaped channel reactor is 83.

[0049] In this embodiment, a power system consisting of an air compressor and a diaphragm pump is selected, wherein the operating pressure of the air compressor is 0.6Mp...

Embodiment 2

[0054] In this embodiment, 300 mL of sodium cholate aqueous solution is first configured in a beaker, and its concentration is 0.6 mg·ml -1 ; Then, after adding the weighed molybdenum disulfide, add the configured sodium cholate aqueous solution, and use a magnetic stirrer to carry out initial dispersion, wherein the mass concentration of molybdenum disulfide is 7mg·ml -1 .

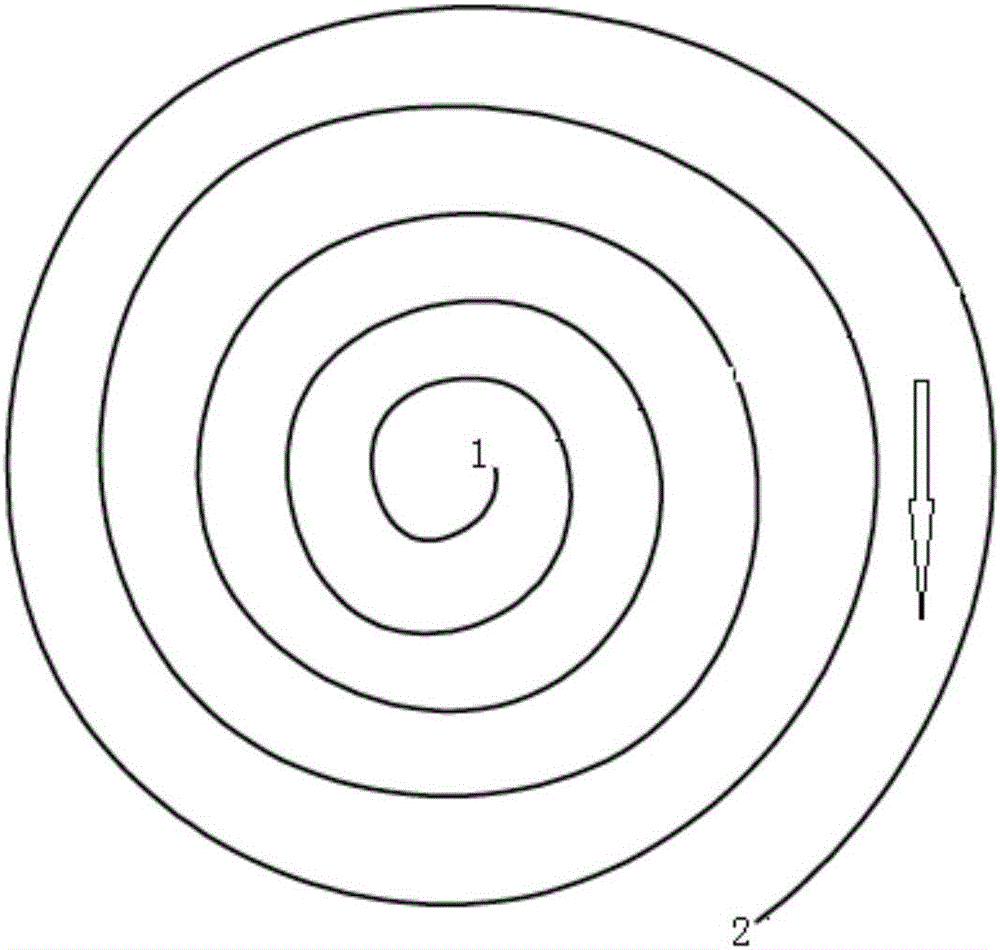

[0055] This embodiment selects the reactor that uses concentric circular flow channel, wherein, the width of concentric circular flow channel is 2mm, and the maximum circle diameter of concentric circular flow channel is 20cm, and the depth of concentric circular flow channel is 1.5cm, and concentric circular flow channel consists of Composed of 10 concentric circles; and the Dean number corresponding to the concentric circle flow channel reactor is 70.

[0056] In this embodiment, a power system consisting of an air cylinder and a diaphragm pump is selected. The operating pressure of the air cylinder is...

Embodiment 3

[0062] In this example, N-methylpyrrolidone is used as the dispersion liquid. First, weigh 400mL of N-methylpyrrolidone and place it in a beaker. Then, add the weighed graphene into the above-mentioned N-methylpyrrolidone solution, and use magnetic Stirrer for initial dispersion, wherein the mass concentration of graphene is 5mg·ml -1 .

[0063]Since the exfoliated graphene in this embodiment is difficult to dissolve in the solvent at the initial stage, this embodiment selects the combination of concentric circular flow channel reactor and S-shaped flow channel reactor, that is, the concentric circular flow channel with less flow resistance is used first. Reactor, and then use the S-shaped channel reactor with larger flow resistance.

[0064] According to the selected reactor to use the corresponding power system, the concentric circular channel reactor should choose to use the power system composed of air cylinder and diaphragm pump; the S-type flow channel reactor should ch...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com