Flavored meat product and preparation method thereof

A technology of meat products and flavor, applied in the field of flavor meat products and its preparation, can solve the problems of single flavor and unbalanced nutrition, and achieve the effects of unique flavor, promotion of degradation, and enhancement of flavor

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

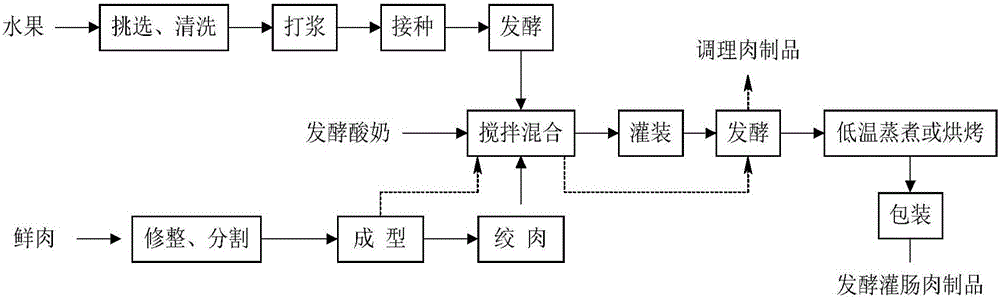

Method used

Image

Examples

Embodiment 1

[0037] A formula for flavored meat products, the formula consists of the following raw materials in parts by weight:

[0038] Yak meat 70g, fermented pulp 10g, fermented yogurt 10g, starch 2g, protein powder 1g, salt 1.5g, sugar 2g, spices 1g.

[0039] A processing method for flavored meat products, comprising the following steps:

[0040] (1) Preparation of fermented fruit pulp. Pineapple is selected, cleaned, and inedible parts removed. After beating, 80 parts of fruit pulp are added with 10 parts of sugar, and 2 parts of yeast are inoculated. After mixing, ferment in the dark. Fermentation temperature is 32 ° C, fermentation time 30 days;

[0041] (2) Fresh milk for the preparation of fermented yoghurt is degreased and milk fat standardized, and processed to produce yoghurt. The ratio of bacteria used is Bacillus bulgaricus: Streptococcus lactis = 1:1, the fermentation time is 220min, and the sugar content does not exceed 7%. After testing, the acidity is 100°T, the taste...

Embodiment 2

[0049] A formula for flavored meat products, the formula consists of the following raw materials in parts by weight:

[0050] Pork 90g, fermented pulp 20g, fermented yogurt 10g, starch 2g, protein powder 4g, salt 2g, sugar 3g, spices 2g.

[0051] A processing method for flavored meat products, comprising the following steps:

[0052] (1) Preparation of fermented fruit pulp. Lemons are selected, cleaned, and inedible parts removed. After beating, 80 parts of fruit pulp are added with 10 parts of sugar, and 2 parts of yeast are inoculated. After mixing, ferment in the dark. 30 days;

[0053] (2) Fresh milk for the preparation of fermented yoghurt is degreased and milk fat standardized, and processed to produce yoghurt. The ratio of bacteria used is Bacillus bulgaricus: Streptococcus lactis = 1:1, the fermentation time is 220min, and the sugar content does not exceed 7%. After testing, the acidity is 100°T, the taste is sweet and moist, and the milk taste is fragrant and delici...

Embodiment 3

[0058] A formula for flavored meat products, the formula consists of the following raw materials in parts by weight:

[0059] Chicken 90g, fermented pulp 30g, fermented yogurt 5g, starch 6g, protein powder 1g, sugar 6g, salt 1g, spices 0.8g.

[0060] A processing method for flavored meat products, comprising the following steps:

[0061] (1) Preparation of fermented fruit pulp Papaya and apple are selected, cleaned, and inedible parts removed, mixed and beaten in 1:1 parts by weight, and then 10 parts of white sugar is added to every 80 parts of fruit pulp, 1 part by weight of yeast is inoculated, and after mixing Dark fermentation, fermentation temperature 37 ℃, fermentation time 20 days;

[0062] (2) The fresh milk used for the preparation of fermented yogurt is degreased and milk fat standardized, and processed to produce yogurt. The ratio of Bacillus bulgaricus to the total number of Streptococcus lactis colonies used is 1:1, the fermentation time is 200min, the sugar con...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com