A method for removing the toxicity of ginkgo fruit based on a combination of physical and enzymatic methods

A ginkgo, enzymatic technology, applied in the directions of drug combination, sexual diseases, food science, etc., can solve the problems of loss of active and nutrient components, decline of ginkgo efficacy, environmental pollution, etc., and achieve high social and economic benefits and low processing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

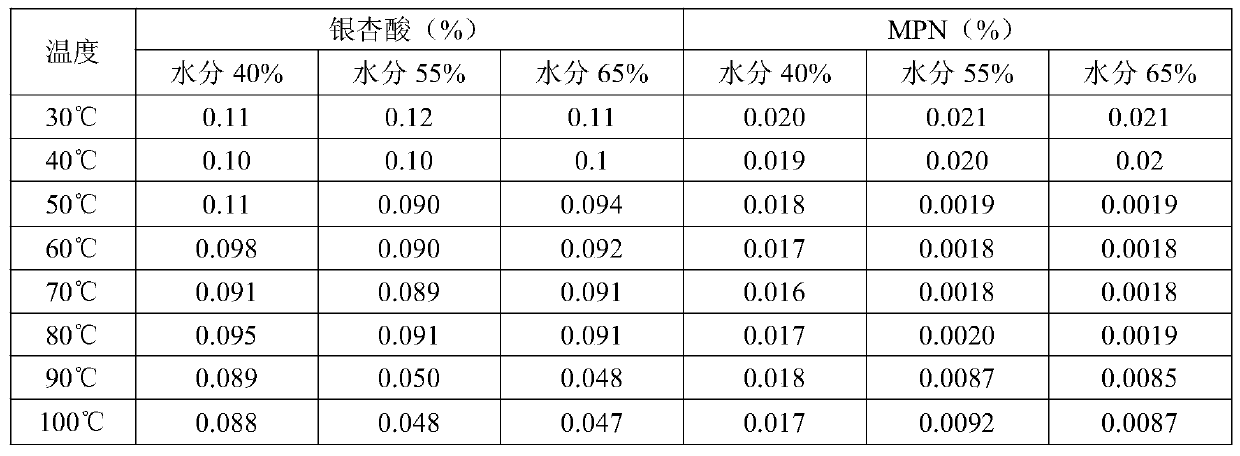

[0044] Embodiment 1 A kind of ginkgo toxicity compound processing detoxification method

[0045] (1) Take the ginkgo fruit freshly removed from the outer testa, and keep the water content of the ginkgo fruit higher than 60% in an environment with a temperature of 60° C. for 5 hours.

[0046] (2) Heat the ginkgo fruit to 100°C for 2 hours, and use a temperature-controlled drying oven for the heating method of the modified step. During the heating process, do not turn on the blast and seal it to maintain a certain humidity;

[0047] (3) Ginkgo fruit treated in the previous step is dried at a temperature of 90°C using temperature-controlled blast drying equipment, so that the water content of the ginkgo fruit is reduced to 30%, and the ginkgo fruit is manually dehulled, removed from the inner testa and germ;

[0048] (3) Ginkgo after removing the germ, further utilize the method and temperature described in (2) to dry, make moisture reach 10%.

[0049] Relevant composition detec...

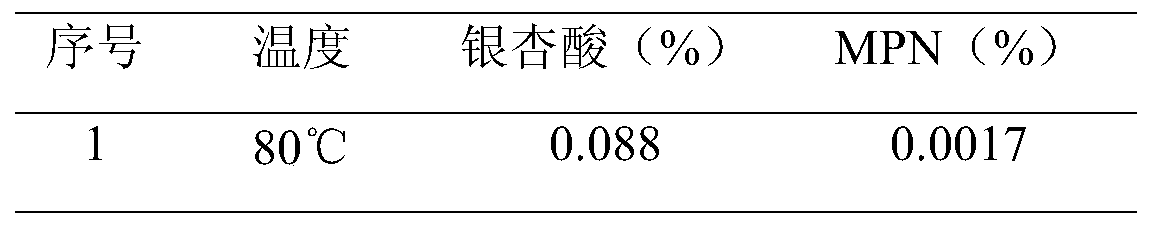

Embodiment 2

[0050] Embodiment 2 A kind of ginkgo toxicity compound processing detoxification method

[0051] (1) Take the ginkgo fruit after removing the outer testa and drying it in the sun, and keep the water content of the ginkgo fruit higher than 50% in an environment with a temperature of 50° C. for 4 hours.

[0052] (2) Heat the ginkgo fruit to 90°C for 6 hours. The heating method of this step adopts infrared temperature-controlled drying equipment, and the heating process is moderately humidified and airtight to maintain a certain humidity;

[0053] (3) The ginkgo fruit treated in the previous step is dried and roughly dried at a temperature of 100°C using temperature-controlled microwave drying equipment, so that the water content of the ginkgo fruit is reduced to 35%, and the ginkgo fruit is shelled and seeded by a combination of manual and mechanical methods skin and germ;

[0054] (4) The ginkgo fruit after germination is directly used for the development of related ginkgo pr...

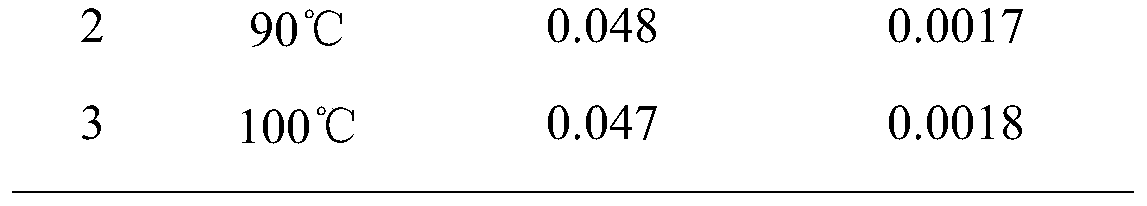

Embodiment 3

[0056] Embodiment 3 A kind of ginkgo toxicity compound processing detoxification method

[0057] (1) Take the ginkgo fruit, and keep the water content of the ginkgo fruit higher than 60% in an environment with a temperature of 70° C. for 2 hours.

[0058] (2) Heat the ginkgo fruit to 100°C for 2 hours. The heating method of this step adopts microwave temperature-controlled drying equipment, and the heating process is moderately humidified and airtight to maintain a certain humidity;

[0059] (3) Ginkgo fruit processed in the previous step is dried and roughly dried at a temperature of 100° C. using temperature-controlled microwave drying equipment, so that the water content of the ginkgo fruit is reduced to 35%. The ginkgo fruit is shelled by mechanical pressing, and the germ is removed by mechanical shock;

[0060] (4) The ginkgo fruit after removing the germ is further dried by infrared drying equipment to make the moisture reach 20%, reaching the humidity required for furt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com