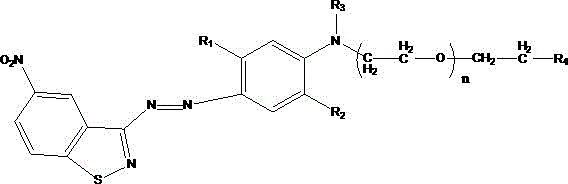

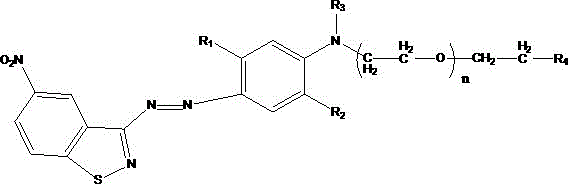

Strong-alkaline-resistant disperse blue dye, compounded mixture thereof, and preparation method thereof

A technology of disperse dyes and disperse blues, which is applied in the direction of azo dyes, organic dyes, monoazo dyes, etc., can solve the problems of high pollution of dyeing waste liquid, non-compliance with energy saving and emission reduction, and high energy consumption, so as to reduce energy consumption and Pollution, excellent fastness and simple production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Add 44g of concentrated sulfuric acid with a mass concentration of 90-98% in the reaction three-necked flask, add 13g of 3-amino-5 nitrobenzisothiazole under stirring, maintain the temperature at 45-50°C, and keep it warm for 1.0 hour to make 3-amino-5 nitro Dissolve all the benzisothiazole until clear; add ice to cool down to 24°C, start adding 21.5g of nitrosylsulfuric acid dropwise, and use ice during the dropwise addition to ensure that the temperature of the material in the reactor remains at 15-20°C; take 1.5-2.0 hours After adding nitrosyl sulfuric acid, keep warm for another 3 hours, and the temperature is still controlled at 15-20°C; before the end of the diazonium reaction, do an end point test; after the test is passed, it will be a diazonium solution, ready to discharge.

[0022] While waiting for the diazo insulation reaction, use a 1000mL three-necked bottle for coupling, and prepare emulsifier OP-10 into a solution with a mass concentration of 10% for late...

Embodiment 2

[0025] Add 40 g of concentrated sulfuric acid with a mass concentration of 90-98% in the reaction three-necked flask, add 10 g of 3-amino-5 nitrobenzisothiazole under stirring, maintain the temperature at 45-50 ° C, and keep it warm for 1.0 hour to make 3-amino-5 nitro All benzisothiazole was dissolved until clear. Add ice to cool down to 24°C, start to add 20 g of nitrosyl sulfuric acid dropwise, and use ice to ensure that the temperature of the material in the reactor is maintained at 10-15°C during the dropwise addition. It takes 1.5-2.0 hours to finish adding nitrosyl sulfuric acid, and then keep the temperature for 5 hours, and the temperature is still controlled at 10-15°C. Before the end of the diazonium reaction, do the end point detection. After passing the test, it is diazo liquid, ready to discharge.

[0026] While waiting for the diazo insulation reaction, use a 1000mL three-necked bottle for coupling, and prepare emulsifier OP-10 into a solution with a mass conc...

Embodiment 3

[0029] Add 50 g of concentrated sulfuric acid with a mass concentration of 90-98% in the reaction three-necked flask, add 15 g of 3-amino-5 nitrobenzisothiazole under stirring, maintain the temperature at 45-50 ° C, and keep it warm for 1 hour to make 3-amino-5 nitro All benzisothiazole was dissolved until clear. Add ice to cool down to 24°C, and start to add 25 g of nitrosylsulfuric acid dropwise. It takes 1.5-2.0 hours to finish adding nitrosyl sulfuric acid, and then keep the temperature for 4 hours, and the temperature is still controlled at 15-20°C. Before the end of the diazonium reaction, do the endpoint detection. After passing the test, it will be diazo liquid, ready to discharge.

[0030]While waiting for the diazo insulation reaction, use a 1000mL three-necked bottle for coupling, and prepare emulsifier OP-10 into a solution with a mass concentration of 10% for later use. Add 240g of water, 10g of emulsifier OP-10 solution with a mass concentration of 10%, and 0....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com