Biological enzymolysis production method for controllable narrow molecular weight functional chitosan oligosaccharide

A technology with narrow molecular weight and production method, applied in the field of biological enzymatic hydrolysis production, can solve the problems of low effective content of chitosan oligosaccharide, unstable molecular weight, long enzymatic hydrolysis time, etc. high effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

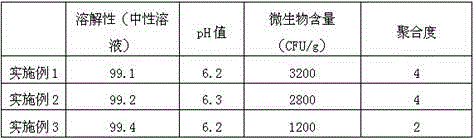

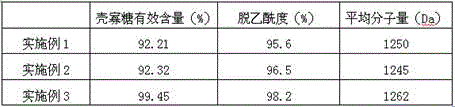

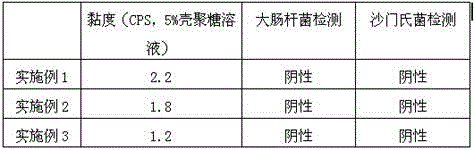

Examples

Embodiment 1

[0036] Example 1 A biological enzymolysis production method of controllable narrow molecular weight functional chitosan oligosaccharide

[0037] Include the following steps:

[0038] Step 1: Media Preparation

[0039] (1) Chitosan medium preparation:

[0040] Chitosan medium, in parts by weight, comprises the following raw materials:

[0041] 15 parts of chitosan, 300 parts of 1.3% acetic acid solution, (NH 4 ) 2 SO 4 3 parts of powder, 20 parts of skimmed milk powder, 500 parts of sterile water;

[0042] Dissolve chitosan in acetic acid solution, then add (NH 4 ) 2 SO 4 powder, skimmed milk powder and sterile water to prepare chitosan medium.

[0043] (2) Preparation of strain fermentation medium:

[0044] Strain fermentation medium, calculated in parts by weight, includes the following raw materials:

[0045] 0.5 parts of soybean flour, 0.03 parts of red algae culture solution, 1.2 parts of rice straw extract, 0.15 parts of corn flour, 0.6 parts of egg white liqui...

Embodiment 2

[0072] Example 2 A biological enzymolysis production method of controllable narrow molecular weight functional chitosan oligosaccharide

[0073] Step 1: Media Preparation

[0074] (1) Chitosan medium preparation:

[0075] Described chitosan culture medium, by weight, raw material comprises:

[0076] 16 parts of chitosan, 350 parts of 1.4% acetic acid solution, (NH 4 ) 2 SO 4 4 parts of powder, 21 parts of skimmed milk powder, 600 parts of sterile water;

[0077] Dissolve chitosan in acetic acid solution, then add (NH 4 ) 2 SO 4 Powder, skimmed milk powder and sterile water are sterilized to prepare chitosan medium.

[0078] (2) Preparation of strain fermentation medium:

[0079] The strain fermentation medium, in parts by weight, raw materials include:

[0080] 0.6 parts of soybean flour, 0.035 parts of red algae culture solution, 1.4 parts of rice straw infusion, 0.17 parts of corn flour, 0.7 parts of egg white liquid, 0.09 parts of pork bone broth, 0.3 parts of cal...

Embodiment 3

[0102] Example 3 A biological enzymatic production method of controllable narrow molecular weight functional chitosan oligosaccharide

[0103] Step 1: Media Preparation

[0104] (1) Chitosan medium preparation:

[0105] Described chitosan culture medium, by weight, raw material comprises:

[0106] 18 parts of chitosan, 380 parts of 1.5% acetic acid solution, (NH 4 ) 2 SO 4 5 parts of powder, 22 parts of skimmed milk powder, 800 parts of sterile water;

[0107] Dissolve chitosan in acetic acid solution, then add (NH 4 ) 2 SO 4 powder, skimmed milk powder and sterile water to prepare chitosan medium.

[0108] (2) Preparation of strain fermentation medium:

[0109] The strain fermentation medium, in parts by weight, raw materials include:

[0110] 0.8 parts of soybean flour, 0.04 parts of red algae culture solution, 1.6 parts of rice straw extract, 0.20 parts of corn flour, 0.8 parts of egg white liquid, 0.1 part of pork bone broth, 0.4 parts of calf serum, 0.07 parts o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Mesh | aaaaa | aaaaa |

| Average molecular weight | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com