Design and calculation method for inner conductor of quasi-microstrip ferrite circulator

A design calculation and ferrite technology, which is applied to waveguide devices, electrical components, circuits, etc., and can solve the problems of difficult design and debugging, complex structure of ferrite circulators, and poor temperature performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

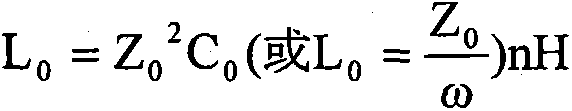

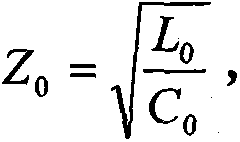

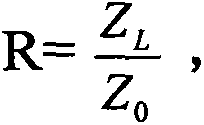

[0007] 1. Parallel inductance L composed of triangular inner conductors 0 and capacitance C 0 Calculation of : In the ideal case of ignoring the electromagnetic loss, L 0 C 0 When a parallel circuit resonates, it is a low impedance circuit, and its characteristic impedance value According to the document "Jiang Renpei, Xu Jidong "Thin Type Strip Line Circulator with internal matching LC-networks" 10th international Conference on microwave Ferrites PP344-348september 1990", the impedance value is between 10 and 20 ohms. When angular frequency ω = 1 L 0 C 0 , get:

[0008] C 0 = 1 ω Z 0 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com